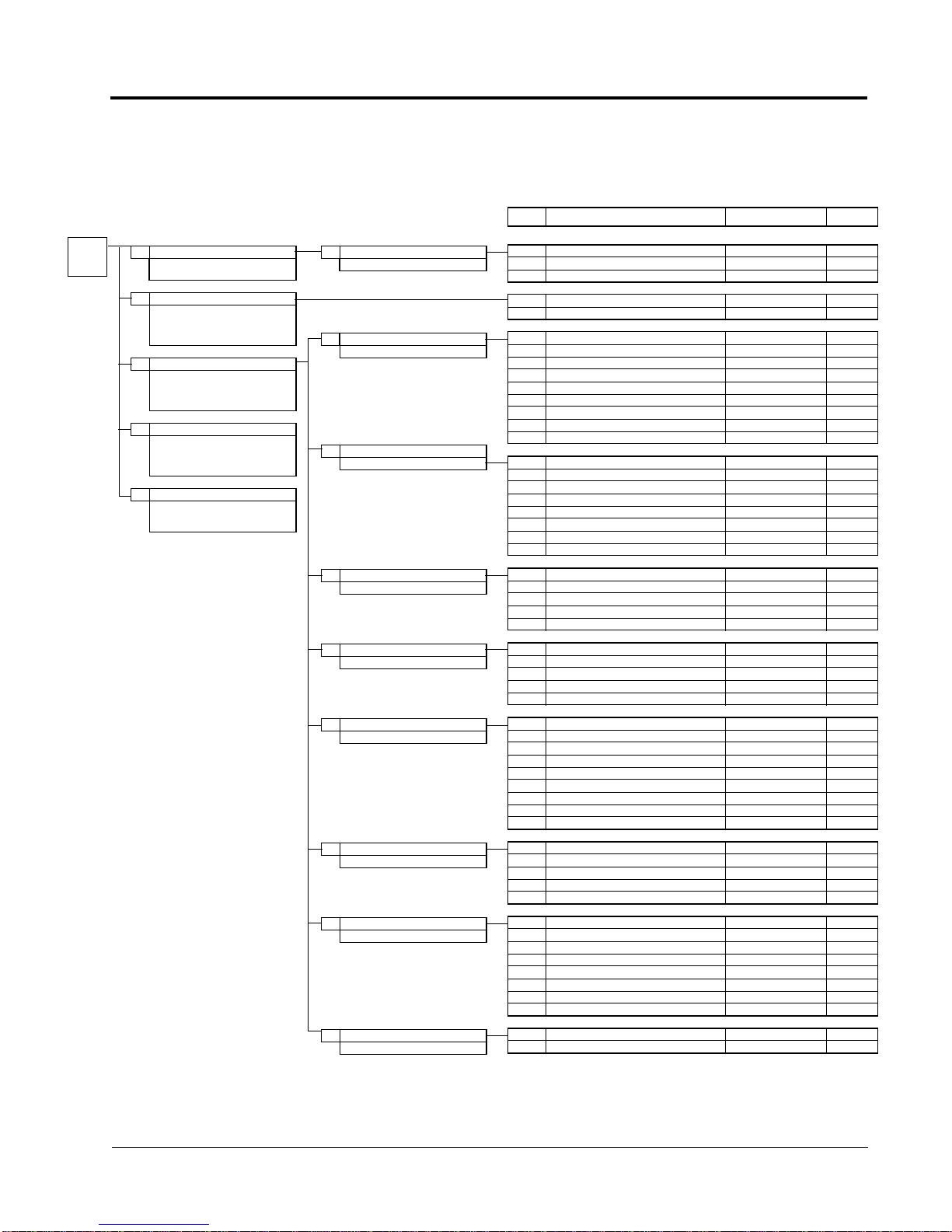

VS-616G5 Programming Manual 7

Menu Operation

Inverter operation is enabled.

Inverter status is displayed.

AInitialize

Language selection in LCD display.

Constant access levels, control method

selection and initializing passwords.

Programming

Parameters are set/read. Items to be set/

read vary depending on the access level

setting.

Auto-tuning

Motor parameters are automatically set

by inputting turning data (motor name-

plate values) when performing vector.

Modified Constants

Only parameters that have been changed

from the factory setting are set/read.

UMonitoring Items

Monitor

BApplication

Application

CTuning

Tuning

DReference

Reference

EMotor Parameters

Motor

FOption

Option

HControl Circuit Terminals

Terminal

LProtection

Protection

ODigital Operator

Operator

Group Function Display Access Level

U1 Status monitoring Monitor Q, B, A

U2 Fault trace Fault Trace Q

U3 Fault history Fault History Q

A1 Initialization Initialize Q

A2 User setting parameter User Parameters A

B1 Operation method selection Sequence Q, B, A

B2 DC injection braking DC Braking B

B3 Speed search Speed Search A

B4 Timer function Delay Timers A

B5 PID control PID Control A

B6 DWELL function Reference Hold A

B7 Droop control Droop control A

B8 Energy-saving control Energy Saving A

B9 Zero Servo Zero Servo A

C1 Accel/decel time Accel/Decel Q, B, A

C2 S-curve characteristics S-curve Acc/Dec A

C3 Motor slip compensation Motor-slip Comp B. A

C4 Torque compensation Torque Comp B, A

C5 ASR ASR Tuning B, A

C6 Carrier frequency Carrier Freq BA

C7 Hunting prevention Hunting Prev A

C8 Factory-tuning constant Factory Tuning A

D1 Frequency reference value Preset Reference Q, A

D2 Upper/lower limits Reference Limits B

D3 Jump frequency Jump Frequencies B

D4 Sequence Sequence A

D5 Torque reference Torque Control A

E1 V/f pattern V/F Pattern Q

E2 Motor parameters Motor Setup Q, A

E3 Motor 2 control method Motor 2 Ctl Meth A

E4 V/f pattern/2 V/f Pattern 2 A

E5 Motor 2 constants Motor 2 Setup A

F1 PG speed control card PG Option setup Q, B, A

F2 Analog reference card A1-14 Setup B

F3 Digital input card DI-08, 16 Setup B

F4 Analog monitor card AO-08, 16 Setup B

F5 Digital output card DO-02 Setup B

F6 Digital output card DO-08 Setup B

F7 Pulse monitor card PO-36F Setup B

F8 SI-F/G card SI-F/G B

F9 DDS-B/SI-B card DDSS/SI-B B

H1 Sequence input Digital Inputs B

H2 Sequence output Digital Outputs B

H3 Analog input Analog Inputs B, A

H4 Analog output Analog Outputs B

H5 MODBUS communication (RS-485) Serial Com Setup A

L1 Motor electric thermal overload relay Motor Overload B

L2 Momentary power loss ride-through PwrLoss Ridethru B, A

L3 Stall prevention Stall Prevention B, A, F

L4 Frequency Detection Ref Detection B, A

L5 Fault retry Fault Restart B

L6 Overtorque detection Torque Detection B, A

L7 Torque limit Torque Limit B

L8 Hardware protection Hdwe Protection B, A

O1 Display selection Monitor Select B, A

O2 Key selection Key Selections B, A

VS-616G5 Parameter Tree

VS-616G5 Parameter Tree