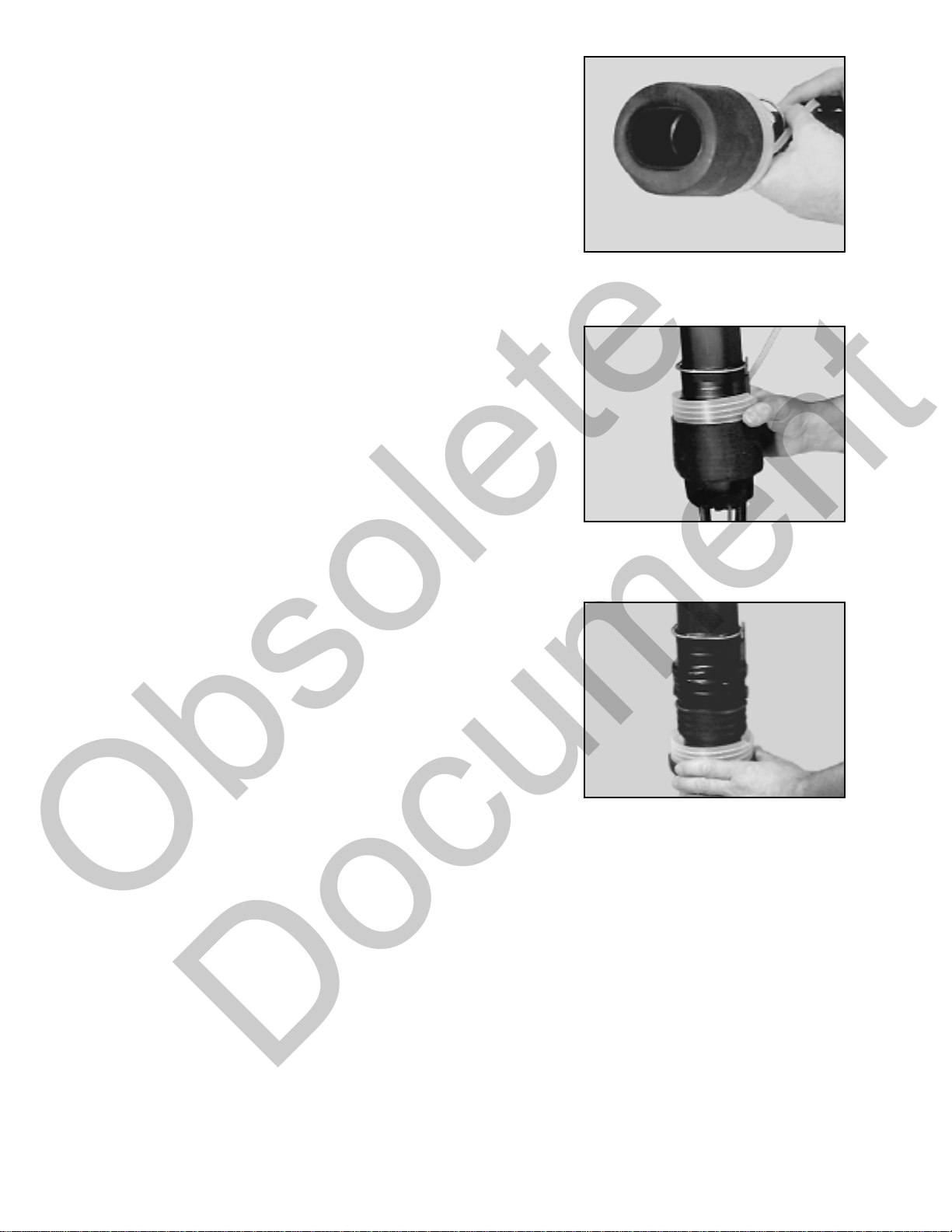

8.3 Trim off excess gel wrap if needed. Make sure that the top of the

bundle is fully covered prior to trimming gel wrap.

8.4 Starting 2" (51 mm) below the gel end seal, begin tightly wrapping

the elastic vinyl film. Continue tightly wrapping the elastic vinyl

film over the length of the gel wrap and bundle. Make certain that

the top of the gel wrap is tightly covered by the elastic vinyl film.

Wrap three highly stretched layers of elastic vinyl film. Secure the

end of the elastic vinyl film with vinyl tape.

7.5 Pull cables together with tape or cable ties to ensure proper fit to

closure.

8.0 Gel Wrap Installation – 4604GW and 4606GW

8.1 Starting at bonding connectors, begin wrapping elastic vinyl film.

Continue wrapping the elastic vinyl film along the bundle until the

bundle is fully covered.

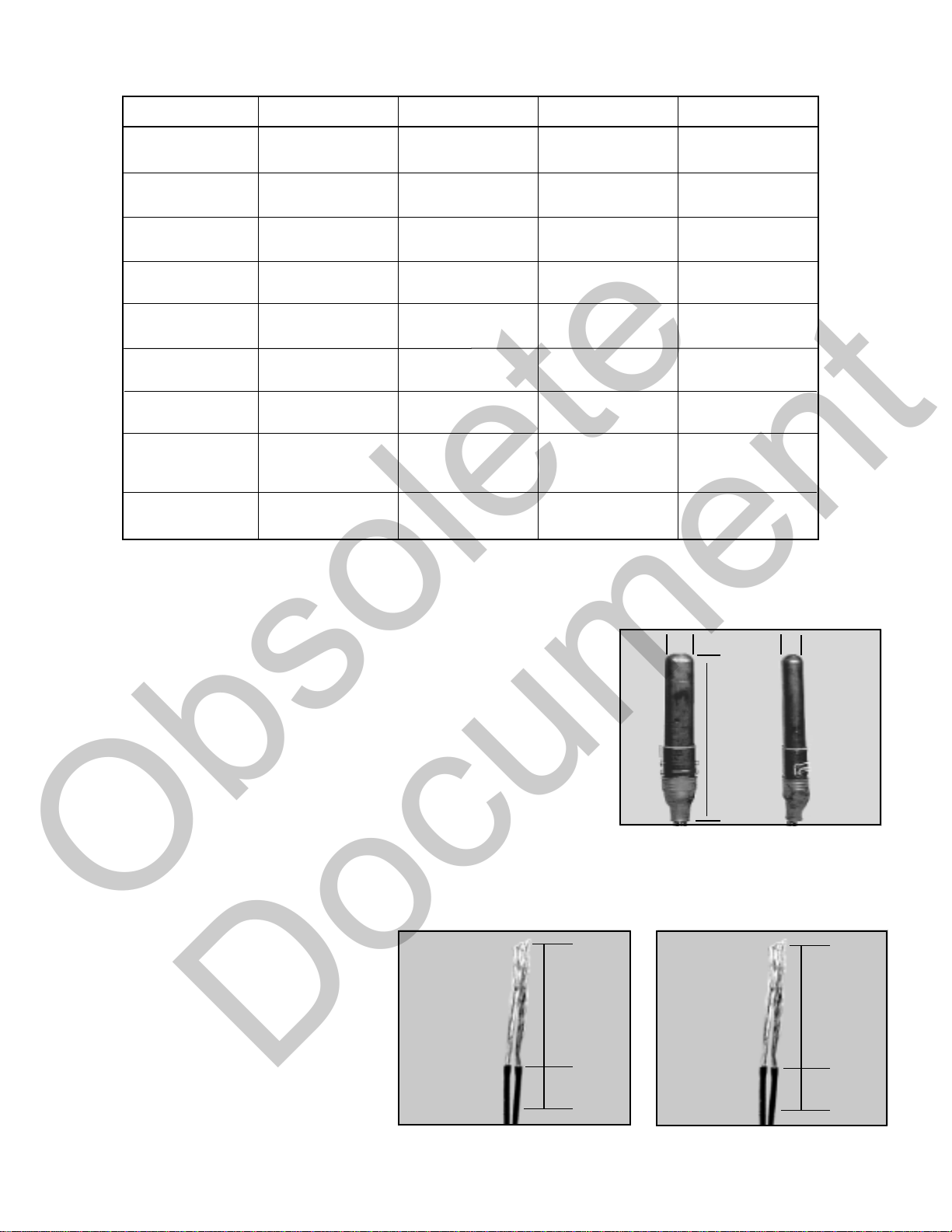

8.2 To install gel wrap, first remove the protective cover from one side.

Place the gel wrap behind the cables (the unprotected side should

face the bundle); position it so that the lower edge is near the bottom

of the end seal. Anywhere between the bottom and middle of the

end seal is acceptable. At this time remove the remaining protective

cover from gel wrap.

Wrap the gel wrap around the end seal so that the ends overlap and

press them firmly together. Continue wrapping the gel wrap along

the bundle, assuring that the ends overlap, until the bundle is fully

sealed.