2

Equipment Warranty and Limited Remedy: THE FOLLOWING WARRANTY IS MADE IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTY OF MERCHANTABILITY, THE IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR

PURPOSE AND ANY IMPLIED WARRANTY ARISING OUT OF A COURSE OF DEALING, A CUSTOM OR

USAGE OF TRADE:

3M sells its 3M-MaticTM 120af3 Adjustable Case Sealer, Type 19600 with the following warranties:

1. The Taping Head knife, springs and rollers will be free from all defects for ninety

(90) days after delivery.

2. All other Taping Head parts will be free from all defects for three (3) years after delivery.

3. The motor will be free from all defects for one (1) year after delivery.

4. All other parts will be free from all defects for ninety (90) days after delivery.

If any part is proved to be defective within its warranty period, then the exclusive remedy and 3M’s and seller’s

sole obligation shall be, at 3M’s option, to repair or replace the part, provided the defective part is returned

immediately to 3M’s factory or an authorized service station designated by 3M. A part will be presumed to have

become defective after its warranty period unless the part is received or 3M is notified of the problem no later

than five (5) calendar days after the warranty period. If 3M is unable to repair or replace the part within a

reasonable time, then 3M, at its option, will replace the equipment or refund the purchase price. 3M shall have

no obligation to provide or pay for the labor required to install the repaired or replacement part. 3M shall have

no obligation to repair or replace (1) those parts failing due to operator misuse, carelessness, or due to any

accidental cause other than equipment failure, or (2) parts failing due to non-lubrication, inadequate cleaning,

improper operating environment, improper utilities or operator error.

Limitation of Liability: 3M and seller shall not be liable for direct, indirect, special, incidental or consequential

damages based upon breach of warranty, breach of contract, negligence, strict liability or any other legal

theory.

The foregoing Equipment Warranty and Limited Remedy and Limitation of Liability may be changed only by a

written agreement signed by authorized officers of 3M and seller.

ScotchTM,AccuGlideTM, and 3M-MaticTM are Trademarks of 3M, St. Paul, Minnesota 55144-1000

Contents – 120af3 Adjustable Case Sealer

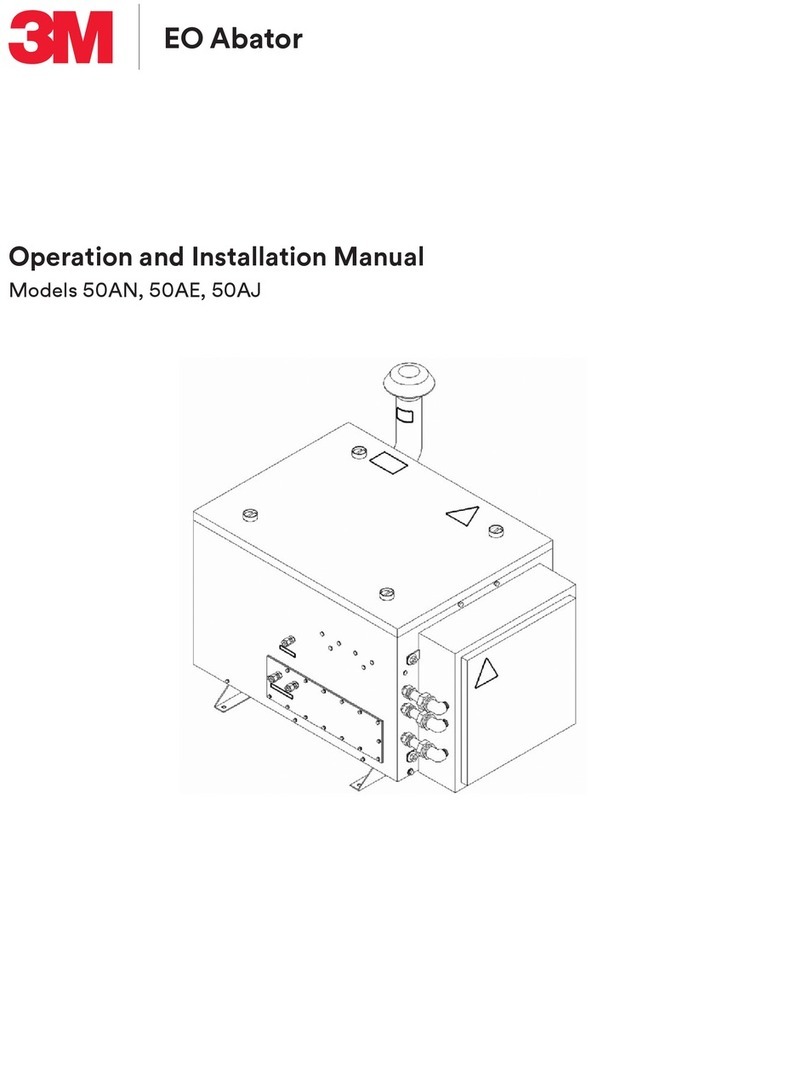

(1) 120af3 Adjustable Case Sealer, Type 19600

(1) Tool/Spare Parts Kit

(1) Instruction and Parts Manual