Document: LT0712 QE20 Installation Manual

Issue 1.0 13 June 2023 Page iii

TABLE OF CONTENTS

1. Introduction .................................................................................................... 1-1

1.1 Introduction and Scope....................................................................................................1-1

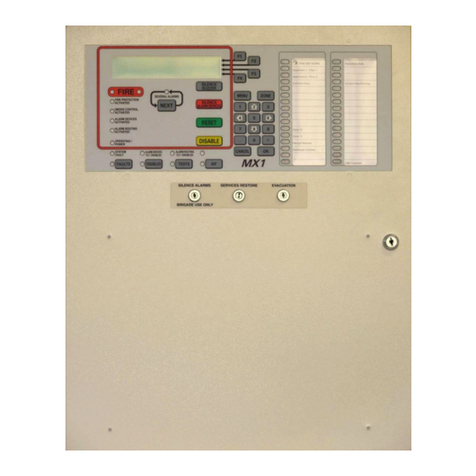

1.2 Description of QE20 .........................................................................................................1-1

1.3 Specifications – QE20 Panel............................................................................................1-5

1.4 Other QE20 & Product Manuals ......................................................................................1-6

1.4.1 VIGILANT QE20 Manuals ..............................................................................................1-6

1.4.2 Other VIGILANT Manuals ..............................................................................................1-7

1.4.3 Third Party Manuals .......................................................................................................1-7

2. Cabinet Installation & Wiring ........................................................................ 2-1

2.1 QE20 Cabinets ..................................................................................................................2-1

2.2 Handling & Checking Cabinets .......................................................................................2-1

2.3 Cabinet Installation...........................................................................................................2-2

2.3.1 Requirements of Cabinet Location.................................................................................2-2

2.3.2 Fixing Cabinet to Wall ....................................................................................................2-2

2.3.3 Removal and Refitting of Internal Mounting Frames......................................................2-4

2.3.4 Changing Outer Door Hinge Side...................................................................................2-4

2.4 Mains Wiring .....................................................................................................................2-4

2.4.1 Mains Feed.....................................................................................................................2-4

2.4.2 Turning PSE On and Off ................................................................................................2-5

2.5 PSE Interconnection Wiring ............................................................................................2-5

2.6 Battery Installation & Wiring............................................................................................2-6

2.6.1 Battery Fitting and Wiring ...............................................................................................2-6

2.6.2 Battery Connection and Disconnection ..........................................................................2-6

2.7 Internal 24V DC Distribution ............................................................................................2-7

2.8 Adjacent Cabinet Wiring ..................................................................................................2-7

2.9 Field Wiring .......................................................................................................................2-8

2.10 Remote Cabinet Wiring ....................................................................................................2-8

2.11 Interfacing to Other Systems ..........................................................................................2-8

2.12 Zone, WIP and User Button Labels.................................................................................2-9

3. Site Configuration .......................................................................................... 3-1

3.1 Site Configuration.............................................................................................................3-1

3.2 Example Site Configuration.............................................................................................3-1

3.3 Circuit Usage Report ........................................................................................................3-2

4. On-Site Programming .................................................................................... 4-1

4.1 What’s Available ...............................................................................................................4-1

5. Placing Into Operation................................................................................... 5-1

5.1 Initial Power Up.................................................................................................................5-1

5.2 Check Field Wiring Before Connecting to QE20 ...........................................................5-1