520-120 / 530-120H

7

DON’T USE IN DANGEROUS ENVIRONMENTS

Don’t use power tools in damp or wet locations, or

expose them to rain. Keep work area well-lighted.

CHECK THE POSITION OF THE

CABLE DURING OPERATION

Make sure that the cable remains outside

the range of action of the grinding wheel

and is not under tension. Never operate in

the vicinity of other electrical cables.

DIRECTION OF FEED

Feed work into a blade or cutter against

the direction of rotation of the blade or

cutter only. Never advance the chain with

your left hand until the grinding wheel has

moved entirely outside the work area.

MAKE WORKSHOP CHILD PROOF

Use padlocks, master switches. Do not

allow anyone but the user to remain in the

vicinity of the grinder while it is operating

or to touch the grinder supply cable.

ALWAYS KEEP THE HAND GRIPS

CLEAN AND DRY

SECURE GRINDING WHEEL

Make sure the grinding wheel is secured

before starting the grinder. Do not

over-tighten the wheel nut.

SECURE WORK

Make sure that the machine is stable

and rmly secured. Use the vise to hold

chain. This frees both hands for moving

the wheel down to grind the chain.

DON’T OVERREACH

Keep proper footing and balance at all times.

NEVER STAND ON TOOL

Always work in a stable and safe position. Serious

injury could occur if the tool is tipped or if the

cutting tool is unintentionally contacted.

ALWAYS FOLLOW MAINTENANCE

INSTRUCTIONS

CHECK FOR DAMAGED PARTS

Before using the grinder, check to make sure

that all the devices, those for safety and others,

are in good working order. A guard, a wheel or

other part that is damaged should be carefully

checked to determine that it will operate properly

and perform its intended function – check for

alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other

conditions that may aect its operation. A guard,

a wheel or other part that is damaged should

be properly repaired or immediately replaced.

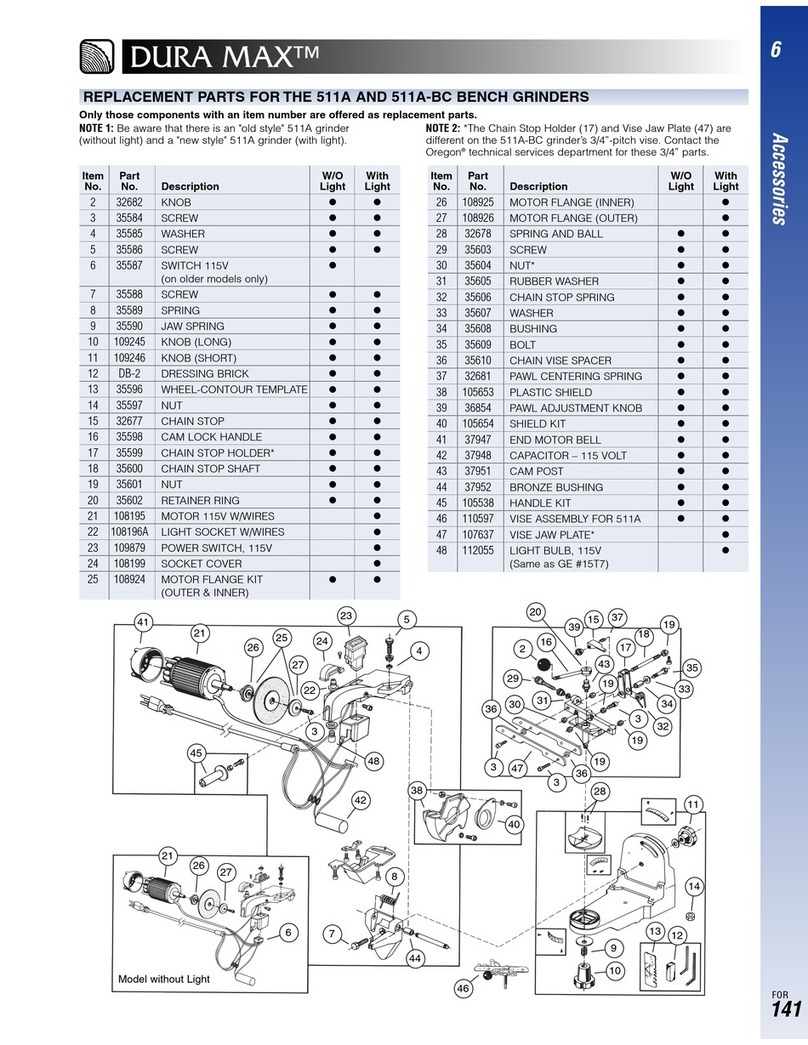

USE RECOMMENDED ACCESSORIES

Consult the operator’s manual for recommended

accessories. The use of improper accessories may

cause risk of injury to persons. Use only anges

furnished with the grinder. To guarantee the

ecient and consistent operation of your grinder,

remember that any worn or broken parts must

only be replaced using ORIGINAL SPARE PARTS.

USE ONLY RECOMMENDED GRINDING WHEELS

CHECK YOUR MACHINE

Never work with a damaged, poorly repaired,

incorrectly tted, or arbitrarily modied grinder. Do

not remove, damage, or disable any safety device.

USE THE RIGHT TOOL

Never use the grinder as a cutter or for

grinding objects other than saw chains.

Don’t force tool or attachment to do a

job for which it was not designed.

EXPERT USERS ONLY

Only lend your grinder to expert users who

are familiar with its operation and correct

use, and always give them the operator’s

manual to read before they start a job.

MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and

safest performance. Follow instructions for

lubricating and changing accessories.

STORE YOUR GRINDER IN A DRY PLACE

Keep it o the ground and out

of the reach of children.

NEVER LET YOUR GRINDER BE

EXPOSED TO RAIN OR DAMPNESS

NEVER USE THE GRINDER IN AN EXPLOSIVE

OR INFLAMMABLE ATMOSPHERE

TAKE THE GRINDER TO YOUR DEALER

When your grinder is not in working order, do not

abandon it on the work site or elsewhere. Take it to

your dealer who will store or dispose of it correctly.

CONSULT YOUR DEALER

Always consult your dealer for any clarication

or important maintenance or repair operation.

NEVER JERK THE CABLE TO

DISCONNECT IT FROM THE OUTLET

Keep the cable away from heat,

oil, and sharp objects.

USE PROPER EXTENSION CORD

Make sure your extension cord is in good

condition. When using an extension cord, be

sure to use one heavy enough to carry the

current your product will draw. An undersized

cord will cause a drop in line voltage resulting

in loss of power and overheating.

SAFETY INFORMATION