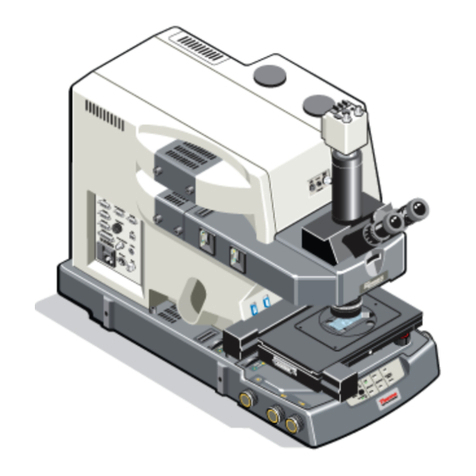

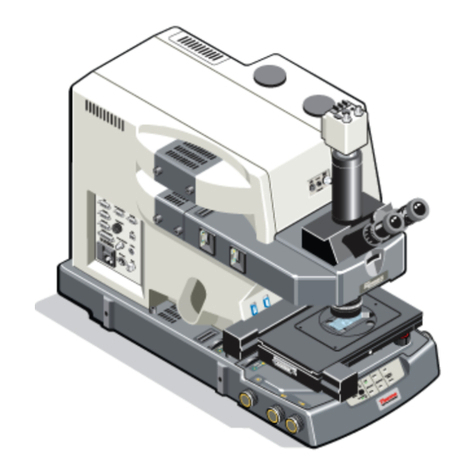

Mechanical stage S mot. CAN INTRODUCTION

Measuring stage S mot. CAN Notes on instrument safety Carl Zeiss

08/2012 435465-9000-701 7

1.2 Notes on instrument safety

The mechanical stage / measuring stage S mot. CAN may only be used for the applications

described in this operating

manual. The manufacturer cannot assume any liability for other

applications of the instrument, including those of individual modules or single parts.

Modifications and repairs to this instrument and any devices operated in combination with the

microscop

e must be carried out by our service department or by authorized personnel only. The

manufacturer accepts no liability for damage caused by unauthorized access to the interior of

the instrument. Failure to comply with this shall also render any warranty claims invalid.

The device may only be operated by instructed personnel. The instruments may only be

operated by trained personnel who are aware of the possible dangers involved with microscopy

and the application concerned. The microscope is a high-

precision instrument that can be

impaired in its performance or destroyed when handled improperly.

The mains plug of instruments with a metal housing (e.g. EMS 3) may only be connected to a

socket with earth contact. The protective capacity must not be rendered ineffective by using an

extension cable without a ground wire.

If it is determined that protective measures are no longer effective, the instrument must be

switched off and secured against inadvertent operation. Please contact a Zeiss

the Carl Zeiss Microscopy Service to repair the instrument.

Dust and dirt may impair the instrument’s performance. The instrument must be effectively

protected from such influences and covered with the dust cover when not in use. Alway

s check

whether the instrument is switched off before you cover it. Broad temperature fluctuations,

direct sunlight and vibrations should be avoided.

The instruments are not equipped with special devices to protect against corrosive, potentially

infec

tious, toxic, radioactive or other substances that may be hazardous to health. All legal

regulations must be observed when handling such substances, particularly the relevant national

accident prevention regulations.

Defective instruments are not to be disposed of as ordinary domestic waste. They should be

disposed of in accordance with the relevant regulations.

Samples should also be disposed of in compliance with the relevant legal requirements and

internal operating procedures.

Before setting up the instrument, check whether it is suitable for the available line voltage.

Always disconnect the instrument from the power outlet before opening it and changing the

fuses.

Only the specified fuses may be used.

The use of makeshift fuses and short-circuiting of the fuse holders are not permitted.

Controller EMS 3 supplies voltage to the mechanical / measuring stage S 150 x 100 mot. CAN.

The EMS

3 permits mains voltages in the 100 to 240 V ±10% 50/60 Hz range without

additional change in the voltage.

Operation of the instrument in explosive environments is not permissible.