Warning : Working at height is a very dangerous activity which may lead to severe injury or fatality. We

advise that you personally assume the responsibility to learn the use and the safety measures that apply to

this equipment. Remember that there is no better ''instruction'' than that of a trained instructor. Train in

the use of this tool, verify that you have fully understood how it works and if in any doubt, please ask

competent person!

Don’t make any alterations or additions to the equipment without the manufacturer’s prior written consent.

Any repair shall only be made by the manufacturer. The products shall not be used outside its limitations,

or for any purpose other than that for which it is intended.

It is essential for the safety of the user that if the product is re-sold outside Taiwan, the reseller shall

provide instructions for use, for maintenance, for periodic examination and for repair in the language of the

country in which the product is to be used.

If there is reason to doubt your fitness to safely absorb the shock from a fall arrest, please consult your

doctor. Age and fitness seriously affect a worker’s ability to withstand falls. Pregnant women or minors

must not use YOKE hooks or connectors.

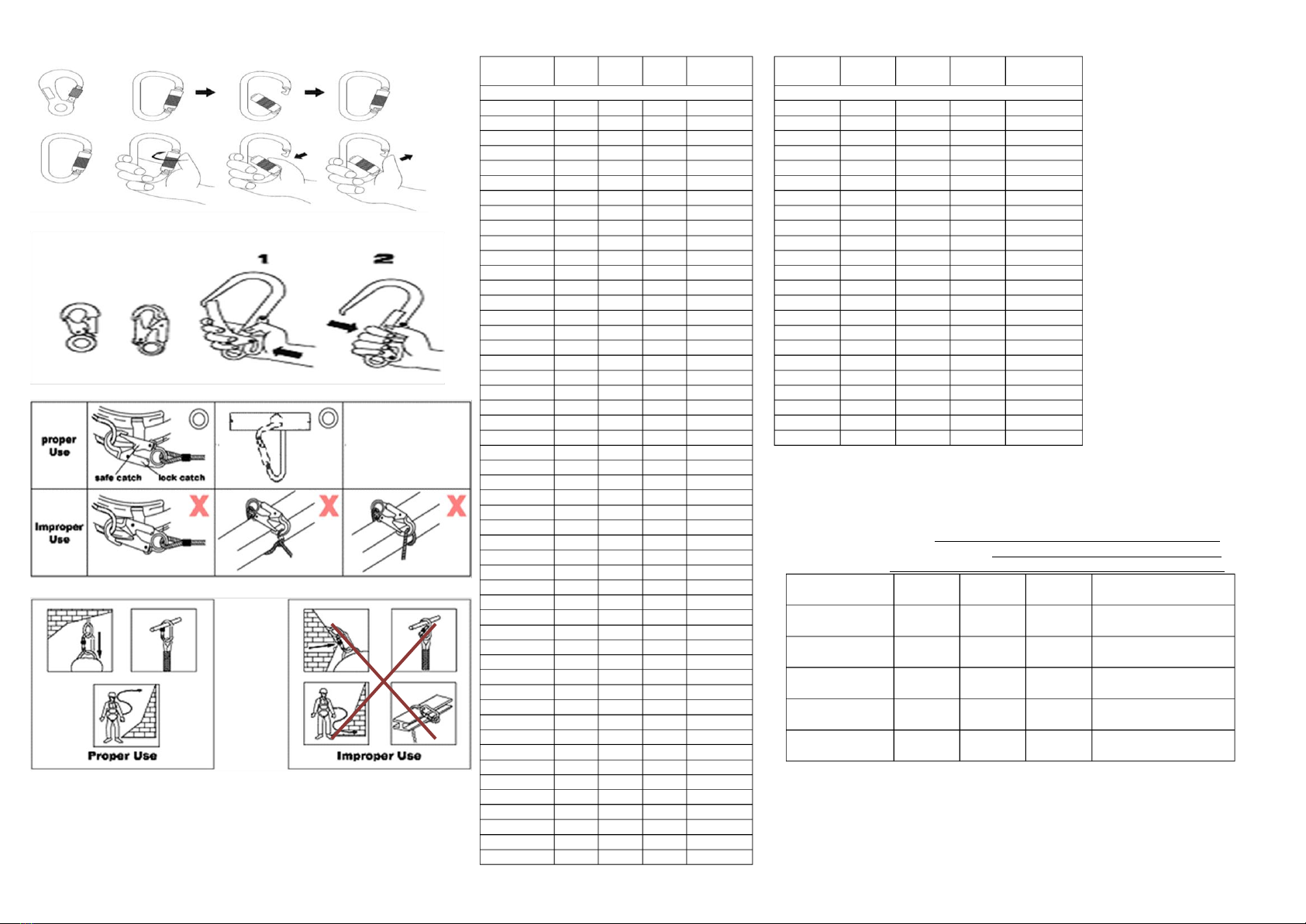

User Instructions for Connectors

Please read these instructions thoroughly before using this

equipment.

1. GENERAL USE INFORMATION

The connector is essential for your safety so we

recommend that you :

*assign it to an individual user whenever possible:

*check it before each use, in particular for: Deformations,

Signs of wear, correct locking system operation.

If you are in any doubt whatsoever about the safe

condition of this product or if the connector has been

used to arrest a fall, it must be essential for safety that it

is withdrawn from use.

Ensure that the instructions for other components used

in conjunction with these products are complied with as

stated by the EC directive 89/686/EEC (personal

protective equipment).

The anchor device or anchor point should always be

positioned, considering both the height of fall and the

extension of the rope in order to avoid possible

obstructions (i.e.the ground). Be sure that the

anchorage strength corresponds to min. Breaking loaded

to 20 kN (EN) or 23kN (ANSI, CSA).

YOKE products are made in accordance with European

Standard No.EN362:2004 or Canada/US Standard No.

CSA Z259.12 & ANSI Z359.12

2. COMPATIBILITY

When used as part of a PPE system against falls from a

height, this connector must be connected to a

compatible connection (example: a correct D-Ring). It

is important to ensure compatibility in order to avoid

possibility of roll-out or disengagement. Only one

personal protective system can be attached to this

connector. This connector is designed for use by one

person only. Ensure that proper fall clearance exists in

order to prevent striking ground or other objects in the

event of a fall.

Note: a connector is considered to have a compatible

connection when the connectors have been designed

to work together and that their shape/size do not cause

gates to inadvertently open. All connections must

fully close and lock.

3. MEANING OF MARKING AND / OR SYMBOLS:

CE marking and Notified Body number

Batch number (3 Capital letters)

Year code of manufacturing year (2 digits)

Manufacturer name or abbreviation name

4. MAINTENANCE, SERVICING AND STORAGE.

Cleaning : If soiled, rinse in clean water ( maximum

temperature 40°C ) with mild neutral detergent. When

the equipment becomes wet, either from being in use

or when due to cleaning, it shall be allowed to dry

naturally, and shall be kept away from direct heat.

Lubrication : Lubricate mobile parts (e.g. spring and

rivet ) with a silicone based lubricant only. This

should be carried out after cleaning and

drying. Avoid any oil contact with textile parts.

Storage : During transportation or after any

necessary cleaning, drying and lubrication, store

unpacked in a cool, dry, dark place in a chemically

neutral environment away from excessive heat or

heat sources, high humidity, sharp edges, corrosives

or other possible causes of damage. Do not store

wet. Avoid U.V. radiation, and salt environments.

Service Live: It is very difficult to estimate

obsolescence due to local use and storage

conditions, however, the following may reduce the

strength greatly and the lifespan to as little as one

use: incorrect use, severe fall arrest, mechanical

deformation, fall from a height on the connector,

general wear and tear, gate malfunction, chemical

contamination, heat contamination.

5. RECORDS (RECORD-CARD)

The product can be traced through Test Certificate

issued by YOKE. The Test Certificate shows Model

/ type identification (i.e. Item Number), the name and

contact details of the manufacturer, and means of

identification (batch or serial number).

6. RESCUE PLAN

It is important to make plan for a rescue in the

event of a fall BEFORE starting to work. Ensure

that a rescuer plan is discussed with a competent

person and that this plan takes into account:-

Dangers from swing falls- Avoidance of exposure

of connecting components to sharp edges

- Removal from service for any components

subject to a fall.

It is also important to ensure that the employer

has a documented rescue plan and has the ability

to implement it.

7. YOKE'S CONNECTORS USE AND

MAINTENANCE

The connector you have just acquired is used to

connect personal protective equipment to some

other system component (harness, lanyard, fall

arrester, anchorage point, etc.)

When employing a connector that has a manual

closing gate (example –screw gate), it is

recommended that it be

used in situations that DO NOT require frequent

attachment and removal during a working period.

Care should be taken to avoid loading a connector

across its gate.

When assessing the appropriateness of a fall arrest

system, the length of this connector should be taken

into consideration concerning all distance.

Before first use it is recommended to check carefully

that the equipment is compatible with the other

system components.

In use, protect your connector against any hazard in

the work environment, e.g. thermal or electric

shocks, mechanical impact, acid splash and so forth.

IT IS ESSENTIAL TO ENSURE BEFORE USE

THAT THE

RECOMMENDATIONS SPECIFIC TO EACH PART

ASSOCIATED WITH THIS

PRODUCT ARE COMPLIED WITH, AS SPECIFIED

IN THE MANUAL.

IMPORTANT :

These instructions should be supplied to each

person using this product. This connector must be

inspected by a competent person prior to each use

by the user and at least once a year by the

manufacturer or by an authorized person. The

inspection should be recorded on the enclosed

schedule

Involved notified Body:

design and controlling stage:

INSPEC International Limited (0194)

56 Leslie Hough Way

Salford

Greater Manchester

M6 6AJ United Kingdom