© Zennio Avance y Tecnología S.L. Edition 7 Further information www.zennio.com Page 2/2

SAFETY INSTRUCTIONS ANDADDITIONAL NOTES

•Installation should only be performed by qualified professionals according to the laws and regulations applicable in each country.

•Do not connect the mains voltage nor any other external voltage to any point of the KNX bus; it would represent a risk for the entire

KNX system. The facility must have enough insulation between the mains (or auxiliary) voltage and the KNX bus or the wires of other

accessories, in case of being installed.

•The facility must be equipped with a device that ensures the omnipolar sectioning. Installation of a 10 A mini-circuit-breaker is

recommended. To prevent accidents, it must remain open in case of manipulation of the device.

•The device has a short-circuit protection fuse that, in case of activation, should only be rearmed or replaced by the Zennio technical

service.

•This device contains a security short-circuit proof transformer.

•Once the device is installed (in the panel or box), it must not be accessible from outside.

•Keep the device away from water (condensation over the device included) and do not cover it with clothes, paper or any other material

while in use.

•The WEEE logo means that this device contains electronic parts and it must be properly disposed of by following the instructions at

https://www.zennio.com/en/legal/weee-regulation.

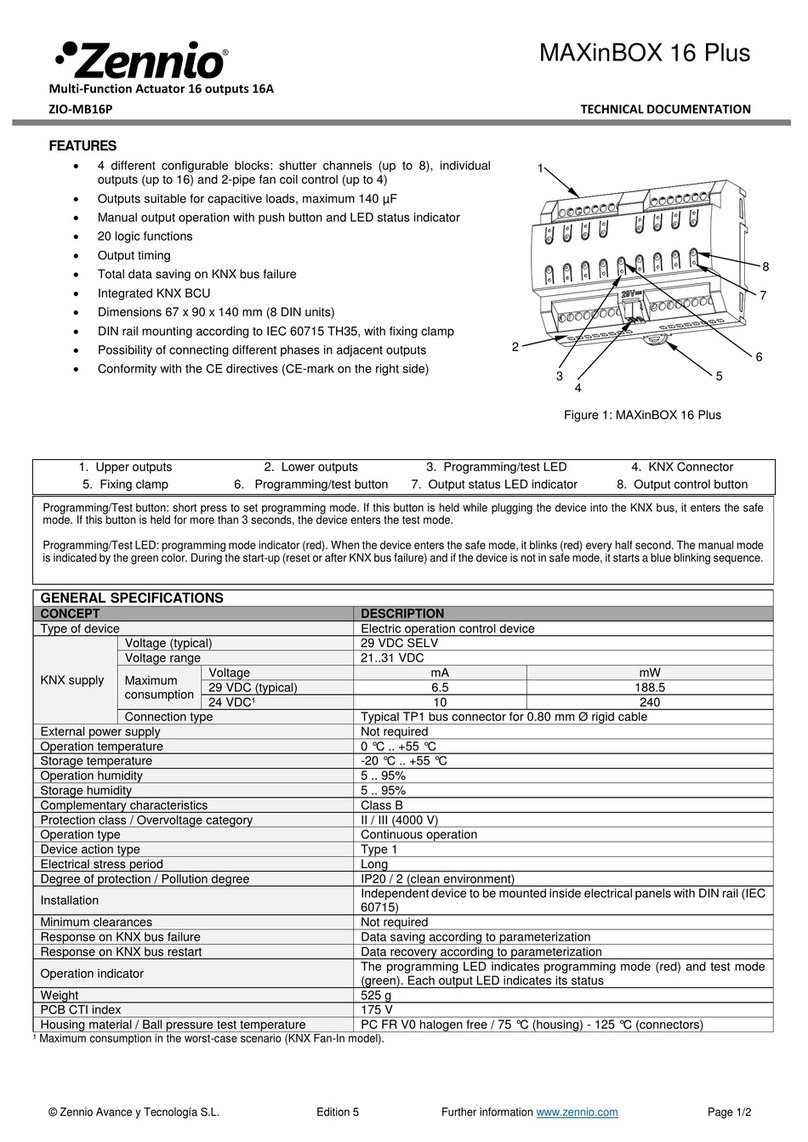

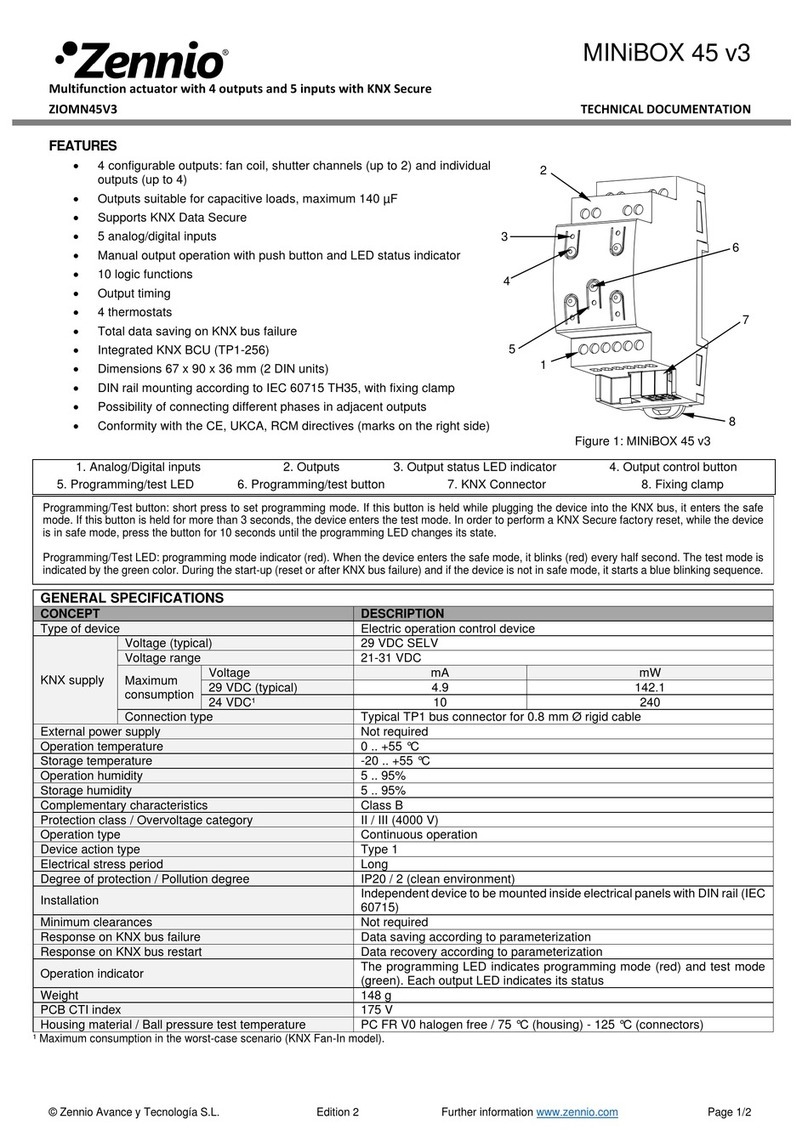

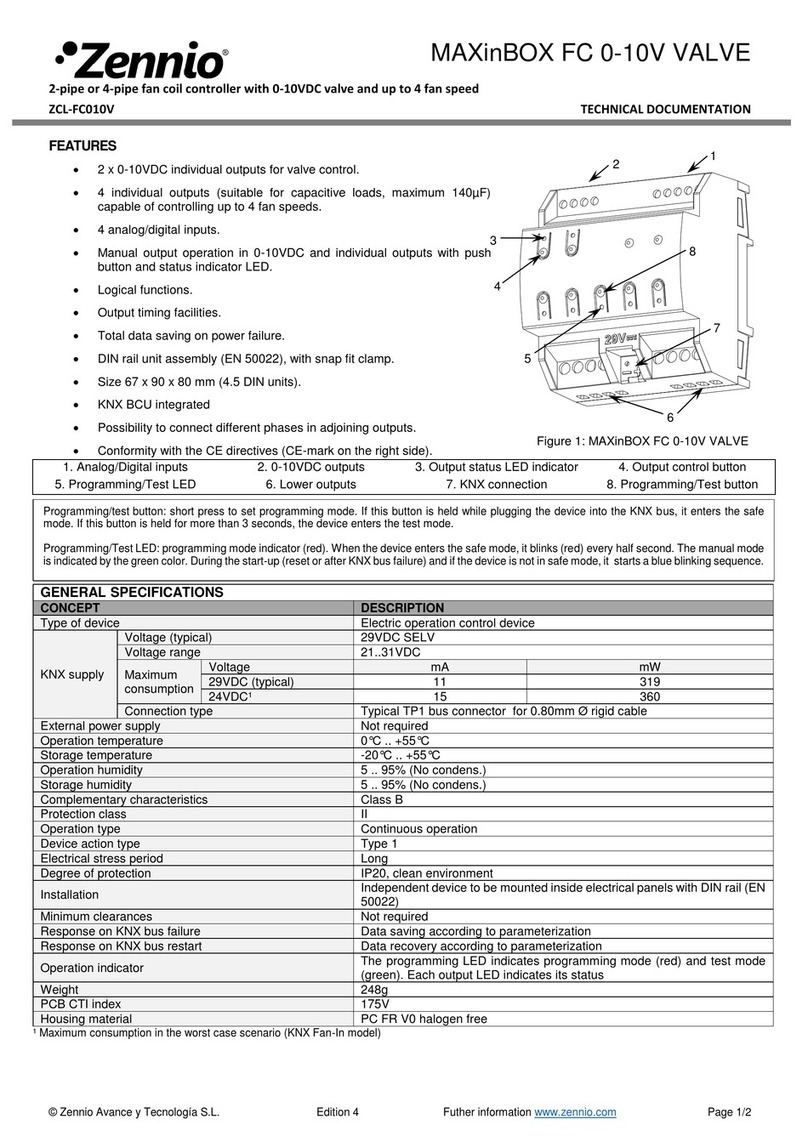

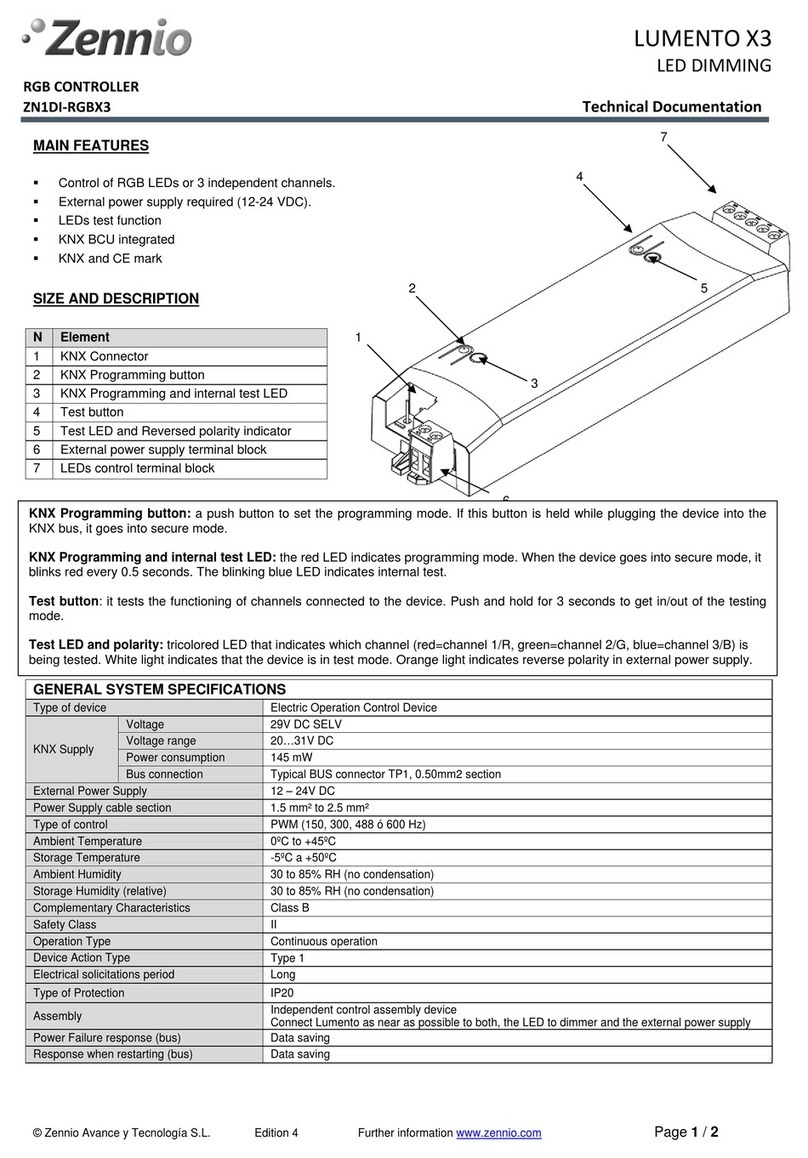

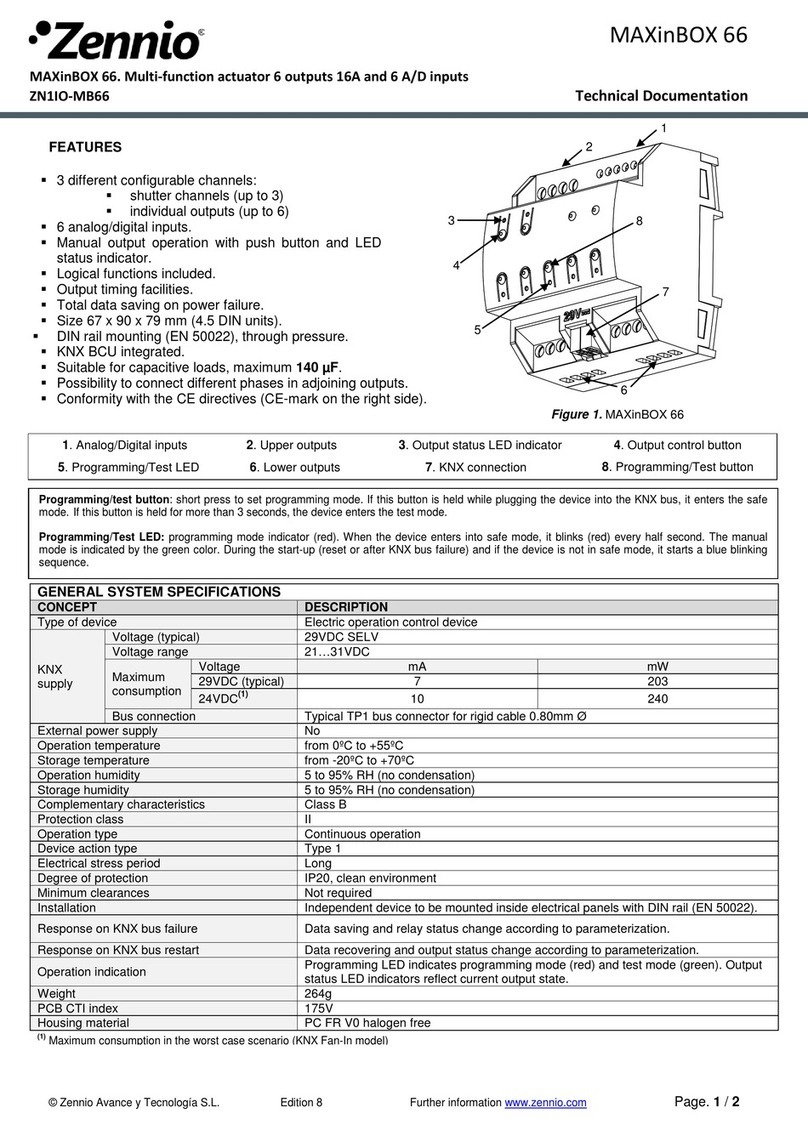

OUTPUTS SPECIFICATIONS AND CONNECTIONS

Solid state switching device / 12 or

24 VDC (selected by switch)

Maximum values

per output

Screw terminal block (0.5 Nm max.)

0.5-2.5 mm² (IEC) / 26-12 AWG(UL)

²This value could be more restrictive depending on the current consumed by the grille.

EXTERNAL POWER SUPPLY SPECIFICATIONS AND CONNECTIONS

Power supply

protection fuse

Screw terminal block (0.5 Nm max.)

1.5-4 mm² (IEC) / 26-10 AWG (UL)

Figure 2: Error notification through

grille status LED

Notes:

•The simultaneous connection of a grille to several outputs nor the connection of 12 VDC and 24 VDC grilles at the same

time is not allowed.

•In case of connecting two grilles to an output, those must have similar consumption characteristics.

•The polarity of the connection must be checked. This can be done, under the Test On mode, through the grille control

buttons: the first press should imply an attempt to open the grille, while the second press should cause an attempt to close

it. Once the device is parameterized, switched-on LEDs should correspond to open grilles.

•After connecting a grille, a synchronisation must be provoked (for example, disconnecting and connecting the KNX bus).

•Compatibility of grilles must be checked following the next steps for a complete verification:

1. The grille must be connected to an enabled output, without other grilles in that output, (Please be careful to ensure the

polarity is respected).

2. The device must be fed with auxiliary power and then connected to the KNX bus.

3. The grilles connected to outputs try a sequential opening movement. In positional mode, a maximum time of 25.5 s to

complete the opening movement is allowed. In open/close mode, the maximum time is 3.5 s to complete the opening

movement.

4. Next, the grilles connected to outputs try a sequential closing movement. If the grille does not complete the closing

movement, it is not suitable for ZoningBOX.

Two grilles per output

connection schematic

Attaching ZoningBOX 6 to DIN rail:

Removing ZoningBOX 6 from DIN rail:

0,5

1,0

1,5

2,0

2,5

3,0

3,5

Description: