9

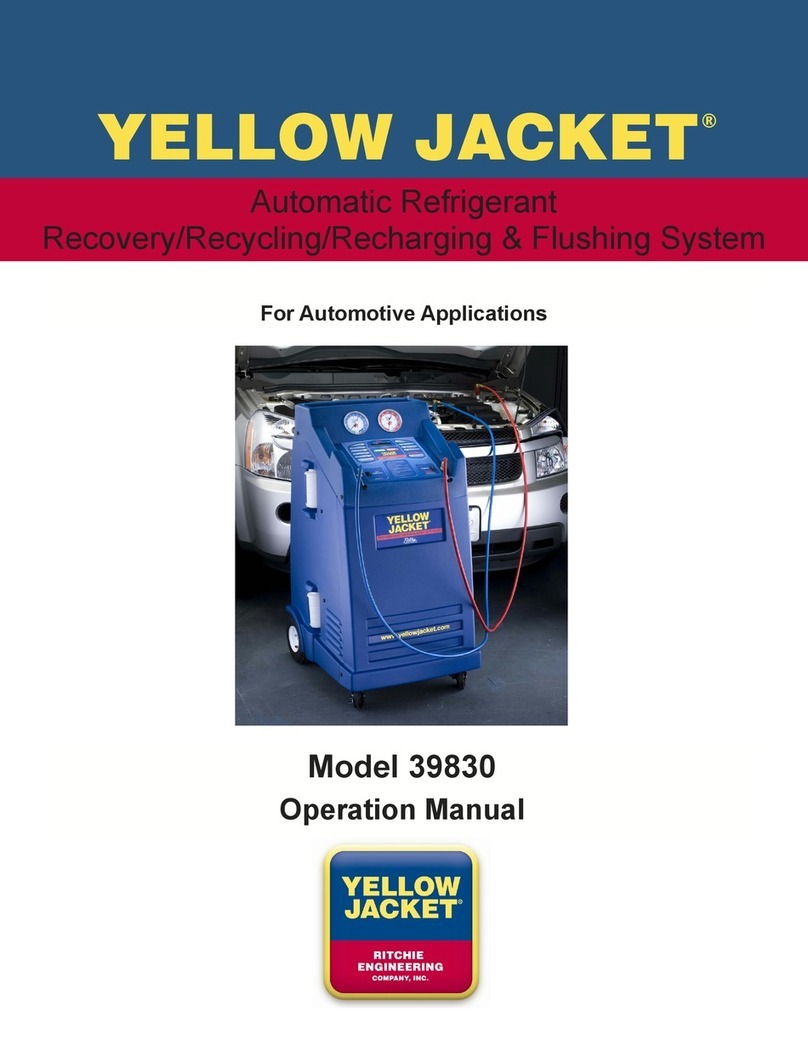

The Full Cycle function of the 37880 is designed to re-

move and recycle all refrigerant in an A/C system by

transferring the refrigerant to the storage tank, remove

moisture in the system by pulling a vacuum, and charg-

ing the system with a precise amount of refrigerant.

MODE 4 Operational Steps

NOTE: If desired, the gauges of the 37880 can now

be used to aid investigation of an A/C system prob-

lem. Ensure the automobile A/C system is turned

off prior to selecting a mode on the 37880.

1. Verify the auto air conditioning system is off.

2. Select Full Cycle in the main menu. The LCD will

read “SELECT VACUUM TIME”

3. When the LCD reads “SET VACUUM TIME,” set

the vacuum time by entering the time using the nu-

meric keypad until the desired time is shown. Press

the ENTER key to continue.

4. When the LCD reads “SET VAC HOLD TIME,” set

the vacuum hold time by entering the time using the

numeric keypad until the desired time is shown.

Press the ENTER key tocontinue.

Note: We recommend 10-15 minimum vacuum time

to ensure proper charging.

NOTE: Vacuum hold time can be bypassed if the

time is set to zero.

1. When the LCD reads “SET CHARGE AMOUNT,”

set the charge amount by entering the amount us-

ing the numeric keypad until the desired time is

shown. Press the ENTER key to continue.

6. When the LCD reads “INJECT OIL AFTER VAC-

UUM”, use the left and right arrow keys to toggle

between YES and NO. Select YES or NO and

press the ENTER key to continue.

7. The LCD should read ‘CONNECT SERVICE

HOSES TO VEHICLE’,

8. Press START KEY to begin full cycle operations.

9. The unit will begin to recover as outlined for the Re-

covery Only cycle, and then evacuate the A/C sys-

tem and will beep to indicate the end of the vac-

uum time— if Vacuum Hold is used.

10. Record the vacuum level shown on the low pres-

sure gauge and press START to begin the vacuum

hold time. The hold time will count down on the LCD

and the unit will beep at the end of the hold time. If

vacuum hold time was set to zero, the unit will

transition into charge mode.

11. Record the final vacuum level shown on the low

pressure gauge. If the two recorded levels are dif-

ferent, the A/C system may have a leak and may

not retain refrigerant when charged. The 37880 will

automatically start the charge cycle.

12. The unit will prompt you to “INJECT OIL NOW”

press and hold the START key until the desired

amount of oil is injected into the A/C system.

13. The LCD will display the progress of the charging

process. When the desired charge amount has

been transferred to the A/C system, the unit will

beep.

14. Verify the message on the LCD reads “FULL

CYCLE COMPLETE.”

15. Press the RESET key. The LCD should read

“CHECK OIL LEVELS.” The LCD will read

“HOSES NEED CLEARING”

16. Press the Enter Key. The unit will then prompt you

to “DISCONNECT VEHICLE.”

17. Shut the service valves and disconnect the high

and low side auto service hoses from the auto.

18. Press the ENTER key; the LCD will read

“CLEARING HOSES.”

19. Measure the oil in the oil drain bottle. Dispose of

recovered oil in a proper manner.

20. Press the RESET key to return to the “SELECT

MODE” status.

Model 37889 (Only) - The 37889 model has an inte-

grated micron gauge that can be used to determine the

micron level of the A/C System. The instructions below

will outline how to use this feature.

INTERGRATED MICRON GUAGE (37889 MODEL

ONLY) The 37889 model has an integrated micron

gauge that can be used to determine the micron level of

the A/C system. The instructions below will outline how

to use this feature .

Full Cycle / Vacuum operations– Select micron level by

using the up or down arrows. If you would rather enter

a time for the vacuum cycle press the START key. Use

the numeric keypad to set vacuum time. NOTE: Be-

cause of the location of the vacuum sensor it may be

necessary to set the micron lever lower to compensate

Note: Since the micron sensor is inside the unit and not

attached to the vehicle there will be a difference in the

actual micron reading in the vehicle.

To achieve the best results set the micron number

lower than the micron level you want to reach.

FULL CYCLE