5

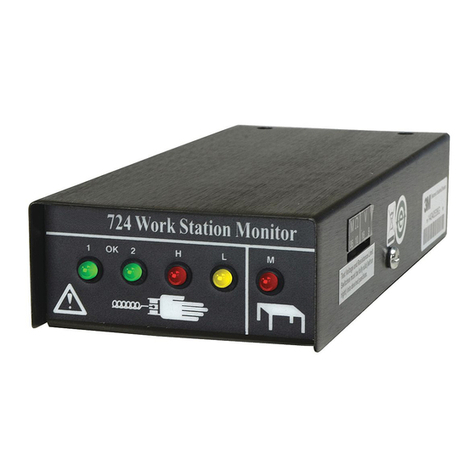

The Model 724 monitor allows for the

selection of test voltages (9v or 16v)

and resistance limits (10 Megohms or

35 Megohms). The additional ranges

have been added to accommodate

global Electrical Static Discharge

requirements. Selection of the

operating parameters are left up to the

user’s discretion (See Section 4).

Operator Monitoring -

Single and Dual

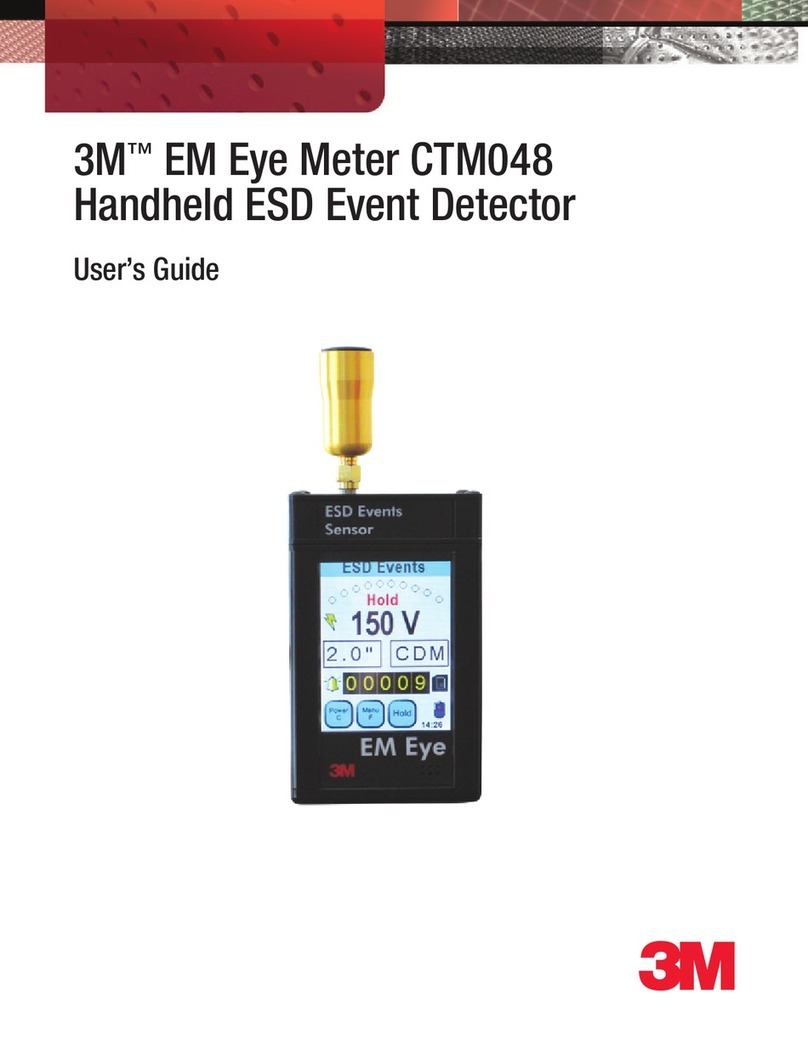

Fig. 3 - Face of Model 724

The wrist strap monitoring function

is activated by plugging a wrist strap

dual conductor ground cord into either

one of the jacks on the 3M™Models

732/733 Dual Conductor Remote

Input Jack. If the resistance of the

wrist strap loop is within the limits of

the selected range (1.5 Megohms to

10 Megohms or 1.5 Megohms to 35

Megohms)* on the Model 724

Monitor, the cord, the wrist band, and

the contact to the arm of the wearer, it

is considered to be functioning

correctly. At this time, one of the

(OK) green lamps (1 or 2) will be

illuminated on the front of

the monitor.

If the resistance of the wrist strap

loop is higher than the selected range

(10 Megohms or 35 Megohms)* on the

724 monitor, an (OK) wrist strap green

lamp (1 or 2) extinguishes, and

a high wrist strap red lamp (H)

illuminates with an audible alarm. This

is an indication of a high resistance in

the cord band, or poor contact between

arm and band. If the resistance in the

loop is under 1.5 Megohms,* it is an

indication of a low resistance meaning

one or both current-limiting resistors

are bypassed. The low yellow lamp (L)

will flash and an (OK) green lamp

(1 or 2) will remain illuminated.

Caution

A low resistance condition can also

be caused by touching a grounded

object or by standing on a

conductive surface.

The wrist strap of a second operator

is measured in the same way. Operators

are identified by the two (OK) green

lamps (1 & 2). However, the same high

wrist strap red lamp (H) and low

yellow (L) lamps illuminate when a

fault is detected. The green lamp that

extinguishes identifies the operator that

is experiencing the fault condition.

* Resistance values are ±15%

3M 733 Remote Splitter Kit purchased separately.

OK #1

Operator OK #2

Operator

Resistance High Operator

Resistance Low Operator

Resistance High

Work Surface