The RecoverX is a VAPOR ONLY

recovery unit. It will not tolerate liquid.

Use your RecoverX to pull vapor refriger-

ant directly out of the system and transfer

it into your recovery cylinder.

Vapor recovery can be done by connect-

ing to the low pressure system suction

service port (Vapor port) side of the sys-

tem. See diagram on following page.

Follow the steps below:

1) Ensure the recovery unit Power

Switch is off (○) and power to the

system to be serviced is off.

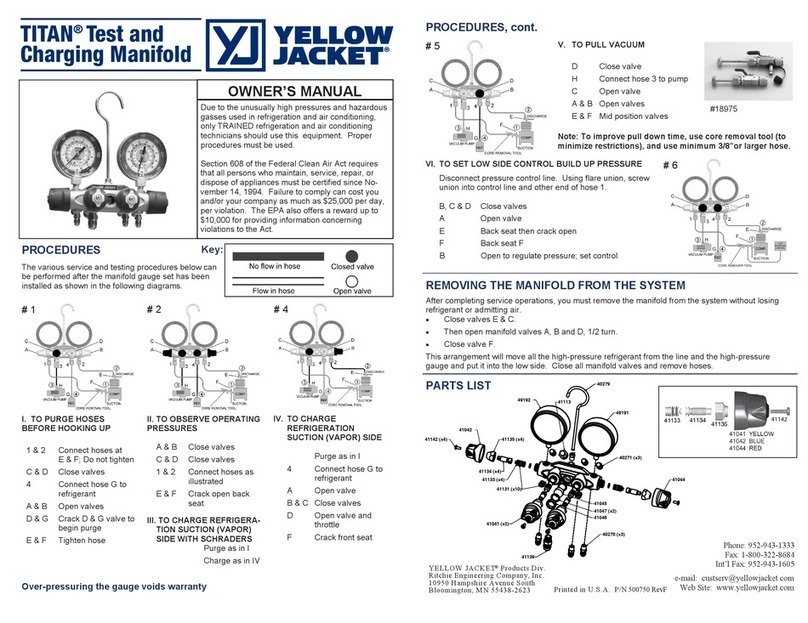

2) Connect the recovery unit, manifold

set, the system to be serviced, and the

recovery tank as shown on page 5.

3) Open the valves on the recovery

cylinder.

4) Turn the Bypass Valve to “OPEN.”

5) Turn the Power Switch on (׀) .

6) Turn the Bypass Valve clockwise to

“CLOSED.”

7) Slowly open the low pressure valve

on the manifold set, regulating the

suction pressure at no more than 40

psi. This will prevent the compres-

sor from stalling.

8) Monitor the manifold low-pressure

gauge. Once the pressure has reached

the required vacuum level, recovery

is complete.

9) Turn the Power Switch off (○).

10) Wait five (5) minutes to ensure the

pressure does not rise.

11) If the pressure rises above the re-

quired vacuum level, continue the

recovery at Step 4.

12) If the pressure remains below the

required level, close the low-pressure

valve on the manifold set and the

recovery tank valves. Disconnect the

hoses.

13) Because oil can be removed from the

HVAC system during recovery, the

Oil Drain port should be drained after

every usage. By draining this oil into

a measuring device, it can be deter-

mined how much refrigerant oil was

removed from the HVAC system.

See the “Oil Level Check” procedure

on page 7.

Operating Guide

Restart Procedure

Liquid refrigerant will flush the oil from the

compressor sump and cause the compressor

to seize or could damage the compressor

valve plates.

The RecoverX is designed for recovery of

vapor refrigerant only. It can also be used

for the traditional push-pull method of

recovering liquid refrigerant.

CAUTION: This unit IS NOT designed for the direct recovery of liquid refrigerant.

If the recovery unit was stopped during

operation, it may be necessary to balance

the internal pressures before the unit will

start.

• Turn Power Switch off (○).

• Stop refrigerant flow to the suction

port on the unit.

• Open “Bypass Valve”.

• Wait 30 seconds.

• Restart the recovery unit.

• Close “Bypass Valve”.

• Resume normal vapor recovery.

4

Troubleshooting Guide

Problem Possible Cause Solution

Compressor will not

start

• Power cord not plugged in • Plug in to energized 110V receptacle

• 110V receptacle not energized • Check 110V receptacle for power

• High Pressure Switch not reset • Reduce discharge pressure and reset.

• If switch will not reset, check dis-

charge for restrictions or schrader

core not fully depressed.

• Circuit Breaker is tripped • Reset circuit breaker

• Defective system switch • Replace switch

Unit starts but stops

after a short period

• Restriction on the discharge port • Open valve on recovery tank

• Ensure schrader core on discharge

port is fully depressed

• Check for other restrictions

• High differential pressure across

compressor

• Turn Bypass Valve to “OPEN.”

• Liquid refrigerant present in the

sump of the compressor

• Remove liquid refrigerant from

sump of compressor.

• Compressor oil level is too low

or too high.

• Check oil level and add or drain if

necessary

Unit will not perform

liquid push-pull

recovery

• System to be serviced does not

allow liquid recovery

• Use Vapor Recovery method

Compressor starts but

trips the circuit breaker

upon start up

UL Certified Rates to ARI Standard 740-98

Other Refrigerants:

YELLOW JACKET RecoverX is approved for use with the following refrigerants which

has not been certified for a particular recovery rate.

R-12, R-134a, R-401C, R-406A, R-500, R-401A, R-409A, R-401B, R-412A, R-411A, R

-407D, R-22, R-411B, R-502, R-407C, R-402B, R-408A, R-509.

R12 R134a R22 R500 R502

Vapor lbs./min .24 .20 .29 .24 .24

Liquid lbs./min N/A N/A N/A N/A N/A

Push-Pull lbs./min 10.4 9.3 8.8 9.6 7.6

Vacuum Level 15 in. Hg 15 in. Hg 15 in. Hg 15 in. Hg 15 in. Hg

9