4

per ANSI B16.1, class 125 for standard anges as indi-

cated. Maximum working pressure for class 30 cast iron,

per ANSI B16.1, is 175 PSI.

Internal combustion engines are variable speed and vari-

able power machines. The power output depends on the

engine speed (RPM) and will be reduced when operat-

ing altitude, and/or the air temperature increases. When

driving the pump at the RPM required to deliver water

into the system piping, the engine must operate within

the Engine Manufacturers minimum and maximum RPM

limits. The power output to supply the pump power

demand must not exceed the continuous power rating

of the engine, after derating for all power consuming

engine accessories, and adjustmaner for installation site

altitude and air temperature.

DRIVE-TRAIN SIZING (BHP)

The BHP Equation is: (Flow x TDH) / 3960 x Eff.)

Note: For internal combustion units the BHP calculation

must be de-rated for the following conditions:

• 20% for continuous duty

• 5% for right-angle drive

• 3% for each 1,000 feet above sea level

• 1% for each 10º F above 60º F.

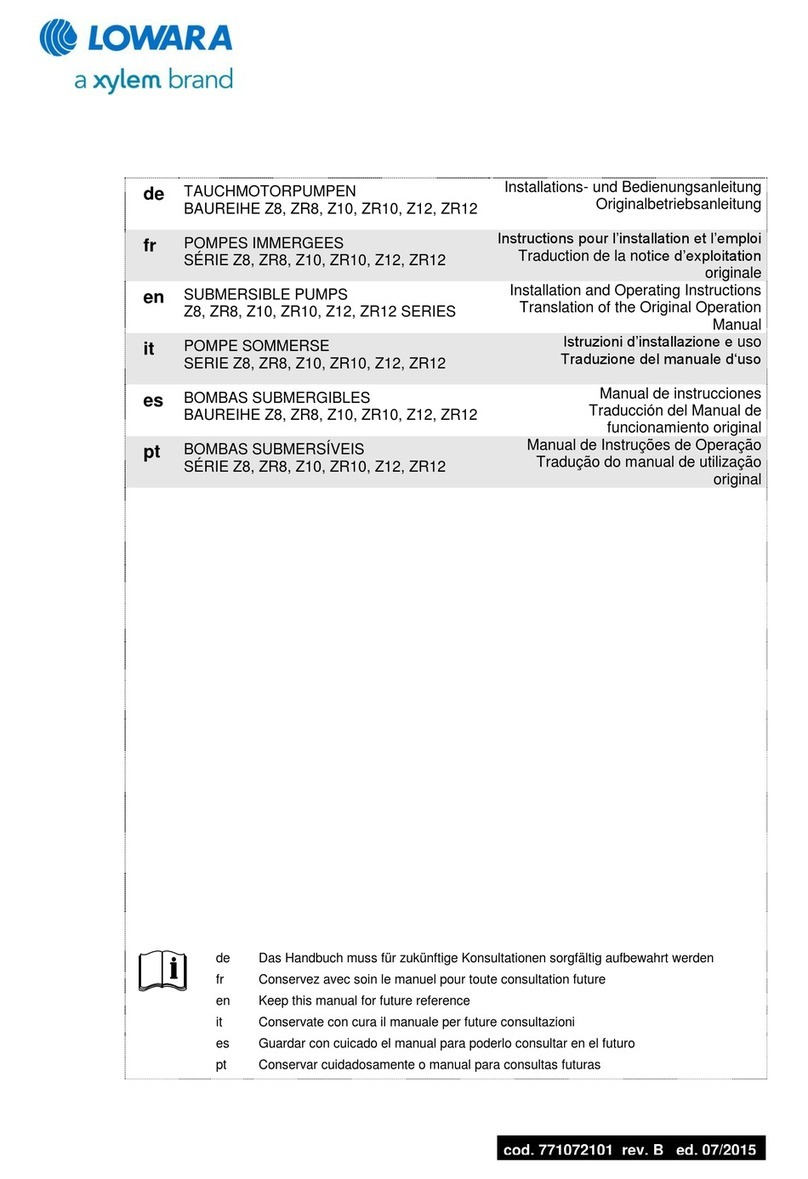

DRIVE-TRAIN SIZING (TORQUE)

Other than sizing an engine for BHP, torque calculations

also are required for proper sizing. Typically the horsepow-

er and torque rating do not follow the same relationship

throughout the usable range of a diesel engine (Figure 2).

The equation for torque (lbs/ft) is (5250 x BHP) / RPM.

Figure 2: HP (◆) vs. Torque (■)

VERIFY MATCH OF PUMP END TO ENGINE

SAE Bracket Size:

Engine drive pumps are available to t engines having a

standard SAE 5 through SAE 1 ywheel housing.

For a new engine, the engine supplier can provide the

SAE housing number.

For an existing engine, the ywheel housing bore and

bolt circle can be measured and compared against the

standard SAE housing dimensions listed in Table 1, to

identify the housing SAE number.

• Measure the ywheel housing bore (A), and the bolt

circle (B), as accurately as possible with a tape measure

(to the nearest 1/32 inch).

• Count the number of threaded holes in the ywheel

housing (C). Test the threaded holes with a bolt, to

determine the thread series.

• Compare the measured dimensions (A), (B), and (C)

against Table 1, to determine the SAE number of

the ywheel housing, to be sure it matches the SAE

number of your pump.

(1/4") Grout hole Base

Leveling wedges or shims—left in place

Top of foundation—

clean and wet down

Sleeve

Washer

Lug

(1/2 to 3/4")

Allowance

for leveling

Wood

frame

Grout

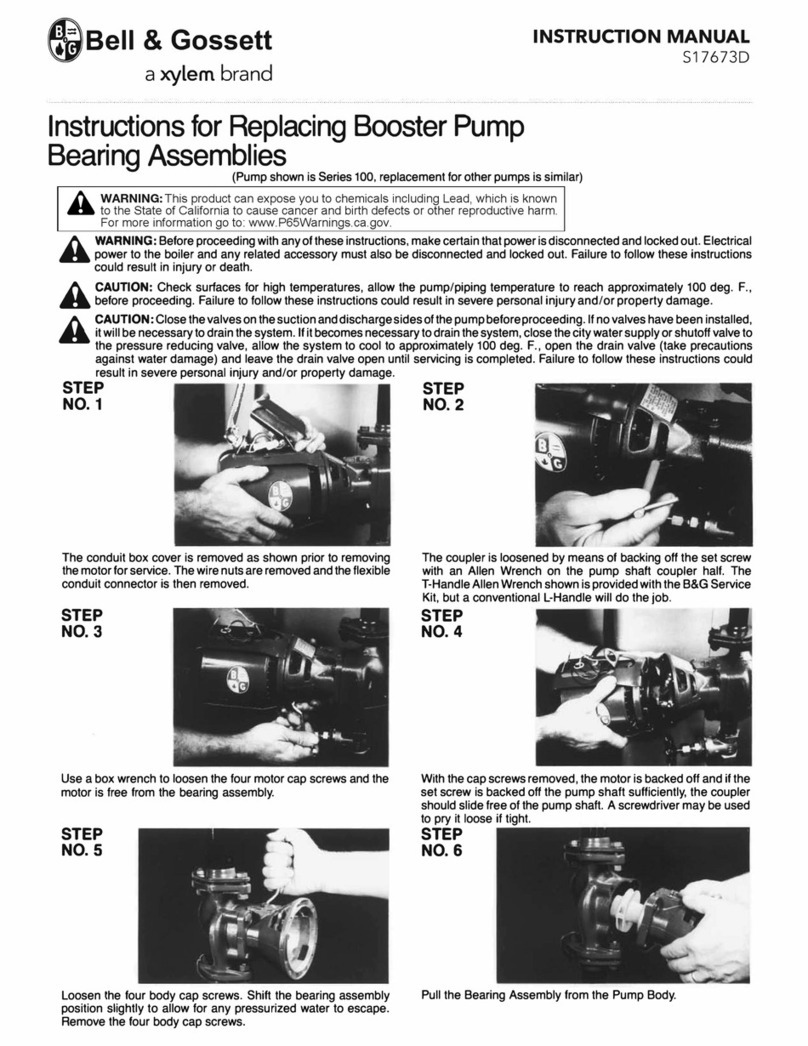

FRAME-MOUNTED UNITS

• A at substantial foundation surface MUST be provided

to avoid distortion and/or strain when tightening the

foundation bolts. A rubber mounting is acceptable to

reduce noise or excessive vibration.

• Tighten motor hold-down bolts BEFORE connecting

piping to pump.

Figure 1

• It is recommended that the baseplate be grouted to a

foundation with solid footing. Refer to Figure 1.

• Place unit in position on wedges located at four points,

two below approximate center of driver and two below

approximate center of pump. Adjust wedges to level

unit. Level or plumb suction and discharge connections.

• Make sure bedplate is not distorted and nal coupling

alignment can be made within the limits of movement

of motor and by shimming, if necessary.

• Tighten foundation bolts nger tight and build dam

around foundation. Pour grout under bedplate mak-

ing sure the areas under the pump and motor feet are

lled solid. Allow grout to harden 48 hours before fully

tightening foundation bolts.

• Tighten pump and motor hold-down bolts before

aligning shaft or connecting the piping to pump.

• Allow grout to harden for 48 hours before tightening 4

foundation bolts.

SAE – ENGINE DRIVEN PUMPS

The SAE engine drive bearing frame is designed to

bolt directly to the ywheel housing for engines with

an SAE no. 1, 2, 3, 4 or 5 mount. The pump shaft exten-

sion is sized for use with couplings bolted directly to the

ywheel. Goulds Water Systems optional couplings are

sized for 6½", 7½", 8", 10", and 14" ywheels. Although

other ywheel mount couplings may be used, it is recom-

mended that the Goulds Water Systems coupling be

used to ensure long and trouble-free operation from

your Goulds Pump.

REQUIREMENTS FOR PROPER OPERATION

Pump End:

When delivering the required capacity (GPM) to the

system piping, the pump must add the amount of Head

required by the system at the capacity. The operating

head-capacity point should be as close as possible to the

highest efciency line shown on the performance curve,

and must be below the head-capacity line labeled “maxi-

mum” RPM. The maximum operaton RPM for the pump is

determined by bearing life, or in some cases, by the pres-

sure limits of the pump. Suction and discharge openings

are NPT tapped for standard pipe, or faced and drilled

500

400

300

200

100

0

1500 1600 1700 1800 1900 2000 2100 2200 2300

RPM

178

176

174

172

170

168

166

164

162

160