User Manual

Modbus RTU

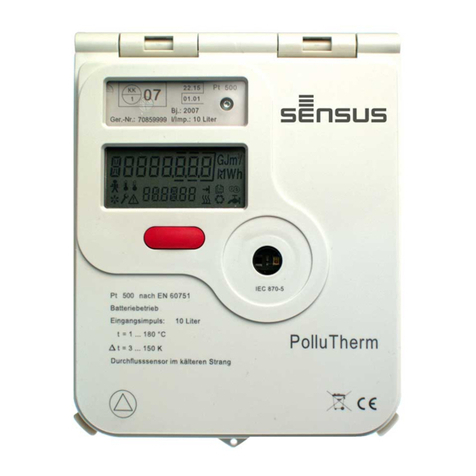

Option module for PolluTherm

M H 6123 INT, page 1

1. Use of the option module

The Modbus RTU option module is used to connect the PolluTherm heat meters

to Modbus RTU network using EIA-485 channel.

Picture 1: Modbus RTU module

The module is based on Modbus RTU Slave protocol which is realized according to newest specifications

published by Modbus. The module EIA-485 network interface is compliant to TIA/EIA-485 standard.

1.1. Power supply

The Modbus RTU module should be powered by AC or DC (polarity insensitive) SELV power supply only.

SELV Power Supply Voltage 12-24 V AC/DC ±10%

Power Supply Terminals 60 and 61 (polarity insensitive)

Power Consumption max. 0.6 W

Typical Supply Current 32 mA @12 V DC

1.2. Communication interface

Connection to Modbus RTU network is realized by using galvanic isolated EIA-485 network interface.

Communication Protocol Modbus RTU

Network Polarity 90 (non-inverting, +) and 91 (inverting, -)

Transmission Speed/Baud Rate (bits per second) 1200, 2400, 4800, 9600, 14400, 19200,

38400, 56000, 57600, 115200

Data Format 8E1 (8 data bits, even parity bit, 1 stop bit),

8O1 (8 data bits, odd parity bit, 1 stop bit),

8N1 (8 data bits, none parity bit, 1 stop bit),

8N2 (8 data bits, none parity bit, 2 stop bits)

Galvanic Isolation between Network and Option Module 299 V

RMS

(0-60 Hz)

Number of Devices per EIA-485 Segment Channel Up to 256 (⅛UL)

EIA-485 Network Topology Bus Topology

EIA-485 Segment Channel Length 1200 m

The default communication parameters are: 9600 bps baud rate, 8N1 data format, Modbus Slave ID – 1.

Use only the dedicated two terminators on both ends of EIA-485 network channel segment. In case of any

question, please contact technical support.

1.3. Environmental requirements

Operating Temperature (ambient) +5 to +50°C

Storage Temperature -10 to +65°C

Operating and Storage Humidity 25 to 90 % RH @50°C, non-condensing