ii

Setup .............................................................................................................................................. 25

Standby........................................................................................................................................... 27

Run - Treatment Modes .................................................................................................................. 27

User Interface ....................................................................................................................................... 28

Display Screen ................................................................................................................................. 28

Changing Target Temperature......................................................................................................... 30

Changing Treatment Mode ............................................................................................................. 30

Console Menus .................................................................................................................................... 33

Hi/Lo Patient Temperature Alarms ................................................................................................... 34

Bath Pre-set..................................................................................................................................... 35

Time and Date................................................................................................................................. 36

ºC/ºF (Temperature Notation) .......................................................................................................... 37

Language ........................................................................................................................................ 38

Standby Timer ................................................................................................................................. 38

T1/T2 Behavior ..................................................................................................................................... 39

First Use Warning – No T2 Probe ..................................................................................................... 40

T2 Probe Disconnection/Reconnection .............................................................................................40

Accidental Disconnection T1/T2 Probe ............................................................................................. 41

Alarms & Alerts .................................................................................................................................... 41

Alerts ................................................................................................................................................... 41

Alarms.................................................................................................................................................. 42

Your First Case ..................................................................................................................................... 43

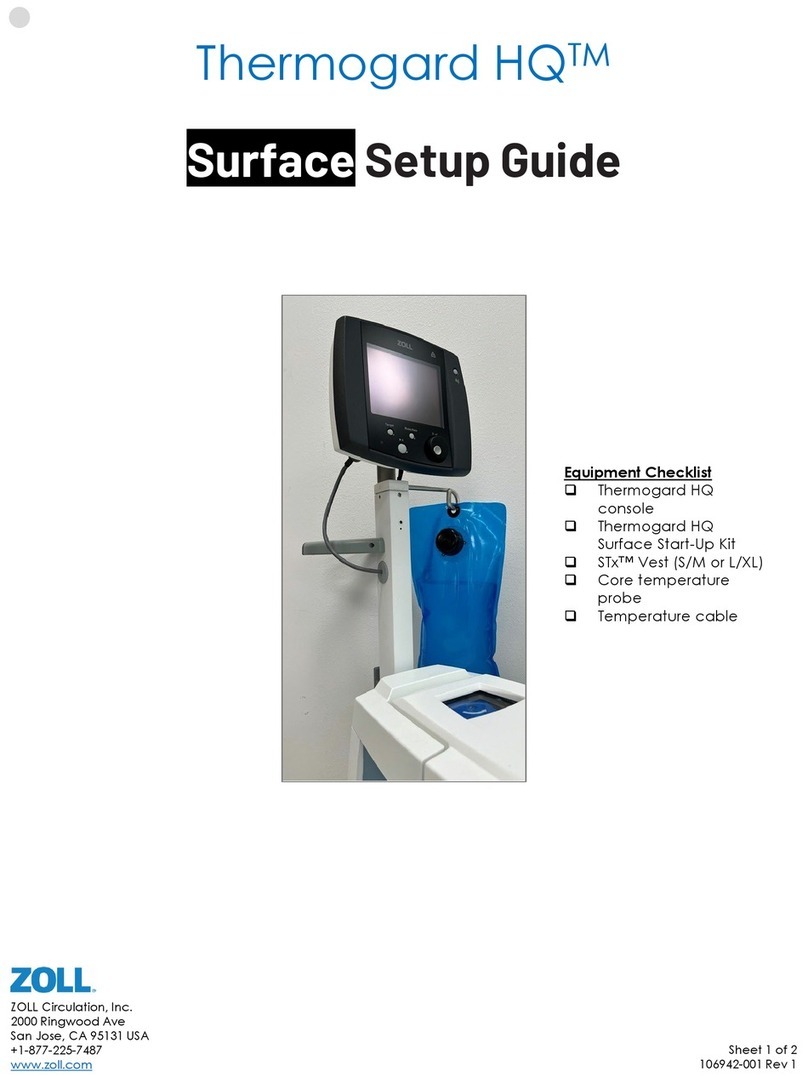

What you need..................................................................................................................................... 43

Preparing the Console for Treatment .................................................................................................... 44

Installing the Start-Up Kit ................................................................................................................ 49

Setup - Variations ................................................................................................................................. 60

Setup Sequence.................................................................................................................................... 60

Time From Last Power Down ........................................................................................................... 60

Downloading Data After Improper Shutdown....................................................................................... 61

Ending Treatment................................................................................................................................. 65

End Procedure................................................................................................................................. 65

Data Download ............................................................................................................................... 65

New Patient – No Power Down............................................................................................................. 68

Change the Start-Up Kit .................................................................................................................. 68

Delete Previous Patient Data............................................................................................................ 68

Disposal of Used Components .............................................................................................................. 68

Temperature Trend Data....................................................................................................................... 69

Overview......................................................................................................................................... 69

Displaying the Temperature Trend Graph.............................................................................................. 69

Temperature Trend Graph .................................................................................................................... 70

Patient Temperature........................................................................................................................ 71

System Activity ................................................................................................................................ 71

Cursor............................................................................................................................................. 71

Status Bar........................................................................................................................................ 71

Setting the Time Scale .......................................................................................................................... 72

Mechanical Components ...................................................................................................................... 73