HowToUseThis Manual

Always beginwiththe Service Call Procedures,

Section

1.

Perform Initial Actions to identify

andclassifytheproblem.

Then proceed to one of the following sections

ofthemanualtocorrecttheproblem.

Section

2

contains the Status Indicator RAPS.

Use these RAPs ifthecopier

is

notoperational,

such as when a Status Code

is

displayed or

there

is

an improper Indication, or "blank"

display,

etc.

Section

3

is

used to troubleshoot Image

Quality problems.

If

you are not sure of the

type of imagequality defectthat

is

occurring,

use the contents page InSection

3

to find a

defect that best represents the type of defect

that

is

onthecopy.

When usingSection

2

or Section

3,

you may be

directed to Section

4

to perform repair or

adjustment procedures, or to Section

5,

Parts

list.

Next, performtheNormalCallprocedures.

After performing Normal Call or Call Back,

performFinalActionstoensure thatthecopier

meetsthecopyspecifications.

MultinationalConfiguration

Differences

This manual contains informationthat applies

to

US0

(USA),

RX

(Rank Xerox and Xerox

Engineering Systems Europe),

XCL

(Canada),

and

XlA

(Latin America). US0 references

usually apply to

XCL

and XLA. If a USO,

RX,

XCL or XLA copier configuration

is

different,

the specific USO,

XCL,

RX

or XLA information

will beshownbyitself.

"Dry Ink" means the same as "Toner" and

"Tag" meansthesame as "Mod".

RepairAnalysisProcedures(RAPs)

A

RAP

Is

a

series of steps designed tolead you

to the cause of a problem. Ineach step, you

will perform an action or observe an

occurrence. At each step,

a

statement

is

made

thathasaYes

(Y)

or No

(N)

answer.

If the answer

is

NO, perform the action

following the NO. If the answer

is

YES,

proceedtothe nextstep.

Whenseveral itemsare listed, performthem in

theorderlisted.

Proceed through the steps only until the

problem

is

solved. There

is

no need to

continue with the

RAP

after the problem

is

corrected.

Repair

/

Adjustment Procedures

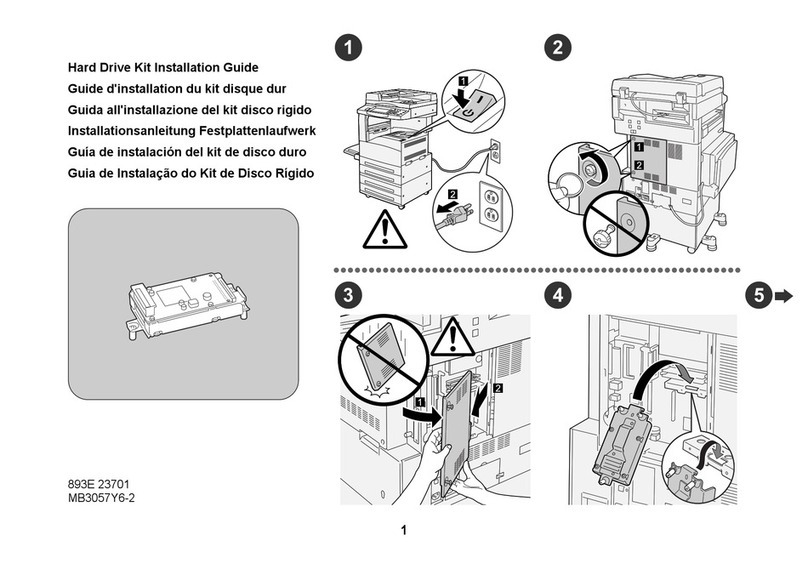

The repair procedures provide detailed steps

on how to remove and replace components.

The adjustment procedures provide detailed

steps on howtocheck and adjust components.

Some copiers have -beenmodified by various

design changes. Each change or modification

is

labeled with a TaglMOD (modification)

number. The TaglMOD numbersare identified

in the Change TagIMOD Index inSection

6

of

thisServiceManual.

When a modificationaffects how

a

particular

procedure

is

performed, the procedure or

steps are identifiedwith either a

W1

TaglMOD

or

a

WIO TaglMOD statement. Each

procedure or step that

is

affected

by

a

modification

is

identifiedwith the statement,

Wl TaglMOD followed by the modification

number. The WI in the statement indicates

that this step must

be

performed on copiers

that are assembled

y&

that specific

modification.

When the procedureor steps are not affected

by

a particular modification, they are

identifiedwith the statement,

WIO

TaglMOD

followed by the modification number. The

WIO

inthe statement indicates that this step

must be performed on copiers that are

assembledwithoutthatspecific modification.

(continued)

lo/%?

Introduction

viii

3050