DESCRIPTION:

PROJECT: TAG:

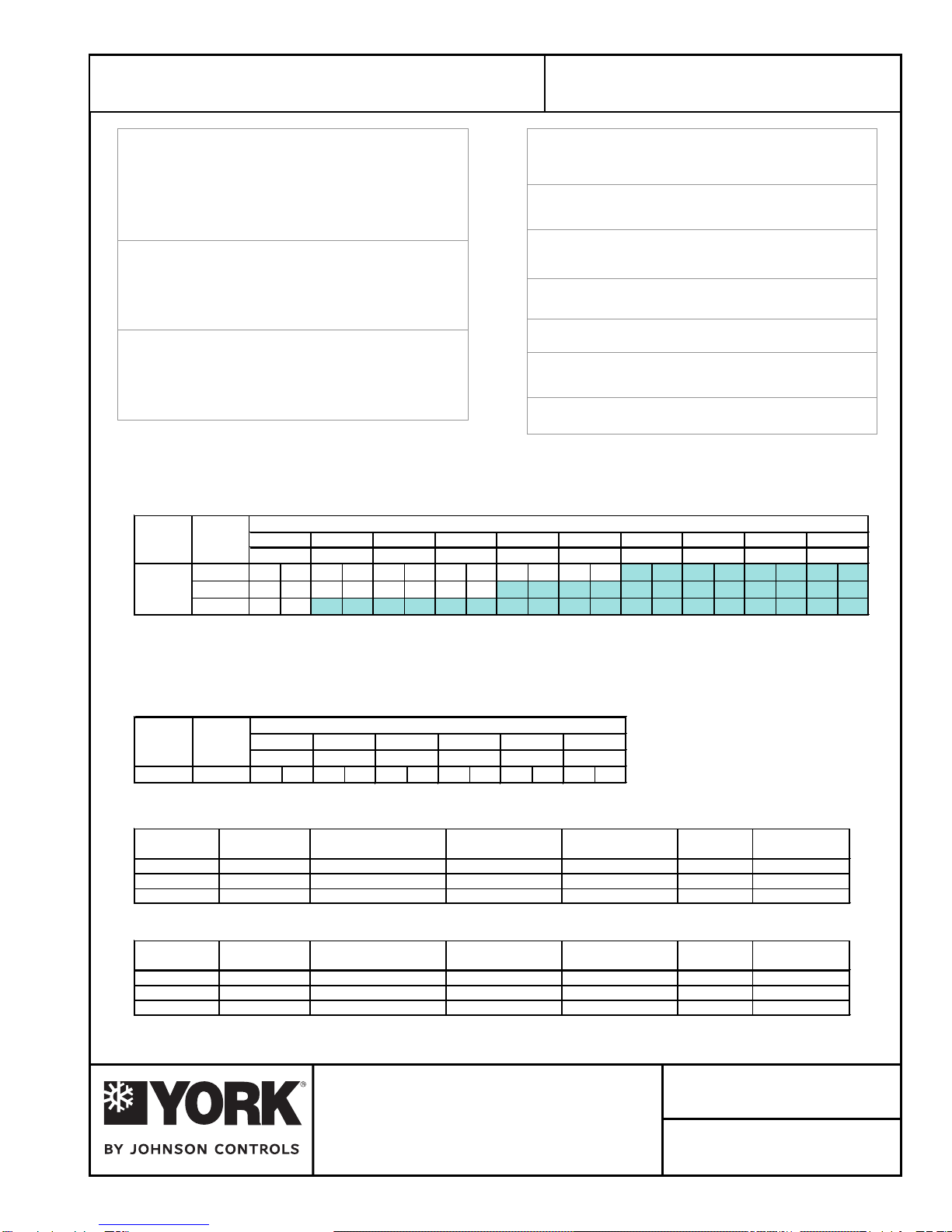

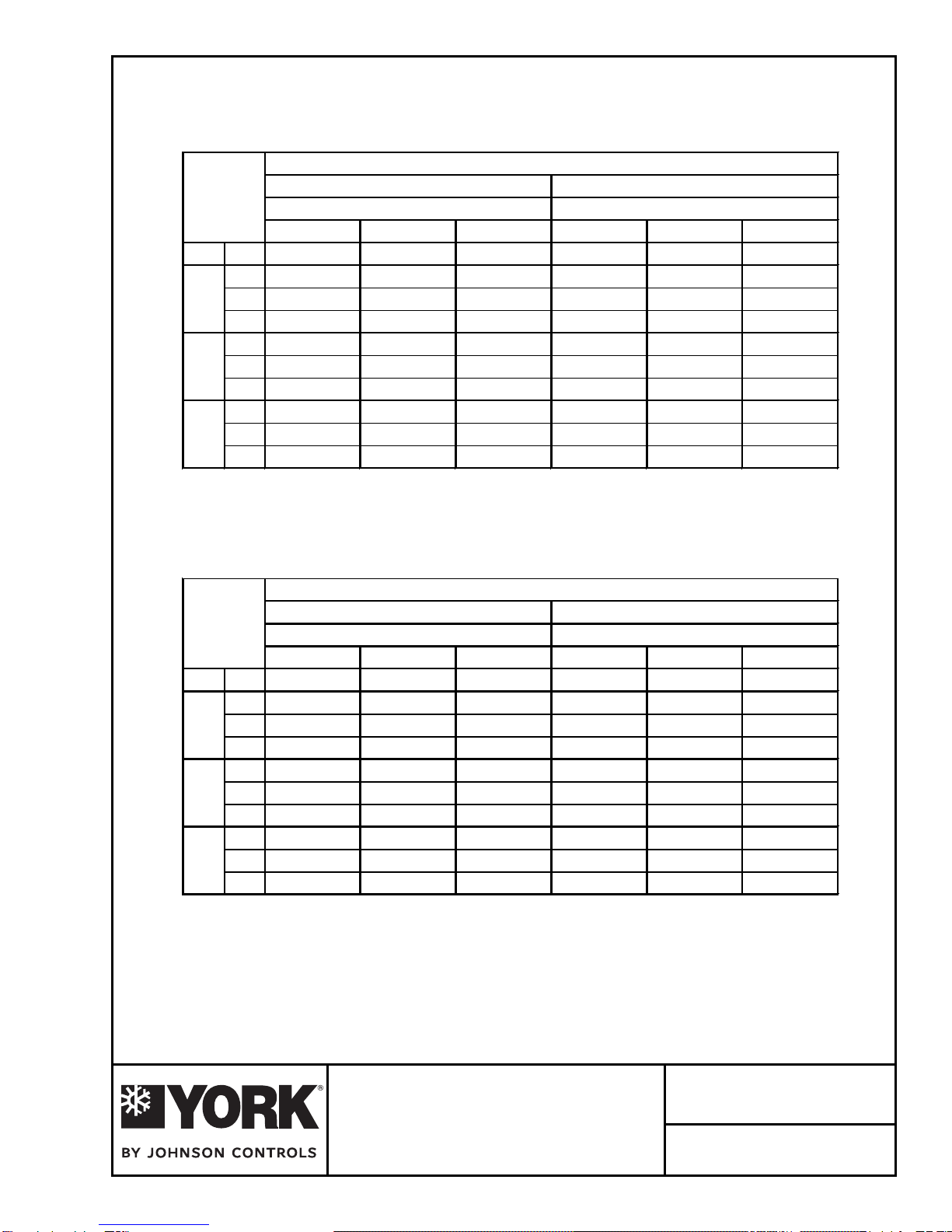

Gross Cooling Capacity [Btuh]:95,000*

Design CFM: 3,200

Energy Efficiency Ratio:11.55 EER**

Net Cooling Capacity [Btuh]: 92,000**

Net Cooling CFM: 3,200

Refrigerant: R22

Charge: 8.75 Lbs./ circuit

Compressor No./Type: 2/Scroll

Refrigerant Circuits: 2 / Independent

Evaporator Coil Face Area: 8.67 [sq ft]

Rows/FPI : 3/10

Refrigerant Control: TX Valve

Filters - Qty./Size: 4/14x25x2

Condenser Coil Face Area: 12.28 [sq ft]

Rows/FPI: 4/14

Evaporator Fan No./Type: 1/CENTRIFUGAL

Diameter x Width [in]:12x15

Drive: Adjustable Belt

Motor HP : 1.5 / 2.0

[Standard/Oversized]

Condenser Fan No./Type: 2/CENTRIFUGAL

Diameter x Width [in]:12x11

Drive: tleBelbatsujdA

Motor HP : 2.0

[Standard]

Operating Weight [lbs.]: 1005

Shipping Weight [lbs.]:1060

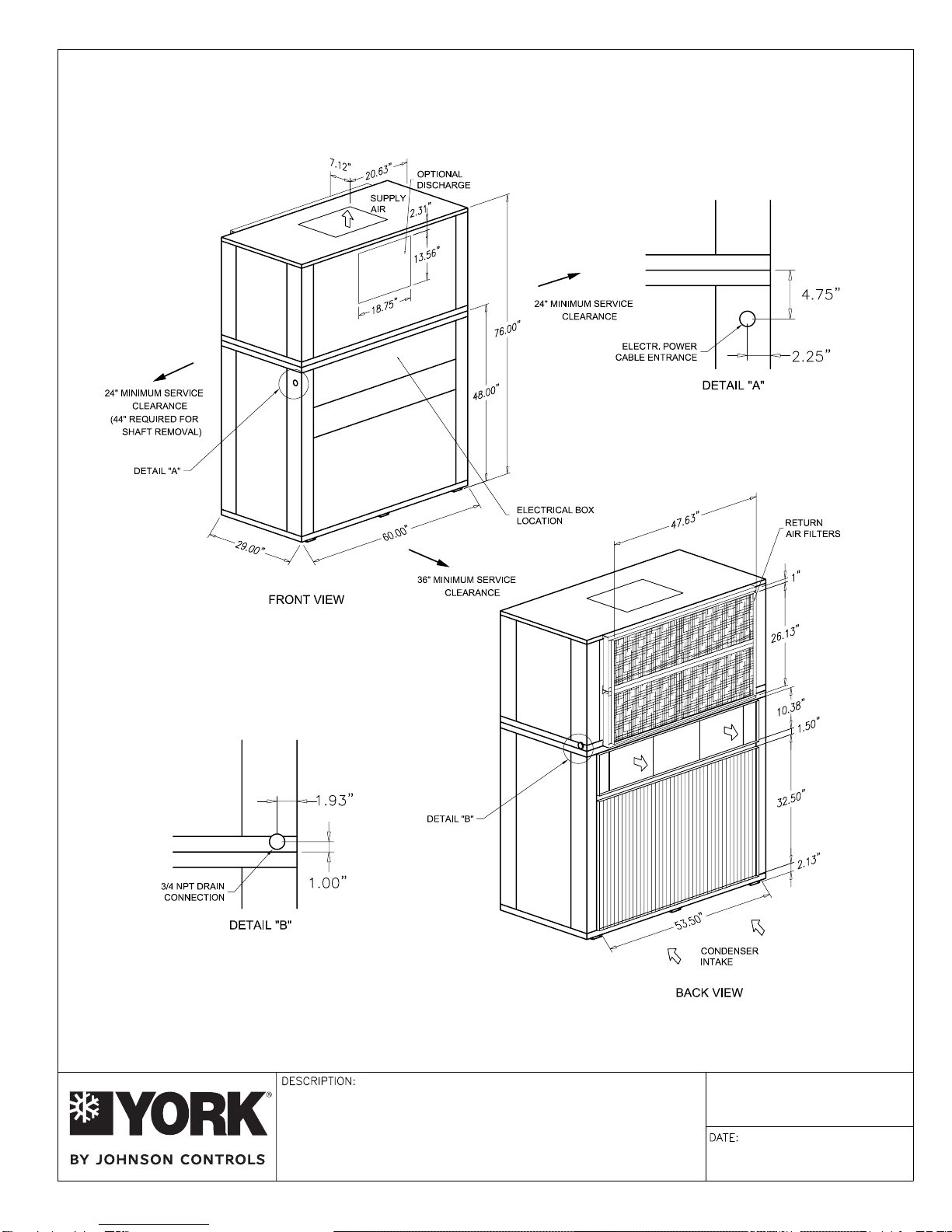

Condensate Connection: 3 / 4 NPT

*Cooling performance is rated at 95

°

F ambient, 80

°

F entering dry bulb, 67

°

F wet bulb

and CFM listed. Gross capacity does not include the effect of fan motor heat.

**Rated in accordance with ARI Standard 360-2000

NOTE:

1. At high evaporator air flows, and wet bulb conditions, condensate carry-over may occur. Adjust airflow downward as necessary.

2. Values include pressure drop from wet coil and clean filters.

3. Shaded areas indicate oversize motors.

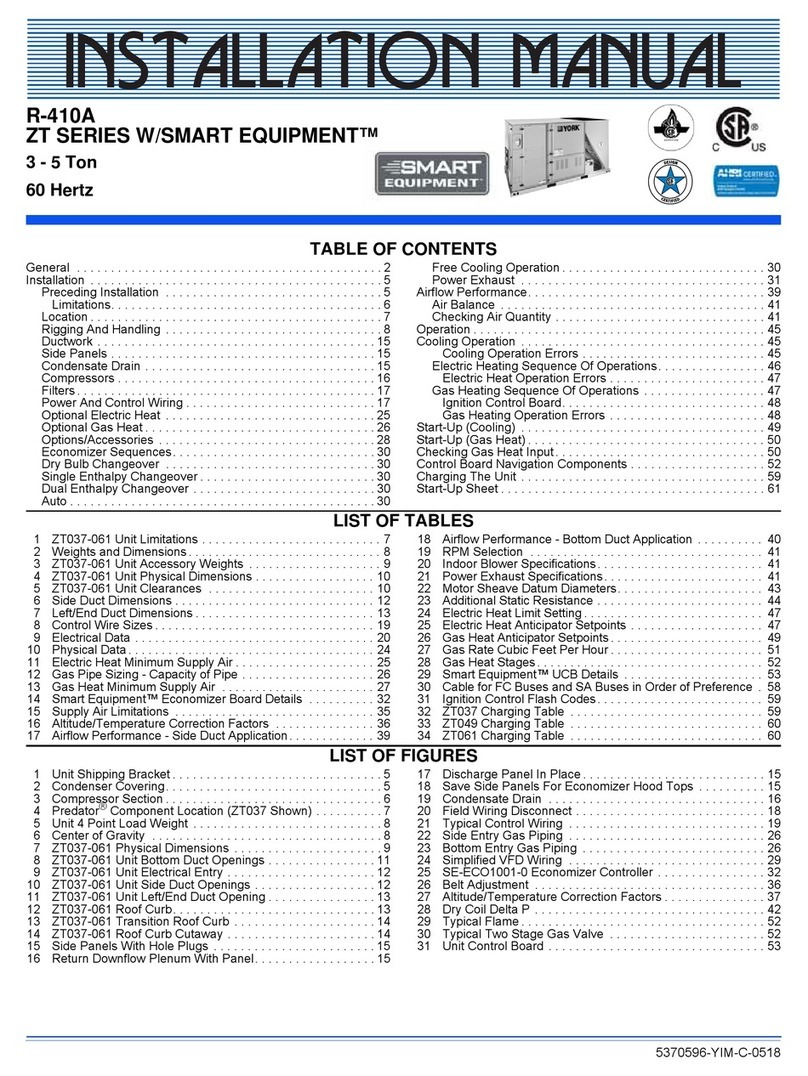

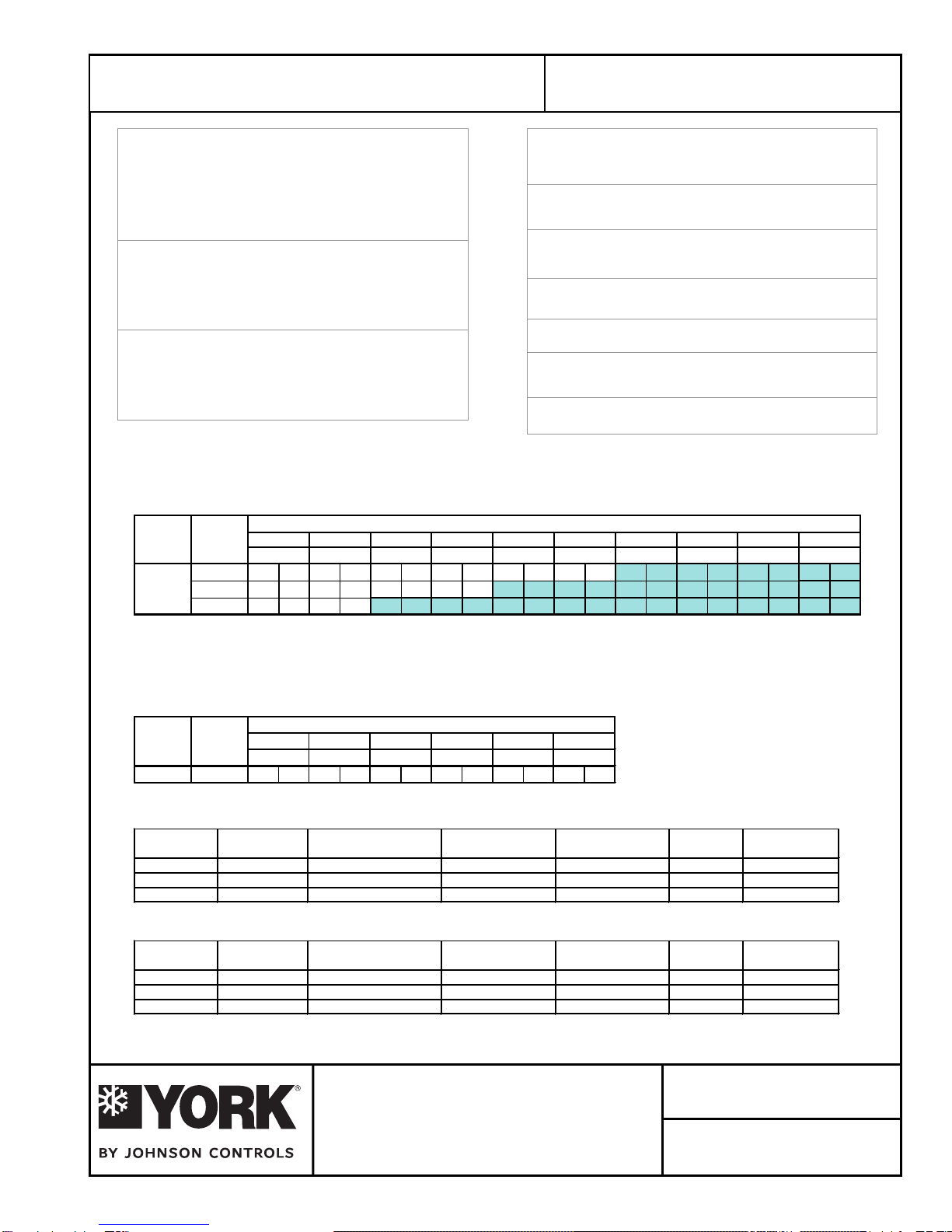

EVAPORATOR FAN PERFORMANCE

CONDENSER FAN PERFORMANCE

ELECTRICAL DATA – STANDARD MOTOR

ELECTRICAL DATA – OVERSIZED MOTOR

MODEL SUPPLY 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

# CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

3000

3200DPV096

DPV096

DPV096

DPV096

DPV096

DPV096

DPV096

DPV096

734 0.76 809 0.89 881 1.02 950 1.17 1016 1.32 1079 1.47 1139 1.63 1196 1.79 1251 1.97 1303 2.17

771 0.90 843 1.03 911 1.17 977 1.32 1040 1.47 1101 1.63 1159 1.81 1214 2.01 ----

3400 811 1.06 879 1.20 944 1.35 1007 1.50 1068 1.66 1128 1.83 1187 2.01 - - ----

EXTERNAL STATIC PRESSURE - Inches W.C.

EXTERNAL STATIC PRESSURE - Inches W.C.

MODEL OUTDOOR 0.2 0.4 0.6 0.8 1.0 1.2

# CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

737 1.19 811 1.38 882 1.59 951 1.82 1017 2.07 - -

MODEL VOLTAGE COMPRESSOR EVAPORATOR FAN CONDENSER FAN MIN. CCT. MAX FUSE /

#QTY RLA LRA HP FLA HP FLA AMPACITY CCT. BKR. AMP

208-230/3/60 2 @ 13.9 88.0 1.50 4.5 2.00 5.9 41.68 50

460/3/60 2 @ 7.1 44.0 1.50 2.1 2.00 2.8 20.97 25

575/3/60 2 @ 5.4 34.0 1.50 1.7 2.00 2.2 15.94 20

MODEL VOLTAGE COMPRESSOR EVAPORATOR FAN CONDENSER FAN MIN. CCT. MAX FUSE /

#QTY RLA LRA HP FLA HP FLA AMPACITY CCT. BKR. AMP

208-230/3/60 2 @ 13.9 88.0

2.00 5.9 2.00 5.9 43.08 50

460/3/60 2 @ 7.1 44.0

2.00 2.8 2.00 2.8 21.67 25

575/3/60 2 @ 5.4 34.0

2.00 2.2 2.00 2.2 16.44 20

4700

March 2008

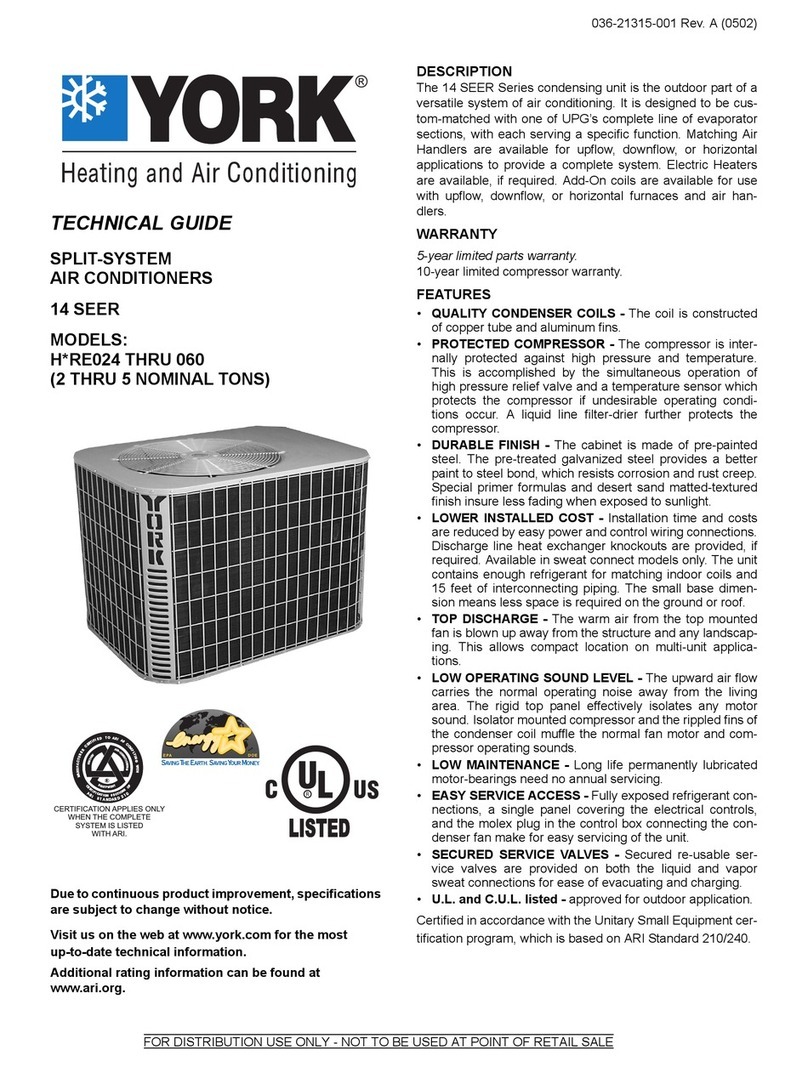

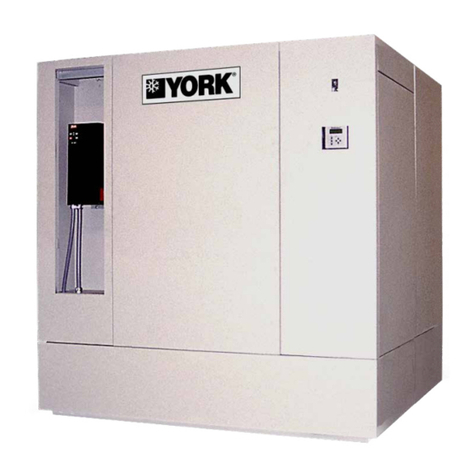

DPV096 VERTICAL UNIT

AIR-COOLED SELF-CONTAINED

Form YK145.12-PA4 (308)

1 of 4

Johnson Controls maintains a continuous product improvement policy, therefore specifications are subject to change without notice.