Zakład Wytwórczy Aparatów Elektrycznych Sp. z o.o.

4

1. DELIVERY METHOD

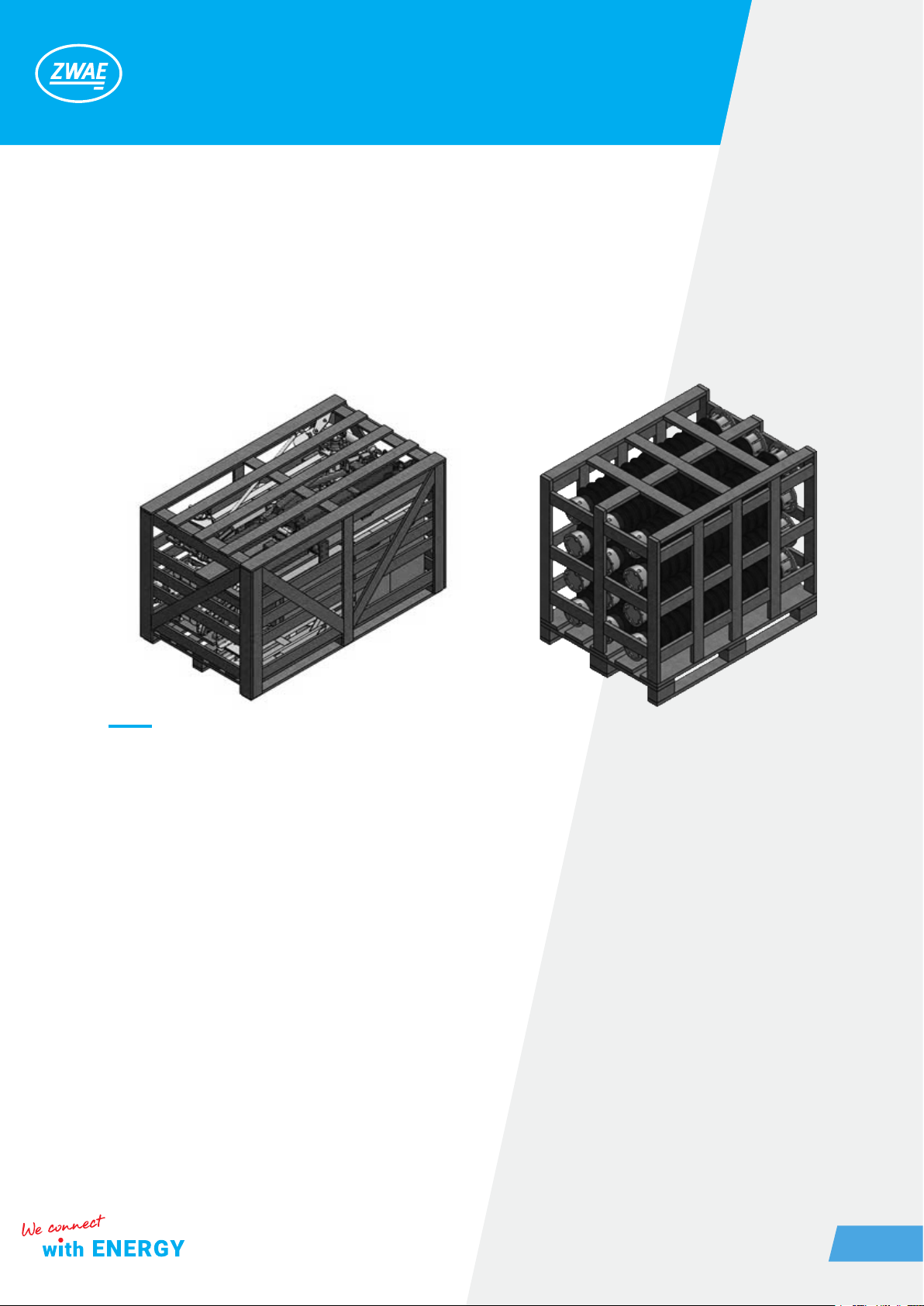

ONIII-123 outdoor disconnectors are delivered to the customer partially assembled. The bases of individual dis-

connector poles, current paths, coupling elements, drives and structures for suspending the drives are placed in

a wooden crate (1 crate contains 3 disconnector poles). The insulators are delivered in a separate wooden box.

2. DISCONNECTOR’S RECEIPT

Check if the disconnector and the accessories, meet the shipping specications. You should also check if the

delivery is not mechanically damaged. In the event of any non-compliance or damage, notify the manufacturer

immediately.

3. MOVING

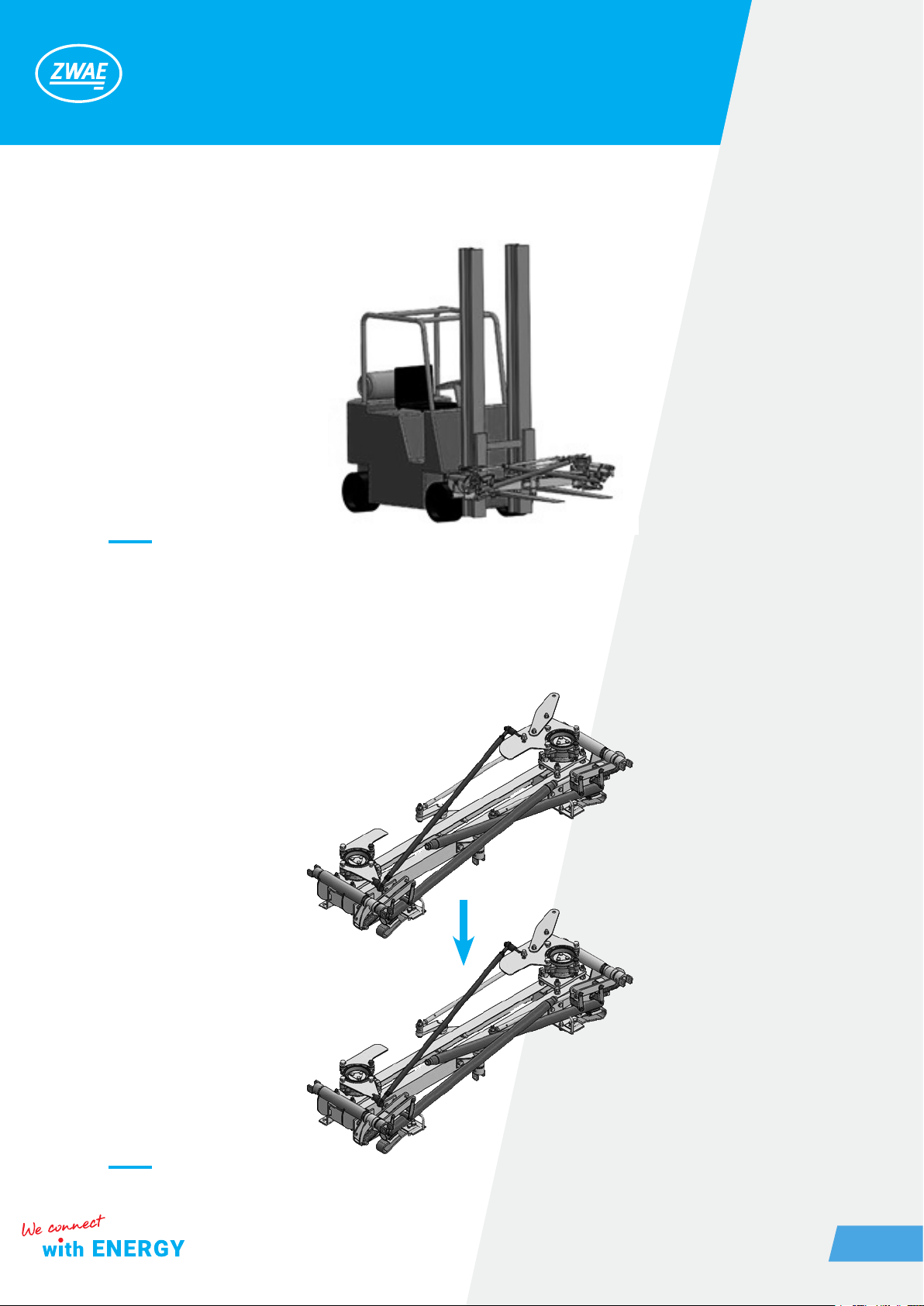

Crates with ONIII-123 disconnector parts can be safely moved with a forklift. It is allowed to lift the crates one

at a time, by the pallet base, on either side of the crate.

Fig. 1, 2. Shipping crates. Left – disconnectors’ parts, right – insulators