Yaskawa Electric America, Inc. – www.yaskawa.com

IG.V7.26, Page 3 of 11

Date: 05/24/2010 Rev: 10-05

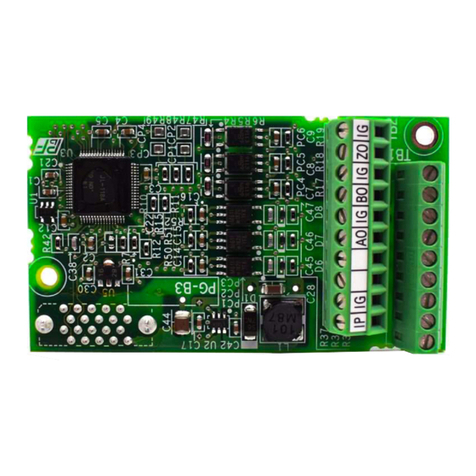

V7 EtherNet/IP Option Kit

CM093

The V7 EtherNet/IP Option Kit includes 3 ferrites which must be mounted to the

Ethernet cable, incoming power leads, and motor leads. See Section 13, steps b

and c.

14. Configure the EtherNet/IP network

a. The default configuration option for the EtherNet/IP Option Kit is DHCP

(Dynamic Host Configuration Protocol). Thus there must be a DHCP

Server connected to the network in order to have the IP address of the

EtherNet/IP Option Kit set. For detailed information on how to set up the

Rockwell BOOTP/DHCP Server on a PC refer to the appropriate

Rockwell document or Yaskawa’s Application Note AN.AFD.10.

b. If the network configuration requires that devices have a static IP

address, the EtherNet/IP Option Kit’s configuration can be changed to

USER and the appropriate static IP address can be entered via the

EtherNet/IP Option Kit’s web pages as shown below.

Note that the EtherNet/IP Option Kit must first have been assigned an IP

address via DHCP server before its configuration can be changed.

15. Configuring a PC with a static IP address

a. Select an existing connection or create a new network connection for

communication with the EtherNet/IP Option Kit.

1. Select Start ⇒Settings ⇒Network Connections from the task bar

in the Windows OS.

2. Select the network connection to be used.

b. Right click on the network connection and select Properties from the

drop-down menu.

c. Select Internet Protocol (TCP/IP) from the components displayed.

Note: If a TCP/IP selection is not available, it may be installed by

selecting Install. Administrator access to the PC and the OS

operating system installation CD-ROMs may also be required.

1. Select Properties.

Note: If the PC is on a building or office network, disconnect it from

that network before proceeding. Record the existing network

settings. If the network connection already has an IP address

assigned on the EtherNet/IP Local network, ignore the following

instructions and just click on Cancel.

2. Select the Use the following IP address radio button.

3. Enter the IP address of a vacant IP address on the EtherNet/IP Local

Network (192.168.1.19 in this example).

4. Enter the subnet mask for the EtherNet/IP Local Network

(255.255.255.0 in this example).

5. Check the system network schematic or with your network

administrator to ensure that the IP address does not already exist on

the network.

6. Once the IP address and Subnet mask are entered, select OK.

Note: It may be necessary to reboot the PC in order for the changes

to take effect.

16. Accessing the EtherNet/IP Option Card web pages

The browser interface to the EtherNet/IP Option Kit can be used for configuring

the card or for network and drive information and diagnostics. To access the web

pages:

a. Obtain the IP address of the desired drive and enter that IP address in the

browser address bar. Hit Enter. The IP address of the desired drive is

192.168.1.20 in this example.

b. The main web page should be displayed.

IP address: 192.168.1.19

Subnet mask: 255.255.255.0