FORM 201.24-EG1

7

YORK INTERNATIONAL

ALTERNATIVE REFRIGERANTS- Contact yournearestYORK of-

ficeforinformationandavailabilityonalternativeHFCrefrigerants.

ELECTRICALOPTIONS:

MULTIPLEPOINT POWERSUPPLYCONNECTION-

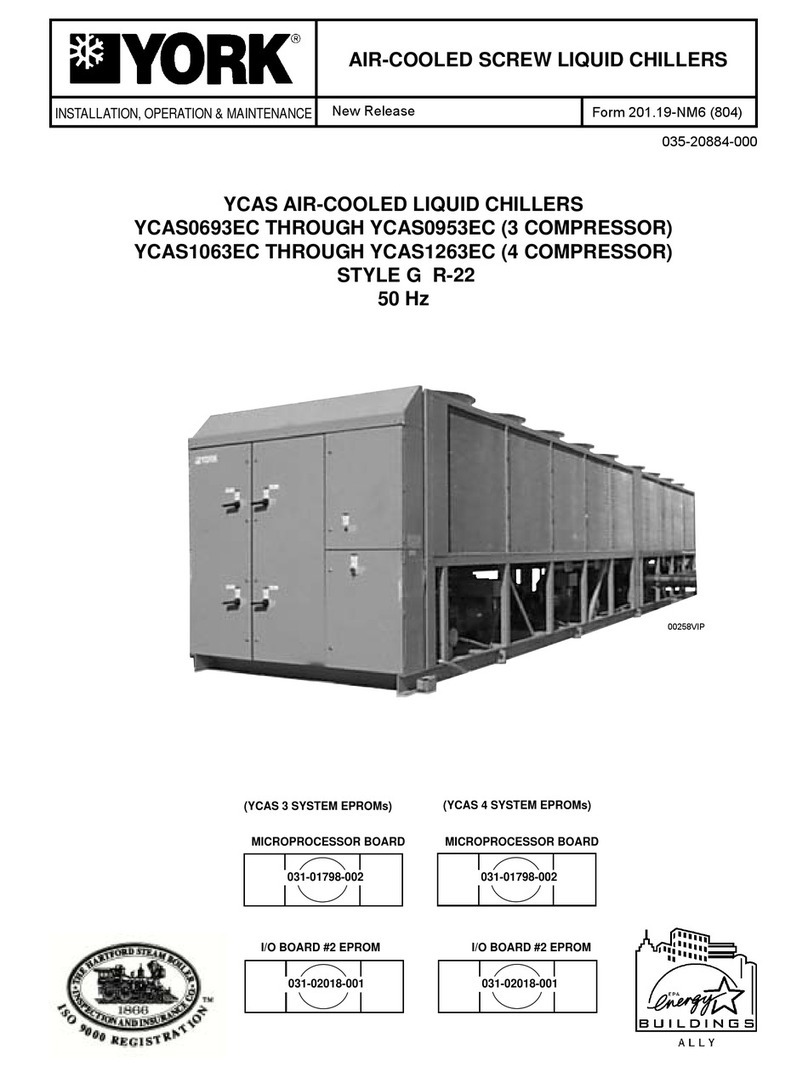

Standard field power wiring connection on all models is Multiple

PointPower Connection to factory provided Terminal Blocks. Two

fieldsupplied electrical power circuitswith appropriate branch cir-

cuit protection provide power to each of two motor control center

cabinets,located on either side of theControl panel on the frontof

the chiller. Each cabinet contains starter elements for one com-

pressor.

Optional to the Terminal Blocks for field power connection are

Non-FusedDisconnectsorCircuitBreakerSwitcheswithexternal,

lockablehandles.

SINGLE POINT POWER CONNECTION - (Factory Mounted) An

optionalconfiguration for field connection of a single electrical cir-

cuitto:either TerminalBlock or Non-Fused Disconnect Switch with

lockableexternalhandle (in compliance with Article 440 of N.E.C.,

to isolate unit power supply for service). Factory wiring is pro-

vided from the Terminal Block or Disconnect Switch to Factory

suppliedindividual system CircuitBreakers,Non-Fused Disconnect

switchwithexternal, lockable handle or J Class Fuses/FuseBlock

ineachofthetwo compressor motor control centers. (Note: Single

PointNon-Fused Disconnect Switch willnot be supplied withindi-

vidualsystemNonFusedDisconnectSwitcheswithexternal,lock-

able handles in each of the two compressor motor control cen-

ters).

65 Ka HIGH VOLTAGE PROTECTION - Non-Fused Disconnect

Switch with fuses (200 & 575V) or Circuit Breakers (230, 380, &

460V) are used for applications where customers have a require-

ment for single point wiring with high “fault current” withstanding

capability.Thisoptionprovidesbetween50Kaand65Kawithstand

protectiontotheequipment.

BUILDING AUTOMATION SYSTEM INTERFACE (Factory

Mounted) – Provides means to reset the leaving chilled liquid

temperature or percent full load amps (current limiting) from the

BAS (Factory Mounted):

• Printed circuit board to accept 4 to 20 milliamp, 0 to 10 VDC,

or dry contact closure input from the BAS.

• AYORK ISN Building Automation System can provide a Pulse

WidthModulated (PWM) signal direct to the standard control

panel via the standard onboard RS485 port.

FLOW SWITCH – The flow switch or its equivalent must be fur-

nished with each unit. 150 PSIG (10.5 bar) DWP – For standard

units.JohnsonControlsmodelF61MG-1CVapor-proofSPDT,NEMA

4X switch (150 PSIG [10.5 bar] DWP), -20°F to 250°F- (29°C to

121°C), with 1" NPTconnection forupright mounting in horizontal

pipe. (Field mounted)

DIFFERENTIALPRESSURESWITCH-Alternativetotheabovemen-

tionedFlow Switch. Pretemco Model DPS 300A-P4OPF-82582-S

(20.7barmax working pressure).SPDT5 amp 125/250VACswitch.

Range:0 - 2.8bar,deadband:0.003- 0.005bar,with1/4 NPTE pres-

sure connections.

LANGUAGE LCD ANDKEYPAD - Standarddisplay languageand

keypadisinEnglish.Spanishis available as an option.

PRINTER KIT - Printer for obtaining printout ofunit operating and

history data. (Field Mounted)

MULTIPLE UNIT SEQUENCE CONTROL (Field Mounted) - Se-

quencingControlwith automatic unit sequencing. Necessary items

for operation and control of up to eight units with parallel water

circuits. Includes software and mixed liquid temperature sensor

(interconnecting wiring by others).

PRESSURE VESSEL CODES - Coolers and condensers can be

supplied in conformance with the following pressure codes:

A.S.M.E.(Standard)

CHICAGOCODE RELIEF VALVES (FactoryMounted)- Unitwillbe

providedwith relief valves to meet ChicagoCode requirements.

ACCESSORIES:

FLANGES (Weld Type) –Consistsof150PSI(10.5bar)standard

cooler (150 lb) R.F. flanges to convert to flanged cooler-connec-

tions and includes companion flanges. (Field mounted)

FLANGES (Victaulic Type) – Consists of (2) Flange adapter for

grooved end pipe (standard 150 PSI [10.5 bar] cooler). Includes

companion flanges. (Field mounted)

VIBRATIONISOLATION:

• Neoprene Isolators – Recommended for normal installations.

Provides very good performance in most applications for the

least cost. (Field mounted)

•1" Spring Isolators – Level adjustable, spring and cage type

isolators for mounting under the unit base rails. 1" nominal de-

flection may vary slightly by application. (Field mounted)

•2"Seismic Spring Isolators– RestrainedSpring-Flex Mountings

incorporate a rugged welded steel housing with vertical and

horizontal limit stops. Housings designed to withstand a mini-

mum1.0gaccelerated force in all directions to 2".Leveladjust-

able,deflection may varyslightlyby application. (Field-mounted)

ALTERNATIVE CHILLEDFLUIDAPPLICATIONS:

Standard waterchillingapplicationrangeis40°Fto50°F(4.4°Cto

10°C)Leaving Chilled WaterTemperature. Toprotect against nui-

sancesafetytripsbelow 40°F(4.4°C)andreducethepossibility of

cooler damage due to freezing during chiller operation, the unit

microprocessorautomatically unloads the compressors at abnor-

mallylowsuction temperature (pressure) conditions,priortosafety

shutdown.

•Process Brine Option – Process or other applications requir-

ing chilled fluid below 40°F (4.4°C) risk water freezing in the

evaporator, typically overcome by using antifreeze. For these

applications,thechiller system incorporates brine (ethylene or

propyleneglycolsolution),andthesystemdesignLeavingChilled

FluidTemperaturemustbeprovided on theorderformtoensure

proper factory configuration.

•Thermal Storage Option – Thermal Storage equires special

capabilitiesfrom a chiller, including the ability to‘charge’ an ice

storagetank, then possibly automatically resetfor operation at

elevatedLeavingChilled Fluid Temperaturesas required by au-

tomaticbuildingcontrols. The Thermal Storage Option provides

Ice Storage duty Leaving Chilled Fluid setpoints from 25°F to

15°F(-4°C to -10°C) minimumduringchargecycle,with a Reset

rangeof36°F (20°C) supply fluid temperature.

Accessories & Options