5 6

1. 853A:

A. Preheating station laid out plugged power cord.

B. Move bracket card board, preheat element is placed above the plate, tight-

en the four screws on the bracket, fixed need to preheat components.

C. Turn on the heating switch, the preheat plate heating, set the appropriate

temperature can be preheated.

2. 853AA/853AAA:

A. Preheating station laid out plugged power cord.

B. Move bracket card board, select the appropriate orientation preheat comp-

onents placed above the preheat plate. Note that bracket above three card

board ports,usually use the below one you need to preheat the components

from the hot plate farther, preheat temperature is a little lower.

C. Open the master switch, then open the preheat plate switch set the appro-

priate temperature can be preheated.

D. Preheat station, hot air reworks, soldering station can flexibility combinat-

ion to use. Preheat station, hot air reworks, soldering station three functio-

ns are independent, you can turn off no need part to save energy.

V. Operation

Preheating station part

1. The soldering iron handle on the iron holder.

2. Open the soldering iron power switch, heating elements begin to heating, pre-

ss soldering iron temperature plus button “ ” and minus buttons “ ” to set

the appropriate temperature, when the soldering iron work indicator regular

flash at high speed into the thermostat state can work properly!

3. After work, you can use the residue under high temperature cleaning sponge

cleaning up the soldering iron lips and re-coated with a new layer of solder,

the soldering iron into the iron hp; der can turn off the power!

Soldering station part

1. The hot air gun rework station is laid out handle frame is installed on the side

of the chassis,air gun bracket rack installed in the back of the chassis, fixed to

the handle in the air guns handle frame.

2. Open the back of the chassis whole switch, open air gun switch, air gun begin

heating, press air gun temperature plus button “ or ” and minus buttons

“ or ” to set temperature, adjust the airflow knob to set the appropriate

airflow, gun indicator regularly flashing means the temperature stability will be

able to normal operation.

3. After work, turn off the air gun switch, the machine automatically cut off the air

gun heating body the power to enter the cooling heating element mode. When

the temperature is below 100°C, the air gun display window goes off and stop

the wind.

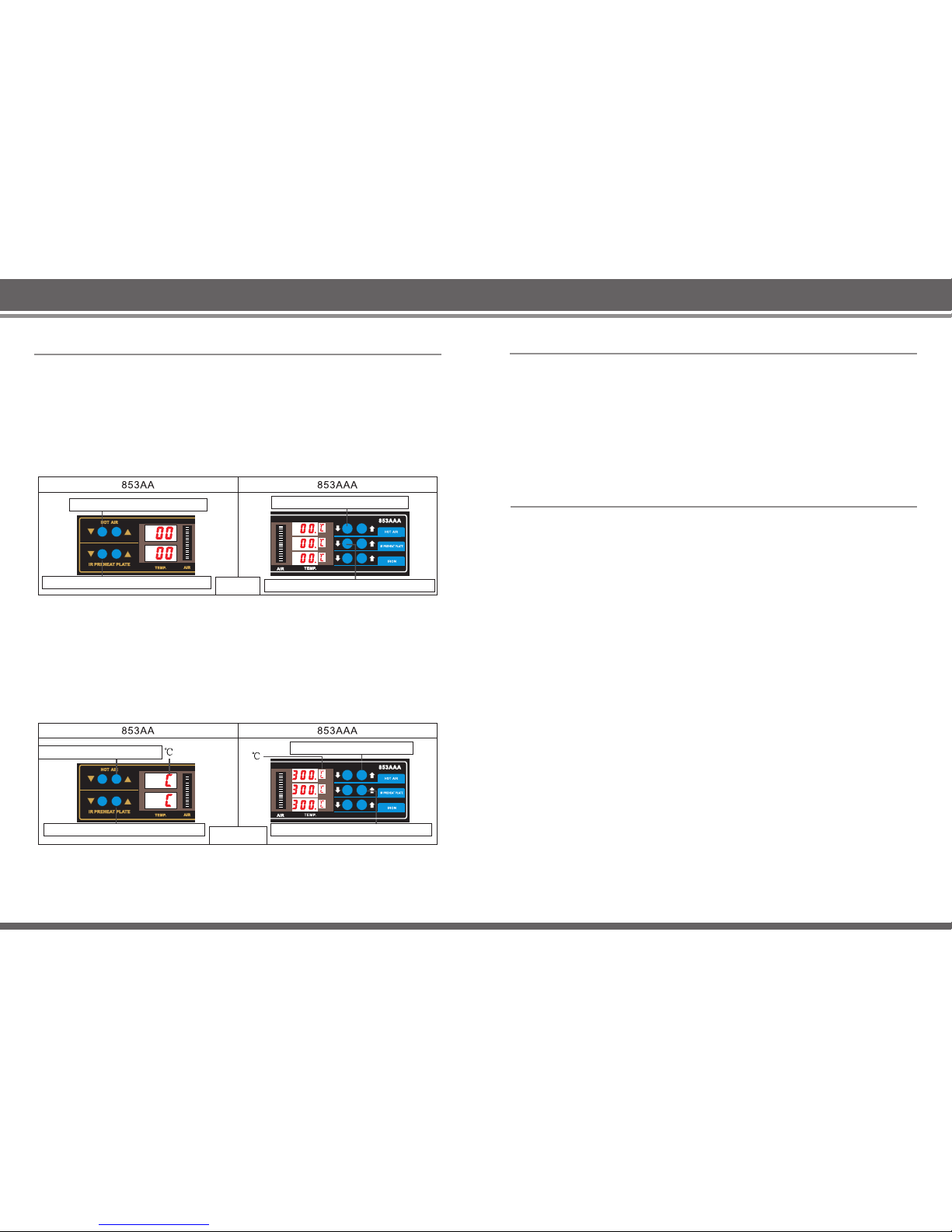

Hot air reworks part 853AA/853AAA

853AAA

Remove the components:

1. The successful rework first removal location of the fault on mother board, and

the solder is heated to the melting point, and then carefully scored the compo-

nents from the board.

2. Heating control is key factor in the rework, the solder must be fully melted, so

as to avoid injury in the removed component plate and copper. While the tem-

perature is not too high ,to prevent the circuit board is heated excessively cau-

sed motherboard distorted.

PCB and component heating:

1. Advanced rework system uses a microcomputer to control the heating process,

with solder paste manufacturer specifications given parameters as possible,

and using a combination of the top and bottom of heating.

2. Bottom heating to complement the board due to pass of heat, while elevated

board temperature; The top heating is used heating components, in addition

the use of coders bottom heater can be eliminated due to local over - heating

the circuit board caused by distortions.

3. Motherboard heating can be used three methods, namely conduction, conve-

ction, and thermalefferma effects. Conduction heating when the heat source

with the motherboard contacts ( for example, using a hot plate ), which on the

rear components of the circuit board not applicable(NA).

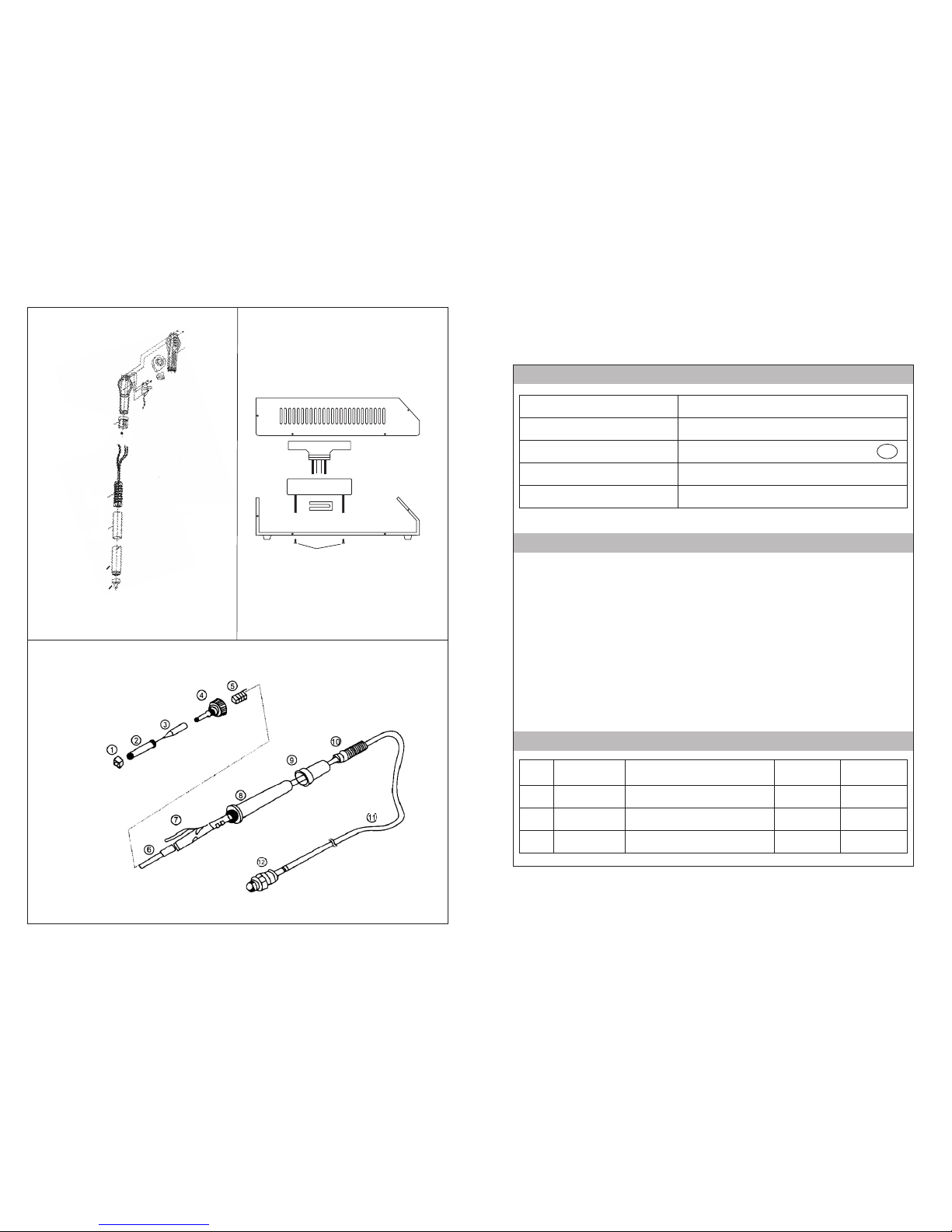

4. Components heating (or top heating) generally use a convection hot air nozzl-

es, careful control of top heating components uniformly heated is extremely

important , especially for small quality components is particularly critical

(Figure 1).

Attached:technical article-Rework the process(for refeerence only)

Air gun with preheating station, to facilitate the large flat IC,dual-panel large compon-

ents de-soldering.

Figure 1

5. Pay attention to avoid rework station nearby components reflow or blow away

small chip components, the hot gas stream discharged by the nozzle must be

isolated with these elements, the thin layer of shielding plate or the mask can

be put in the surrounding components of the reword station. Mask technology

is quite effective,but more trouble consuming, but can be used dedicated BGA

rework nozzles, it can reduce the damage to the components in the vicinity of

the demolition components and circuit boards in the process of unsoldering.