1 Preface and Safety

YASKAWA ELECTRIC SIEP C730600 24A V1000 Option CANopen Technical Manual 5

◆Applicable Documentation

The following manuals are available for SI-S3/V CANopen Option unit:

For the drive setup, refer to one of the documentation listed below.

◆Terms

Note: Indicates a supplement or precaution that does not cause drive damage.

◆Registered Trademarks

• CANopen is a registered trademark of the CAN in Automation (CiA).

• Other company names and product names listed in this manual are registered trademarks of those companies.

◆Supplemental Safety Information

Read and understand this manual before installing, operating, or servicing this option unit. The option unit must be installed according to this

manual and local codes.

The following conventions are used to indicate safety messages in this manual. Failure to heed these messages could result in serious or possibly

even fatal injury or damage to the products or to related equipment and systems.

Option Unit

V1000 Option CANopen Installation Manual

Manual No. : TOBP C730600 24

Read this manual first.

The installation manual is packaged with the CANopen Option and contains a basic overview of wiring, settings, functions, and

fault diagnoses.

V1000 Option CANopen Technical Manual (this book)

Manual No. : SIEP C730600 24

The technical manual contains detailed information and command registers.

To obtain the technical manual access these sites:

Europe: http://www.yaskawa.eu.com

Japan: https://www.e-mechatronics.com

Other areas: contact a Yaskawa representative.

Yaskawa Drive

V1000 Series AC Drive Technical Manual

Manual No. : SIEP C710606 16

This manual describes installation, wiring, operation procedures, functions, troubleshooting, maintenance, and inspections to perform before operation.

To obtain instruction manuals for Yaskawa products access these sites:

Europe: http//www.yaskawa.eu.com

Japan: https//www.e-mechatronics.com

Other areas: contact a Yaskawa representative

V1000 Series AC Drive Quick Start Guide

This guide is packaged together with the product. It contains basic information required to install and wire the drive. This guide provides basic

programming and simple set-up and adjustment.

Drive: Yaskawa AC Drive -V1000 Series

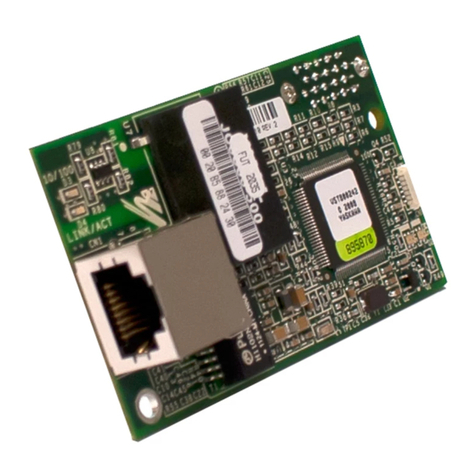

CANopen Option: Yaskawa AC Drive -SI-S3/V CANopen option unit for the Yaskawa V1000 drive

DANGER

Indicates a hazardous situation, which, if not avoided, will result in death or serious injury.

WARNING

Indicates a hazardous situation, which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a hazardous situation, which, if not avoided, could result in minor or moderate injury.

NOTICE

Indicates an equipment damage message.

STOP

(Hz)

(Hz)

(A)

(V)

V1000

ᵄᢙᜰ

ᱜォㅒォㆬᛯ

ജᵄᢙ

ജ㔚ᵹ

ജ㔚

ࡕ࠾࠲

ࡌࡈࠔࠗ

࠶࠻ࠕ࠶ࡊ

ࡄࡔ࠲⸳ቯ

ࠝ࠻࠴ࡘ࠾ࡦࠣ

ᝪ߃ઃߌޔㆇォߩ೨ߦߪᔅߕขᛒ⺑ᦠࠍ⺒ߎߣޕ

ㅢ㔚߅ࠃ߮㔚Ḯㆤᢿᓟ

5

ಽએౝߪࡈࡠࡦ࠻ࠞࡃࠍ

ᄖߐߥߎߣޕ

400V

⚖ࠗࡦࡃ࠲ߩ႐วߪޔ㔚Ḯߩᕈὐ߇ធ

ߐࠇߡࠆߎߣࠍ⏕ߔࠆߎߣޕ㧔ޓޓኻᔕ㧕

ߌ߇㧚ᗵ㔚ߩ߅ߘࠇ߇ࠅ߹ߔޕ

ෂޓ㒾