FORM 160.84-EG1 (617)

JOHNSON CONTROLS 5

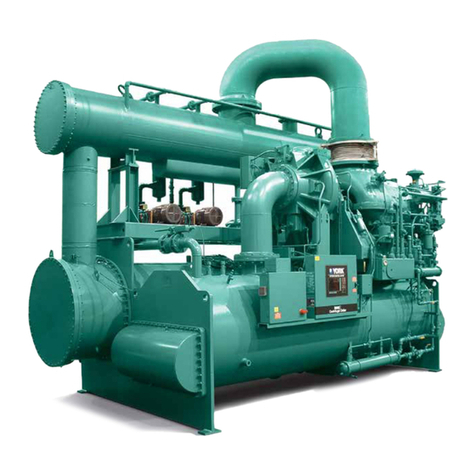

The YORK®YMC² chiller offers a full package of features for total owner satisfaction. Key

benefits include efficiency, sustainability, quiet operation, and reliability.

EFFICIENCY

Actual chiller efficiency cannot be determined by analyzing the theoretical efficiency of

any one chiller component. It requires a specific combination of heat exchanger, com-

pressor, and motor performance to achieve the lowest system kW/ton. YMC² technology

matches chiller system components to provide maximum chiller efficiency under actual –

not just theoretical – operating conditions. The YMC² chiller lowers energy costs with up to

10% better efficiency than existing designs at both full and part-load conditions.

Johnson Controls pioneered the term “Real-World Energy” to illustrate the energy-saving

potential of focusing on chiller performance during off-design conditions. Off-design condi-

tions are not only seen at part-load, but at full-load operation as well, by taking advantage

of reduced entering condenser water temperatures (ECWTs). This is where chillers oper-

ate 99% of the time, and where operating costs add up. YMC² chillers are the only chillers

designed to operate on a continuous basis with cold ECWT and full condenser flow at all

load points, taking full advantage of Real-World conditions. This type of operation benefits

the cooling tower as well by reducing cycling of the fan motor and ensuring good coverage

of the cooling tower fill. YMC² chillers offer the most efficient Real-World operation of any

chiller, meaning lower operating costs and an excellent return on your chiller investment.

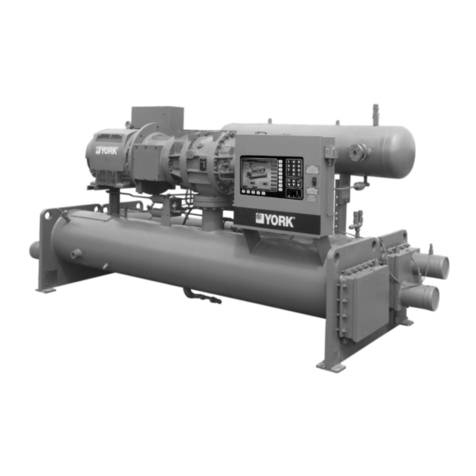

YORK single-stage compressors are designed to reduce energy costs. High strength alu-

minum-alloy compressor impellers feature backward-curved vanes for high efficiency. Dy-

namically-controlled mechanical flow regulation with motor speed allows the compressor

to unload smoothly from maximum to minimum load for excellent part-load performance

in air conditioning applications.

The YMC² chiller's heat exchangers offer the latest technology such as falling-film, in

addition to the latest technology in heat transfer surface design to give you maximum ef-

ficiency, reduced refrigerant charge, and a compact design. The largest unit has only a 14’

(4.3m) heat exchanger length.

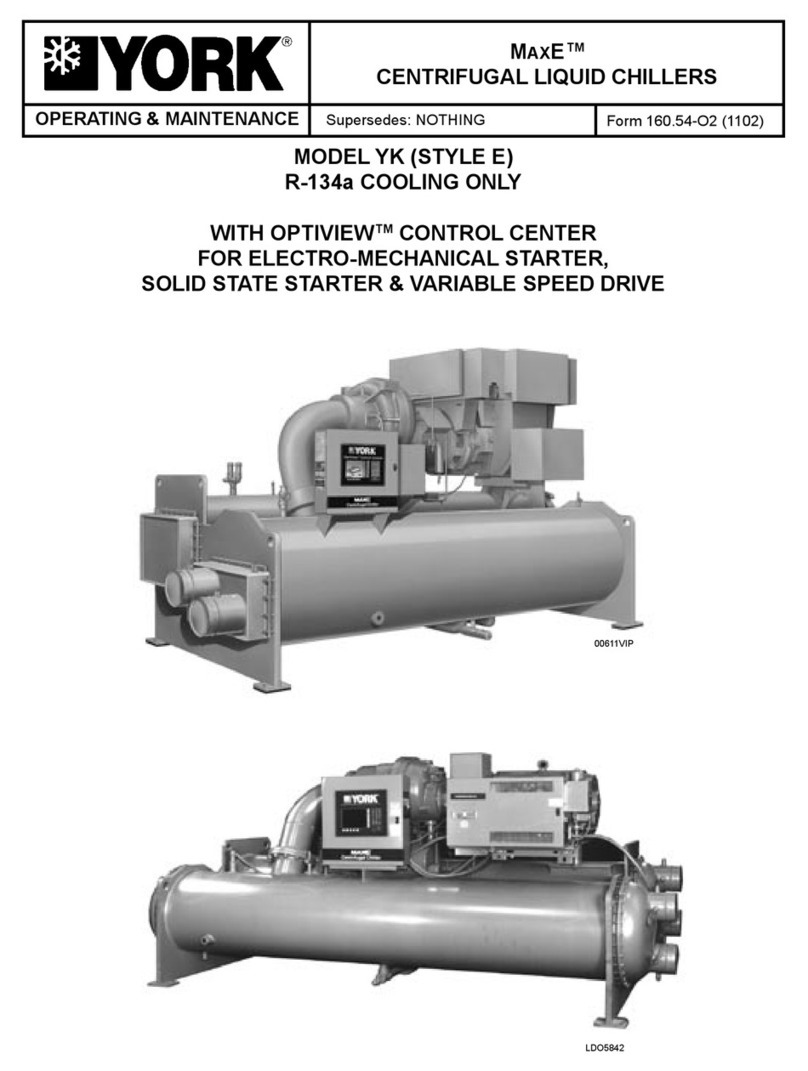

The YORK OptiView™ Control Center, furnished as standard on each chiller, provides the

ultimate in efficiency, monitoring, data recording, chiller protection and operating ease.

The OptiView Control Center is a factory-mounted, wired and tested state-of-the-art mi-

croprocessor-based control system for HFC-134a or HFC-513A centrifugal chillers.

Setpoints can be changed from a remote location via 0-10VDC, 4-20mA, contact clo-

sures or through serial communications. The adjustable remote reset range [up to 20°F

(11.1°C)] provides flexible, efficient use of remote signal depending on reset needs. The

serial data interface to the Building Automation System (BAS) is through the optional fac-

tory mounted E-Link installed inside the Control Center.

Introduction

Off-design is not

only part load, but

full load operation

as well, with reduced

entering condenser

water temperatures

(ECWTs)