ecocirc XL

P0002557‐rev2

March 2019

QUICK STARTUP GUIDE

______________________________________________________________________

WARNING

This guide does not replace the instruction and operating manual (IOM)

Read the manual carefully before installing and using the product. Improper use of the product can cause personal

injury and damage to property and may void the warranty.

______________________________________________________________________

Startup checklist

Operation Pump Display

1

Mount pump in the system according to flow direction indicated on

the

pump housing and

with motor housing in one of the allowed orientations shown in figure

1.

Make sure the pump is properly aligned with the system piping. Do not attempt to spring

the suction or discharge line in position.

On 3-phase pumps, install two (2) Absolute Pressure Sensors provided with the pump.

-

2

Make sure that power supply matches nameplate electrical ratings of the pump.

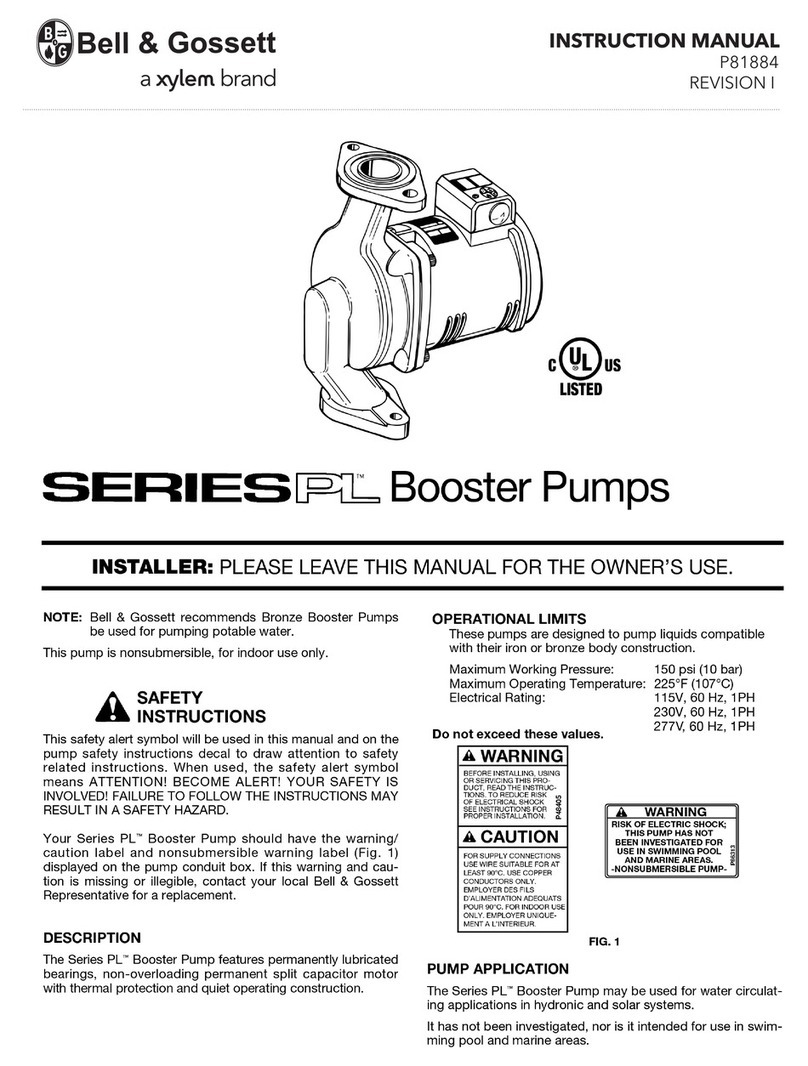

Figure 3 shows wiring terminals for single phase and figure 3a shows for 3-phase pumps.

Please note that 3-phase pumps will rotate only in one direction set at the factory. Wire

swapping is not an option with these units.

-

3 Connect auxiliary input/output signal wires to the pump as indicated.

Power and control wiring must be run in separate channels. -

4

Fill the system with water.

Open all valves in the system to facilitate proper air venting of system piping.

5 Power the pump ON and see that all LEDs are lit and successive submenus start rolling.

(refer to the “Electronic Drive Manual” in case of errors or alarm codes on display)

The display and the LEDs switch-on for 1 second

and then a sequence of submenus for advanced

functions begin to appear.

6

At each power-on, the automatic air venting procedure is executed.

In case of residual air inside the system creating noise or excessive vibration:

oVent the system again.

oRecall the automatic air venting procedure by pressing the up and down arrows

❺simultaneously.

oIf problem is not resolved, refer to instruction manual and/or the electronic drive

manual.

The user interface displays “deg” (degassing)

and a count-down begins until completion of the

procedure:

4DEG - 3DEG - 2DEG – 1DEG

At the end of the air venting procedure, the pump

starts to run with default settings.

7 Set control mode of the pump, by short pressing button ❶(see figure 2 or 2a).

At the user interface, the chosen mode LED will

light up.

Constant pressure mode

Proportional pressure mode

Fixed speed mode

Night mode

8 Short press button ❺to display the actual set points (see figure 2 or 2a). On display the actual setpoint starts blinking

9 Change values as desired with arrow buttons ❺(see fig. 2 or 2a) The setpoint stops blinking on display and the

new parameters will be displayed

10 To change the displayed units of measurement, press the button ❸(see fig.2 or 2a)

W

m

3

/h gpm

m ft

rpm

11 To change the unit of measurement of head or flow, press the button ❸for more than

1sec. (see fig. 2)

•

Flow: m

/h ↔gpm (US)

. Head: m ↔ft

12

The user interface can be locked/ unlocked by pressing and holding down the two arrow

setting buttons ❺and the parameter button ❸simultaneously for two

seconds.

The user interface will be automatically locked after ten minutes of pressing the last button.

By pressing any button when the user interface

is locked, the display shows

Unlocked user interface displays: