RMG TRZ 04 User manual

Reliable Measurements of Gas

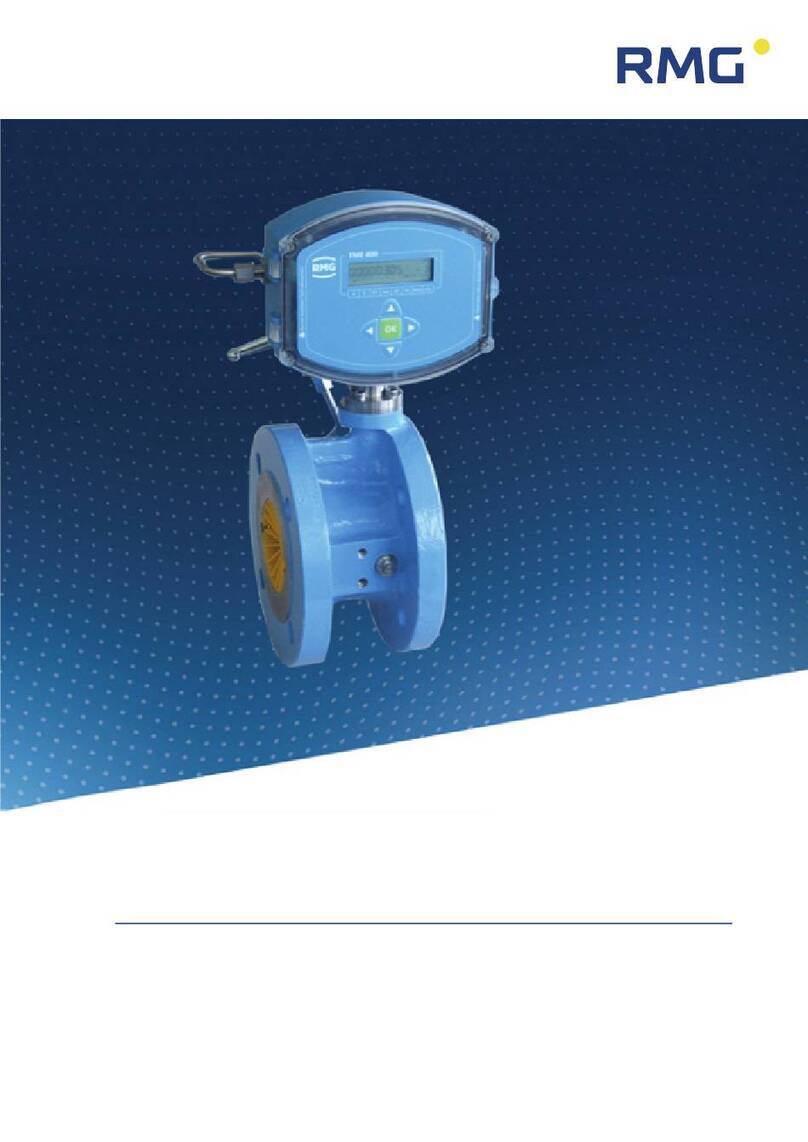

Turbine Meters TRZ 04 / TRZ 04-K

OPERATING INSTRUCTIONS

STATUS February, 1st 2017 Version: 04

CONTENTS

................................................................................................................................................................................................

................................................................................................................................................................................................

Manual TRZ 04 · EN04 · February, 1st 2017

Contents

1INTRODUCTION................................................................1

1.1Objective of the manual ..................................................................1

1.1.1Abbreviations.........................................................................................1

1.1.2Symbols.................................................................................................1

1.1.3Layout of instructions.............................................................................2

1.1.4Using the turbine meter TRZ04 .............................................................3

1.1.5Risk assessment and mitigation............................................................8

1.1.6Validity of the manual ............................................................................9

1.1.7Transportation .....................................................................................11

1.1.8Delivery................................................................................................12

1.1.9Dispose of packaging material ............................................................12

1.1.10Storage.............................................................................................12

1.2Structure of the manual ................................................................13

1.3Overview, Function and Application............................................13

1.4Method of operation ......................................................................16

1.5Approvals.......................................................................................17

1.6Standards / Guidelines..................................................................17

1.7Validity of meter proving...............................................................17

1.8Measuring ranges..........................................................................18

1.8.1Extension of the measuring range.......................................................18

1.9Accuracy of measurement............................................................20

1.10Temperature ranges ...................................................................21

1.11Pressure loss..............................................................................21

1.12Pressure tap................................................................................22

1.13Using gas meters with different types of gases.......................23

1.14Installing the device in the pipeline ..........................................24

2INSTALLATION AND COMMISSIONING........................25

2.1Installation......................................................................................25

2.2Operating data ...............................................................................27

2.2.1Technical Guideline G 13 ....................................................................28

2.2.2Perforated-plate straighteners.............................................................29

2.2.3Seals....................................................................................................30

2.2.4Screws.................................................................................................31

2.3Meter head......................................................................................31

2.4Standard version ...........................................................................32

CONTENTS

................................................................................................................................................................................................

................................................................................................................................................................................................

Manual TRZ 04 · EN04 · February, 1st 2017

2.5Type “G-D” meter head.................................................................33

2.5.1Permissible torques (type “G-D”).........................................................33

2.5.2Mechanical drive shaft coupling ..........................................................35

2.5.3Connection of additional equipment ....................................................35

2.5.4Pulse transmitters................................................................................37

2.5.5Pulse transmitters in the meter head (LF) ...........................................38

2.5.6Pulse transmitters in the measuring element (HF 2-D and HF 3-D)....38

2.5.7Tamper contact....................................................................................38

2.5.8Encoder ...............................................................................................38

2.6Specifications of the pulse transmitters......................................40

2.7Temperature measurement...........................................................41

2.8Commissioning..............................................................................41

2.8.1Filling with oil .......................................................................................41

2.8.2Connecting the gas flow ......................................................................41

3OPERATION....................................................................43

3.1Influences on the error of measurement due to operation ........43

3.1.1Intermittent operation...........................................................................43

3.1.2Influence of pulsations.........................................................................43

3.1.3Consequences.....................................................................................44

3.1.4Limiting values.....................................................................................44

3.2Lubrication.....................................................................................46

3.2.1Lubricator.............................................................................................46

3.2.2Specification for lubricating oils ...........................................................46

3.2.3Initial lubrication...................................................................................47

3.2.4Relubrication........................................................................................47

3.2.5Lubrication procedure..........................................................................48

3.2.6Maintenance........................................................................................49

4LABELLING.....................................................................50

5SPECIFICATIONS ...........................................................52

5.1Meas. ranges/Dimensions/Pressure classes of the TRZ 04.......52

5.2Meas. ranges/Dimensions/Pressure classes of TRZ 04-K.........53

5.3Qmin depending on the operating pressure in natural gas.......53

5.4Values for 2nd metering or meters without MID approval...........54

5.5Overview of the materials used....................................................55

ANNEX.....................................................................................56

Certificate for LF-, HF-sensors and Encoder...............................................56

Connector pin assignments ..........................................................................57

Installation and Commissioning

................................................................................................................................................................................................

................................................................................................................................................................................................

Manual TRZ 04 · EN04 · February, 1st 2017

1

1 Introduction

1.1 Objective of the manual

The manual provides you with the information that is designed for trouble-free and safe

operation.

The TRZ04 is state of the art and conceived and manufactured according to the

recognized safety standards and guidelines. However, risks may arise during use that can

be easily avoided by observing this manual. For this reason, you may only use the device

as intended and in technically sound condition.

Warning

If the ultrasonic gas meter is not used for its intended purpose, warranty claims

will be void.

1.1.1 Abbreviations

The following abbreviations are used:

ca. circa, approximately

as app. as applicable

max. maximum

MC Measurement Canada

MID Measurement Instruments Directive

min. minimum

e.g. for example

1.1.2 Symbols

The following symbols are used:

1, 2, … Marks steps within a work operation

..

Introduction

Installation and Commissioning

................................................................................................................................................................................................

................................................................................................................................................................................................

Manual TRZ 04 · EN04 · February, 1st 2017

2

1.1.3 Layout of instructions

The following instructions are used:

Danger

This warning instruction informs you of potentially hazardous situations that can occur

as a result of incorrect operation or human error. If these situations are not avoided,

they can lead to fatal or severest injuries.

Warning

This warning instruction informs you of possible hazardous situations that can occur

as a result of incorrect operation or human error. If these situations are not avoided,

they can lead to fatal or severe injuries.

Caution

This warning instruction informs you of possible hazardous situations that can

occur as a result of incorrect operation or human error. If these situations are

not avoided, they can lead to slight or minor injuries.

Notice

This warning instruction informs you of potentially hazardous situations that

can occur as a result of incorrect operation or human error. If these situations

are not avoided, they can result in material damage to the device or the vicinity.

This notice may also give to you tips on how to simplify your work. With this

screen, you additionally receive further information on the device or the work

process.

Introduction

Installation and Commissioning

................................................................................................................................................................................................

................................................................................................................................................................................................

Manual TRZ 04 · EN04 · February, 1st 2017

3

1.1.4 Using the turbine meter TRZ04

1.1.4.1 Safety instructions

Danger

Observe the following safety instructions !!

Non-observance of these safety instructions can lead to a risk of life and limb

and health of the person as well as damage to the environment or property

damage.

Note that the safety instructions in this operating instruction and on the device cannot

cover all possible hazardous situations as the combination of different circumstances is

impossible to predict. To simply follow the instructions specified may not normally be

sufficient enough to ensure for correct operation. Always be observant and also consider

the following:

Before working with the device for the first time, read through this operating

instruction and, in particular, follow the safety instructions carefully.

The operating instruction warns against the residual risks for users, third parties,

devices or other material assets. The safety instructions used refer to residual risks

that cannot be avoided due to the design.

Operate the device only in a sound state and when observing the operating

instruction.

Also observe the local legal accident prevention, installation and assembly

guidelines.

Notice

Always keep the operating instructions within reach for use at the place of

installation.

For safe operation, the safety instructions must be observed and followed.

The manufacturer is not responsible for any damage that result as a

consequence of not observing the operating instruction.

Introduction

Installation and Commissioning

................................................................................................................................................................................................

................................................................................................................................................................................................

Manual TRZ 04 · EN04 · February, 1st 2017

4

Danger

Service and maintenance work or repairs that are not described in the

operating instruction must not be carried out without previous consultation

with the manufacturer.

Changes to the device are forbidden.

For safe operation, the technical specifications must be observed and followed.

Performance limits must not be exceeded (chapter 5 Specifications).

For a safe operation, the device must only be used in the scope of its intended

use.

Only use the listed set screws, bolts, nuts and gaskets or parts with similar

characteristics for the installation of the meter in the pipeline (chapter 1.14

Installing the device in the pipeline)

The device should only be used under the intended use for safe operation

(Chapter 1.3 Overview, Function and Application)

1.1.4.2 Hazards during commissioning

Initial start up Initial start-up must only be carried out by especially

trained personal (training by RMG) or by service personal

from RMG.

Notice

After the initial start-up an inspection report shall be drawn up. This, the

operation manual and CE declaration of conformity must always be accessible.

As far as possible all the sharp edges have been eliminated on the device.

Nevertheless, when working on the personal protective equipment must be

used, which must provide the operator.

Introduction

Installation and Commissioning

................................................................................................................................................................................................

................................................................................................................................................................................................

Manual TRZ 04 · EN04 · February, 1st 2017

5

Danger

Install the device TRZ04 in accordance with operating instructions. If the TRZ04

is not installed according to the manual, there is possibly an insufficient

explosion protection.

The explosion protection expires !!

Please take care during the installation to the flow direction marked on the

housing by an arrow.

When staff carry out work without sufficient qualification, risks remain

understated when working. Explosion or fire may happen. Perform the work

only if you have the appropriate qualifications and you are an expert.

If you do not use the appropriate tools and materials, components may be

damaged. Use tools that are recommended to you for the job in the operating

instructions.

Mechanical installation Mechanical installation must only be carried out by the

respectively qualified specialist personnel.

Electrical installation Installation on components must only be carried out by

qualified electricians.

Mechanical and/or

electrical installation

The specialist personnel require a training especially for

working in potentially explosive environment. Specialist

personnel are persons that can verify a training / further

education according to DIN VDE 0105, IEC 364 or a

similar national standards.

Introduction

Installation and Commissioning

................................................................................................................................................................................................

................................................................................................................................................................................................

Manual TRZ 04 · EN04 · February, 1st 2017

6

Danger

The installation and removal of the TRZ04 or to the TRZ04 connected

convertor may only be carried out in an explosion-free, de-pressurized

atmosphere. It is important to pay attention to the descriptions of the

operation manual during the installation process.

It is generally recommended to ask the RMG Service for any installation or

removal.

After working on pressurized components, a control of leaks must be carried

out.

All points above have to be considered for any repair and maintenance and

in general, when an opening of the meter (convertor) is required.

Parts to lock the flanges, locking screws, fittings and check valves, oil

supply and the pressure tap fittings, valves, HF pulse device, protecting pipe

and rotating adapter may not be opened during operation.

1.1.4.3 Danger when using, servicing and maintaining the device TRZ04

Operating personnel The operating personnel are to use and operate the

device within the scope of the intended purpose.

Maintenance personnel Work on the device must only be carried out by specialist

personnel that can carry out the respective work assigned

to them as a result of their training, knowledge and

experience as well as the applicable regulations. These

specialist personnel are familiar with the legal guidelines

for accident prevention and can evaluate and avoid

possible risks by themselves.

Maintaining and cleaning Maintenance and cleaning must only be carried out by the

respectively qualified specialist personnel.

Danger

If staff carry out work without sufficient qualification, risks may be

underestimated when working. Explosion or fire may happen. If work is

carried out in hazardous areas on voltage supporting equipment, resulting

sparks may cause an explosion.

Introduction

Installation and Commissioning

................................................................................................................................................................................................

................................................................................................................................................................................................

Manual TRZ 04 · EN04 · February, 1st 2017

7

Danger

If the unit is not cleaned in accordance with the operating instructions, the

device may be damaged. Clean the unit only in accordance with the operating

instructions.

When not using appropriate tools, components can be damaged. The explosion

protection expires.

- Clean with a damp cloth!

Danger

The TRZ04 may only be used as intended !!

(Chapter 1.3 Overview, Function and Application).

Avoid any use of the TRZ04 as possible climbing aid or attachments of TRZ04

as possible handholds !!

1.1.4.4 Specialized knowledge required

Notice

Persons working with or on the device must have the following knowledge:

Training / education for working in potentially explosive environments

The ability to correctly assess dangers and risks when using the device.

Possible dangers are, e.g., components under pressure or the result of

incorrect installation.

Recognize dangers that could be caused by the used flow medium.

Training / education by RMG for working with gas measuring instruments.

Education / instruction in all country-specific standards and directives to be

observed for work that is to be carried out on the device.

Introduction

Installation and Commissioning

................................................................................................................................................................................................

................................................................................................................................................................................................

Manual TRZ 04 · EN04 · February, 1st 2017

8

1.1.5 Risk assessment and mitigation

The TRZ04 subjects to risks in its use, which were judged by qualified staff of the company

RMG. Risks may arise due to high pressures, more rarely by too low. Even work outside

the permissible temperature range can lead to danger. Invalid current and voltage values

can trigger explosions in hazardous areas.

The risk assessment assumes that when installing or removing a turbine a draining and

venting of the pipeline takes place. Thus, and only then no explosive gas mixture is in the

pipeline.

Of course (chapter 1.1.4.4 Specialized knowledge required) only work by trained

personnel are permitted, which is also trained to know proper tools and use only this.

These risks have been considered during the development phase and action were taken to

minimize these risks.

Risk mitigation measures:

- All pressurized parts are designed in accordance to AD 2000 regulations, PED

Annex 1

- The complete design being pressurized is verified by the TÜV Hessen

- All pressurized parts are made with material certificate; there is a traceability to the

batch tracking of all pressurized parts

- The mechanical properties of all relevant pressurized components are checked by

tensile testing, impact testing and hardness testing

- In addition, non-destructive testing were applied: X-ray and ultrasonic testing of the

meter housing for defects in material, surface crack detection by magnetic particle

and dye-penetration

- With pressure tests 1.5 times of the intended operating pressure the strength of the

components were verified; leak test were carried out at 1.1 times of the intended

operating pressure. Successful tests were marked

- The maximum operating pressure is stated on the nameplate of the device, as well

as the temperature range. Operation of the device is only permitted within the

indicated ranges.

Introduction

Installation and Commissioning

................................................................................................................................................................................................

................................................................................................................................................................................................

Manual TRZ 04 · EN04 · February, 1st 2017

9

Danger

For any work in an explosive atmosphere (all areas):

- The pulse output of the turbine meter has to be connected to

intrinsically safe circuits, only.

- For maintenance and repair work only tool must be used, which is

approved for Ex zone. 1

- Otherwise, work must be carried out only if there is no explosive

atmosphere

- Danger of ignition caused by impact or friction must be avoided.

- In hazardous areas, the wiring / installation must be performed by

trained personnel in accordance to EN 60079-14 and according to

national regulations

- Skilled persons are in accordance to DIN VDE 0105 or IEC 364, or

comparable standards

- Use only trained and qualified personnel. Work on the measuring

system may only be carried out by qualified personnel and must be

checked by a specialist supervisor.

- Qualified persons are able to carry out such work. Qualification is

valid due to their training, experience or through instruction and their

knowledge of relevant standards, regulations, accident prevention

regulations and plant conditions for the safety of people. It is essential

that these people are able to recognize and avoid possible dangers.

1.1.6 Validity of the manual

This manual describes the turbine meter TRZ04. The TRZ04 is only a part of a complete

on site system. Observe also the instructions of other components of the site system. If

you find contradicting instructions, please contact RMG.

Notice

Make sure that the performance of the power connector corresponds to the

data on the nameplate. Additionally observe any existing national

regulations in the country. Use cable suitable for the cable glands.

Introduction

Installation and Commissioning

................................................................................................................................................................................................

................................................................................................................................................................................................

Manual TRZ 04 · EN04 · February, 1st 2017

10

Danger

Perform the work only if you have the appropriate qualifications and you are a

trained specialist.

1.1.6.1 Hazards during Operation

Please take care of the information provided by the plant manufacturer and/or plant

manager.

1.1.6.2 Danger during operation in hazardous areas

Operate the device in perfect and complete condition.

When you perform technical modifications to the instrument, a safe operation can no

longer be guaranteed.

Danger

Use the device only in the original condition. The TRZ04 may be operated in

explosion zone 1, but only within the permitted temperatures (Chapter 1.10

Temperature ranges)

1.1.6.3 Operator responsibility

Take care as plant manager that only sufficiently skilled personnel will work on the device.

Ensure that all employees who handle the equipment have read and understood these

instructions. Additionally, you are obliged to train staff on a regular basis and to inform

them about any dangers. Ensure that any work carried out on the device is done by

qualified personnel and checked by responsible specialists. You must establish clearly the

responsibilities for installation, operation, troubleshooting, maintenance and cleaning.

Point out to your staff any risks involved when using the device.

Introduction

Installation and Commissioning

................................................................................................................................................................................................

................................................................................................................................................................................................

Manual TRZ 04 · EN04 · February, 1st 2017

11

1.1.7 Transportation

The device is packaged customized according to the transport requirements.

Warning

Risk of injury during transport

Any foot screws must be fitted, if they are used as transit protection against

rolling and tipping.

Take additional care that a rolling and tilting is safely prevented.

To lift the meter only the special lifting eyes / eye bolts may be used.

Pay attention to the maximal loads for the lifting devices (chapter 5

Specifications) – don’t exceed those.

Make sure that the load is fastened securely before lifting.

Do not stand under lifted loads.

During lifting and/or depositing the device may slip, tip over or fall.

Disregarding the maximum load capacity of the lifting device, the device may

fall down. For any people standing nearby, there is a significant risk of serious

injury.

If the unit is supplied on a Euro pallet, the unit can be transported using a lift

truck or a forklift.

During the transport the meter has to be protected against shock or vibration.

The meter or its additionally mounted spool pieces are equipped with flanges

that are protected with a sticker foil or blind plugs made of plastic. These must

be removed completely before installation in the pipeline. Remaining rests of

these protections may change the flow pattern and may result in a

measurement error !!

For any transport e.g. for recalibration we ask you to use these protections.

Introduction

Installation and Commissioning

................................................................................................................................................................................................

................................................................................................................................................................................................

Manual TRZ 04 · EN04 · February, 1st 2017

12

1.1.8 Delivery

Supplied number of parts may differ depending on the optional customer order. "Usually"

is following in the delivery:

Part Quantity

Turbine meter TRZ04 1

1 small bottle of oil for lubrication 1

Manual 1

Test report 1

Calibration certificate 1

Material test report 1

Certificate strength 3.1 .. optional

… …

1.1.9 Dispose of packaging material

Dispose the packing material in an environmentally friendly way in accordance to the

national standards.

1.1.10 Storage

Avoid long periods of storage. Check the device after any storage for damage and

functionality. Ask for a check from the RMG service after a storage period for the device of

over one year. In this case please send the device to RMG.

Notice

For storage, a dry and protected space has to be provided.

It is important to ensure that all open pipe pieces must be sealed.

Introduction

Installation and Commissioning

................................................................................................................................................................................................

................................................................................................................................................................................................

Manual TRZ 04 · EN04 · February, 1st 2017

13

1.2 Structure of the manual

The introduction of this manual contains two parts. In the first part general guidelines are

listed; the symbols used and structure of advices are given, but also issued is a risk

assessment. In addition, it contains guidelines for the transport and storage of the TRZ04.

The second part introduces the operation of TRZ04; there are basic standards listed;

pressure and temperature ranges are given limiting the use of the TRZ04.

The second chapter describes the use of TRZ04. It explains how a high accuracy can be

achieved, how data can be received by the encoder and tapped there. The third chapter

provides recommendations on how the current operation can be ensured. These include

the accuracy influencing flow disturbances as well as regular lubrication of the bearings of

the turbine meter.

The fourth chapter describes the marking of the TRZ04 and in the fifth the technical data of

TRZ04 are summarized. The appendix includes details to the previous chapters, a

summary of certificates and approvals.

1.3 Overview, Function and Application

The TRZ 04 and TRZ 04-K are used to measure volume flow rates of non-aggressive

gases and fuel gases, especially natural gas. Measurement of corrosive gases is only

possible with special designs. The measurement of liquids is not possible and will destroy

the device.

The TRZ 04 is a flow rate meter, which can be used for custody transfer flow rate

measurement. The TRZ 04 K, however, can only be used for operational volume flow rate

measurements. Both types measure the gas quantity, means the volume flowing through

the unit at the actual pressure and temperature. Both determine the volume flow rate at the

actual conditions. The volume flow rate of the gas flowing through the meter is indicated by

a mechanical totalizer operating in m³.

In addition, the turbine can be equipped to supply high or low frequency pulses and reed

contacts can be fitted, too. The measured number of pulses are proportional to the volume

that has passed the meter. These pulses can be further processed by volume correctors or

remote totalizers.

The most important differences between the versions TRZ 04 und TRZ 04-K are:

TRZ 04

Approved for custody transfer metering

Installation length: 3 x DN

Introduction

Installation and Commissioning

................................................................................................................................................................................................

................................................................................................................................................................................................

Manual TRZ 04 · EN04 · February, 1st 2017

14

Accuracy 0.5% (above 0.2 Qmax)

Blade monitoring system

TRZ 04-K

For secondary metering.

Installation length: 1.5 x DN (DN 50: 3 DN)

Accuracy 1% (above 0.2 Qmax)

The following applies to all meter types:

Maximum operating pressure: 100 bar (not for gas meters with a plastic turbine wheel)

Meter sizes from G 65 to G 1600

Measuring range 1:20 at operating pressure p

m

= 1 barg;

Measuring range up to 1:100 at p

m

>= 3 barg (see table: Q

min

depending on p

min

)

Connections in compliance with DIN or ANSI are available

Special designs for aggressive gases are available

Available for low temperatures (< - 20°C)

All gas meters can be operated in any position up to the nominal diameter of

DN 200.

Notice

The meters with nominal diameters from DN 50 to DN 200 are approved

for custody transfer metering (up to G 1600).

The nominal diameters from DN 250 are special versions without MID

approval for which RMG does not guarantee the availability (only on

request).

The TRZ 04 and TRZ 04-K are approved for the use in explosive areas; the indication is:

II 1G Ex ia IIC T4 (HF-Sensors)

II 2G Ex ib IIC T6 (Encoder)

The corresponding conformity certificates can be found in the appendix.

Introduction

Installation and Commissioning

................................................................................................................................................................................................

................................................................................................................................................................................................

Manual TRZ 04 · EN04 · February, 1st 2017

15

Danger

To operation the encoder you have to care of:

The encoder must be mounted and removed by a qualified electrician, as

sensitive electronic circuits are part of the encoder.

Attention: Risk of destruction due to static electric discharge, for example

caused by the friction of clothing.

Do not change anything at the encoder, otherwise the approvals and certificate

lose their validity.

Information about temperature limits are given in chapter 1.10 Temperature ranges.

The TRZ04 meets the standards, guidelines and regulations:

Chapter 1.6 Standards / Guidelines and the appendix

These technical limitations you must comply with the TRZ04 for safe operation:

Chapter 5 Specifications

The device may only be operated with the following types of gases. Only with these stated

gases a safe operation is ensured:

•

Gases of class 1

•

Gases of class 2

•

Gases of class 3

The friction of the gas components must be within the limits in accordance with the

EN 437: 2009 are for test gases.

The following instructions must be observed:

Notice

The RMG TRZ 04 and TRZ 04-K can be operated in any mounting orientation up

to DN200, from the DN 250 is a horizontal orientation is required.

If a mounting orientation is specified when ordering, the meter has to be

installed in this orientation.

It is also important to ensure that the filling port of the lubricator faces upwards.

Introduction

Installation and Commissioning

................................................................................................................................................................................................

................................................................................................................................................................................................

Manual TRZ 04 · EN04 · February, 1st 2017

16

1.4 Method of operation

The method of operation of the mechanical turbine meter is based on the measurement of

the gas velocity. The velocity of the gas flowing through the gas meter is increased in the

flow straightener and the gas strikes the turbine wheel in a defined flow cross section. In

the flow straightener, unwanted vortices, turbulences and asymmetries are removed or

reduced. The turbine wheel is mounted axially, while the blades of the turbine wheel are

arranged at a certain angle to the gas flow. Within the measuring range (Qmin - Qmax),

the rotational speed of the turbine wheel is almost proportional to the mean gas velocity

and, therefore, to the rate of flow. The number of rotations is a measure of the volume that

has flowed through. The rotary movement of the turbine wheel is transmitted by a

magnetic coupling to the unpressurized meter head. Downstream of the coupling, there is

a gearing which reduces the rotational speed of the turbine wheel to match the mechanical

totalizer. Two LF pulse transmitters (reed contacts) and a tamper contact are located on

the totalizer.

Figure 1: Sectional drawing of a turbine meter.

Downstream of the turbine wheel, a cam wheel (reference wheel) is located on the same

shaft. Two HF sensors (proximity switches) generate a signal if a blade of the turbine

wheel (HF 3-D) or a cam of the reference wheel (HF 2-D) passes them. In this way, two

pulse sequences are generated which are out of phase. The generated pulses can be

further processed for secondary volume measurements or flow measurements.

Flow

straightener

Meter head with

mechanical index,

Encoder and LF

pulse transmitters

Turbine

wheel

Reference

wheel

HF pulse

transmitters

Introduction

Installation and Commissioning

................................................................................................................................................................................................

................................................................................................................................................................................................

Manual TRZ 04 · EN04 · February, 1st 2017

17

1.5 Approvals

Type TRZ 04 has been approved for custody transfer metering.

The following approvals have been obtained:

MID approval No. T10417

PED approval No. CE 0091

Independent whether the turbine meter can be remotely read (via the encoder) it is fitted

with a metrological controlled mechanical index. The reading of this index is the

measurement result that serves as the basis for billing.

Type TRZ 04-K has not been approved for custody transfer metering. The following

approvals have been obtained:

PED 2014/68/EU / DGRL2014/68/EU ISG-22-12-1980 (TRZ04)

ISG-22-12-1994 (TRZ04-K)

1.6 Standards / Guidelines

All RMG turbine meters have passed the disturbance measurements in compliance with

OIML Recommendation IR-32/89, Annex A, with slight and heavy flow disturbances.

Therefore, this meter design meets the requirements for installation in compliance with

Technical Guideline G13, Sec. 1. Test specifications are as laid down in PTB Testing

Instructions, Vol. 4, Volume gas meters, 2nd revised edition of 1992.

The RMG turbine meters of type TRZ 04 comply with EN 12261 and the European

Measuring Instrument Directive 2004/22/EG (MID).

1.7 Validity of meter proving

The turbine meters of type TRZ 04 which are suitable for custody transfer metering must

be subjected to subsequent meter proving at regular intervals. The validity of meter

proving is determined in the German Metering and Calibration Rules (MessEV, Edition 11,

December 2014) with the following periods:

Turbine meters without lubricator 8 years

Turbine meters with flow range 65 m3/h to 4.000 m3/h 12 years

Turbine meters with flow range > 4.000 m3/h to < 16.000 m3/h 16 years

Turbine meters with flow range 16.000 m3/h unlimited

Introduction

This manual suits for next models

1

Table of contents

Other RMG Measuring Instrument manuals