3

SETTING UP THE XRAY NT1

Setting up a nitro-powered racecar with fully-independent suspension, clutch, and multi-speed transmission — like your XRAY NT1 — is necessary

to make the car perform well. We have developed the NT1 Setup Book to help you set up your NT1 properly and easily. Follow the procedures

carefully, and always make sure that you make equal adjustments on left and right sides of the car.

In addition to describing how to measure and adjust your NT1, the NT1 Setup Book contains detailed information about the effects of setting

adjustments so that you will have a better understanding of them.

Throughout the NT1 Setup Book, we refer to handling effects of the car in the corner, and distinguish three corner sections and three throttle/

brake positions as follows:

Car setup is a complex matter, as all adjustments interact. Fine-tuning your car’s setup will make it faster and often easier to drive near its

performance limit. This means that all the effort you put into preparing your NT1 and optimizing its setup will help pay off in better performance,

results, and satisfaction.

Chassis stiffness (especially torsional) is an important factor when setting up your car. A stiff chassis helps to eliminate chassis flexing and twisting,

which would otherwise introduce another factor that is not easy to measure or adjust. However, chassis stiffness is also a setup tool. By altering

chassis stiffness (for example, using a different engine mount) you can make a “softer” or “stiffer” car that may be more or less suited to track

conditions or driving style. The NT1 features the exclusive XRAY Multi-Flex Technology™ engine mounting system which enables you to adjust the

chassis stiffness.

If you choose to adjust the setup of your NT1, make small adjustments one at a time, and see if you find any improvement in performance and/or

handling with each adjustment. We advise you to keep track of your setup changes, and record which setups work best at different racetracks under

various conditions. You can upload your NT1 setup settings to the XRAY Online Virtual Setup Sheet Database at www.teamxray.com and access your

personal settings from anywhere in the world at any time. You can also benefit from all the setup sheet knowledge and download setup sheets from

XRAY factory team drivers.

Remember that for your NT1 to work and respond to setup changes properly, it must first be in good mechanical shape. Check the well functioning

of critical areas such as the free movement of the suspension, smoothness of shock absorbers, and adjustment and wear of clutch and transmission

parts after each run (and especially after a collision).

After rebuilding the chassis, or in case you become lost with your setup, always return to the last setup you have recorded, or use one of the NT1

setups posted by others.

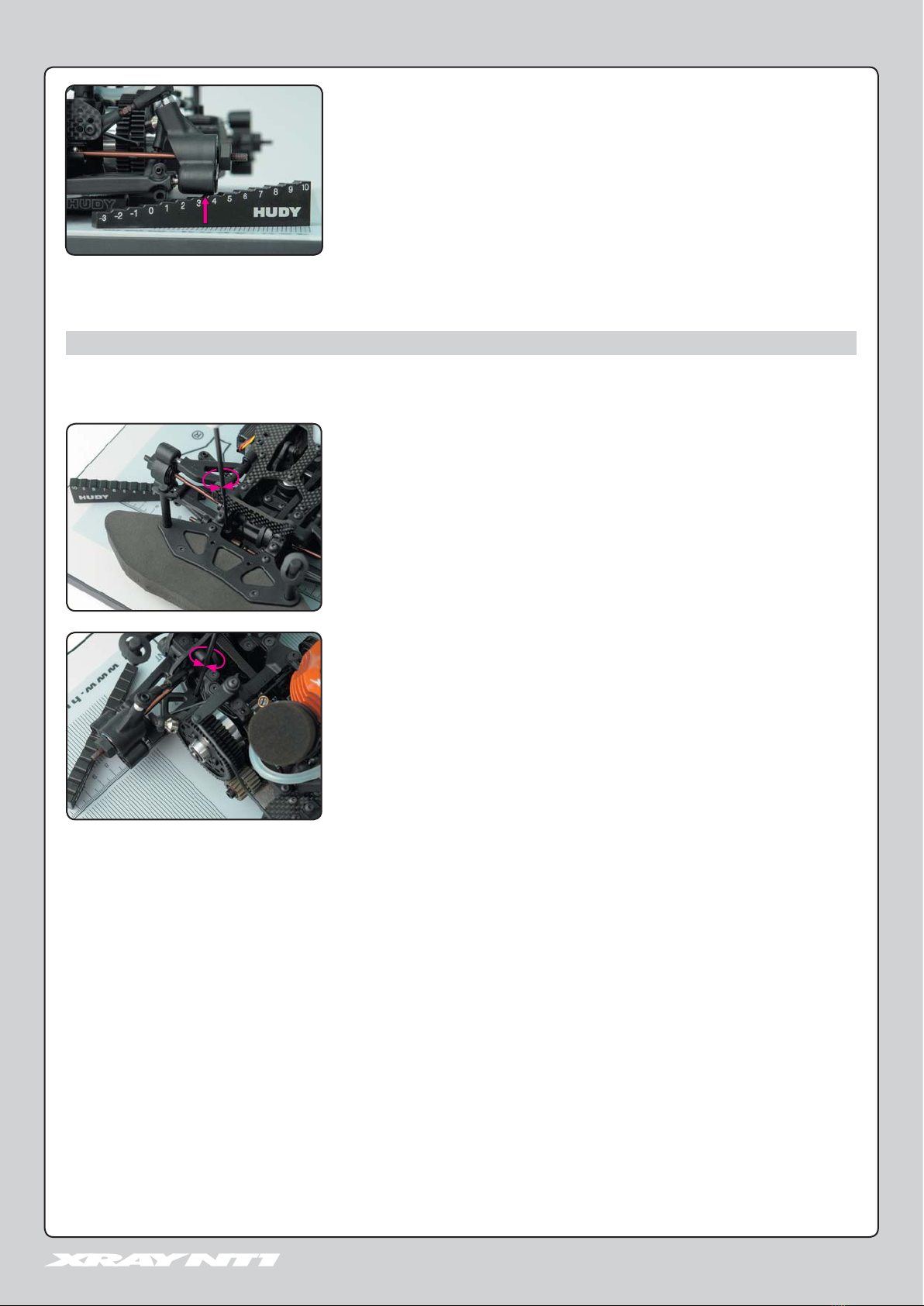

When setting up your NT1, we strongly recommend using the HUDY All-In-One Set-Up Solution #108255,

a high-precision professional set-up system that includes all necessary setup tools and equipment.

107702 DROOP GAUGE SUPPORT BLOCKS

• CNC-machined high-grade aluminum

• precision engraving

• supports chassis when checking downstops

• used with 107712 Droop Gauge

109305 UNIVERSAL EXCLUSIVE ALU. SET-UP SYSTEM FOR TOURING CARS

• CNC-machined alu. and acrylic components

• fully ball-bearing equipped

• precision engraving

• directly measures camber, camber rise, caster, toe, steering throw symmetry

•

easy one-screw assembly/disassembly

PROFESSIONAL TWEAK STATION FOR 1/10 TOURING CARS

• best-in-class integrated solution for

quick and easy track & tweak adjustment

• innovative, easy-to-use, high-tech design

• fully ball-bearing equipped for smoothness and high precision

• ultra-sensitive balance platform gives highly-accurate readings, allowing you to easily and quickly read

and interpret tweak

• rugged CNC-machined aluminum construction, fully assembled

SETTING UP THE XRAY NT1

Corner sections: Throttle/brake positions:

• corner entry • braking

• mid-corner • off-throttle

• corner exit • on-throttle