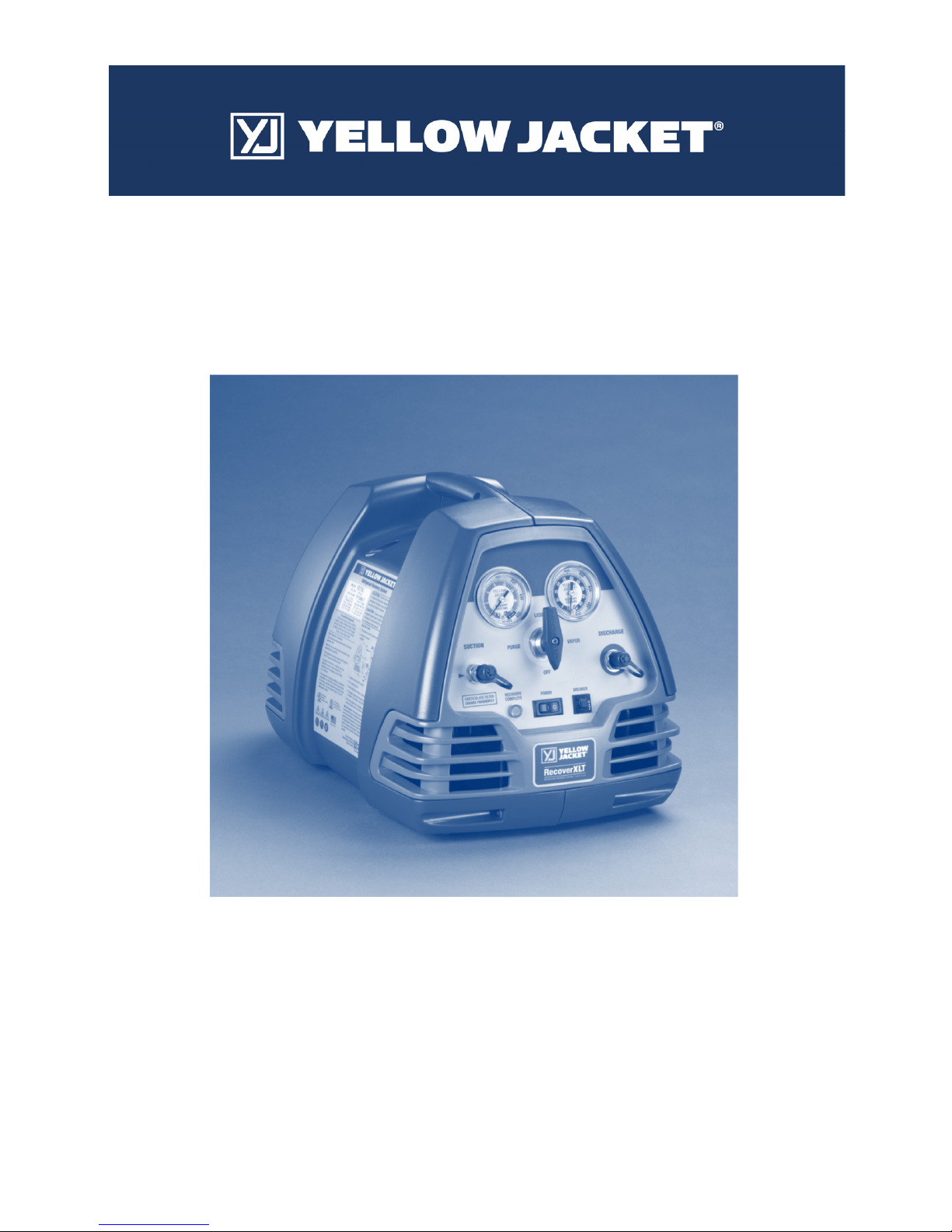

Purging or evacuating the RecoverXL/XLT is one

of the simplest and most important functions.

Reduce the risk of cross contamination and

prolong the life of the RecoverXL/XLT by purging

after every service.

Note: The purge process must be done before

disconnecting the discharge hose from the

RecoverXL/XLT.

For RecoverXLT Models

1) The Low Pressure Switch will shut the unit

off and the lamp will indicate Recovery

Complete when the unit reaches appropriate

vacuum levels. After the unit shuts down, turn

the system switch to off, then rotate the

selector valve clockwise to OFF to equalize

then to PURGE. Turn the system switch on.

Note: The low side gauge should read an

increase in suction pressure, indicating the

refrigerant that was trapped in the machine.

Wait until the Low Pressure Switch again shuts

the unit off at the appropriate vacuum.

2) Close the valve to the recovery tank and shut

the RecoverXLT off.

For RecoverXL Models

1) Monitor the recovery of the system until the

suction gauge indicates the appropriate level of

vacuum. Turn off and rotate selector valve to

OFF to equalize then to PURGE. After the unit

shuts down, turn the system switch to off, then

rotate the selector valve clockwise to OFF to

equalize then to PURGE. Turn the system

switch on.

2) Turn the system switch on.

Note: The low side gauge should read an

increase in suction pressure, indicating the

refrigerant that was trapped in the machine.

Wait until the suction gauge indicates the

appropriate vacuum.

3) Turn the selector system switch off

4) Close the valve to the recovery tank and shut

the RecoverXL off.

Care and Maintenance

Auto Purge Instructions

7

RECOVERY TIPS AND TECHNIQUES

1) To assure the fastest and quickest recovery

possible, use the shortest hoses possible and

avoid hoses with Schrader depressors.

2) Know what kind and the amount of

refrigerant that is going to be recovered. This

is critical to avoid contamination and know

how much refrigerant will be recovered. The

first job of the day usually means a fresh,

empty tank and no cause for worry about over

-filling. However, the last job of the day

means there is already liquid in the tank and

over-filling can be a concern. Over-filling a

recovery cylinder can have disastrous results.

3) Refrigerant responds to heat. Therefore, a

significant increase in the speed of the

recovery process will be obtained if a heat

gun is used, specifically to any spots where

liquid may have accumulated.

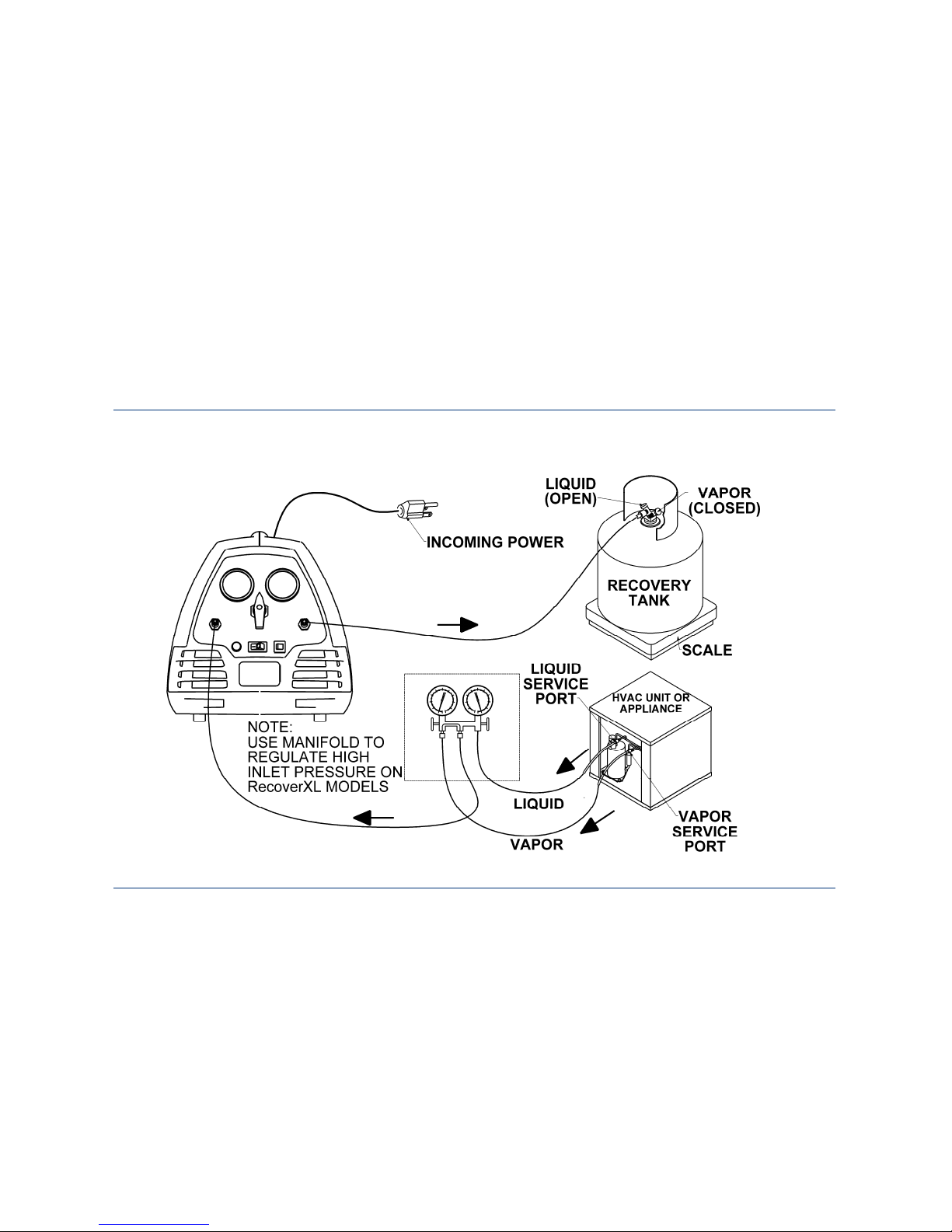

4) Always try to recover liquid first. This is the

preferred method of recovery for the

RecoverXL/XLT , which pumps liquid 5 to 7

times faster in standard liquid mode than

vapor.

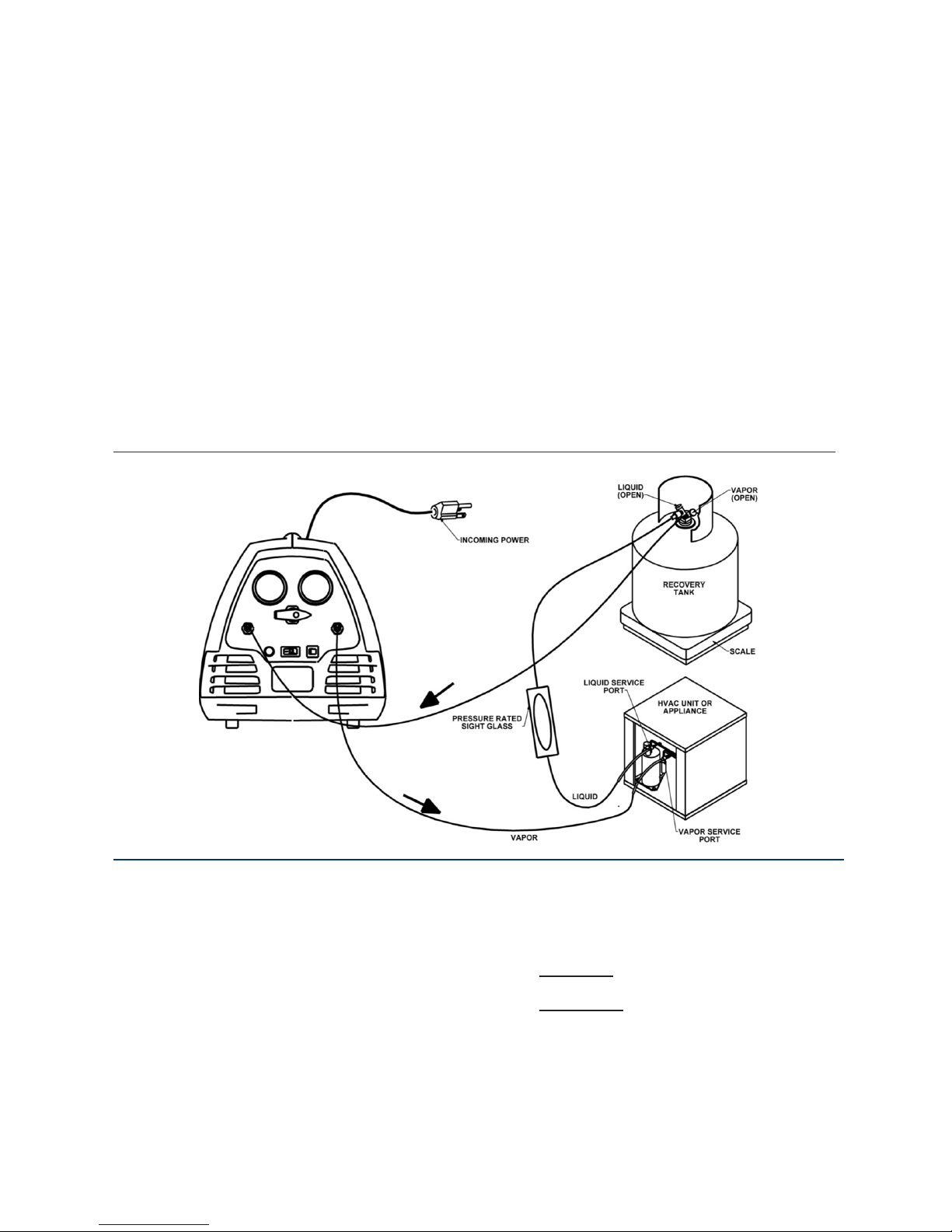

5) If recovering large amounts of refrigerant (20

lbs or more), the push-pull method is recom-

mended. (Note: This process requires the

hoses to be switched before recovery of the

remaining vapor.)

6) Recovery can often be speeded up by

simultaneous recovery from both the high and

low side of the system. Attach short hoses to

both the high and low side of the system and

join them with a BRUTE™ II Manifold or Y

connector to the hose going to the Suction

Port of the RecoverXL/XLT.

7) Protect the RecoverXL/XLT by keeping the

built-in suction filter IN THE MACHINE.

Failure to use the suction filter in the

RecoverXL/XLT will void the warranty.

8) Recovery machines are not vacuum pumps.

For proper evacuation, use a YELLOW

JACKET SuperEvac™ vacuum pump. To

speed up the evacuation process, use the

SuperEvac vacuum pump and a core removal

tool (Part #18975). For more information

contact your YELLOW JACKET wholesaler.