Table of Contents

I. INTENDED USE.................................................. 1

II. USER RESPONSIBILITY ...................................... 1

III. ENVIRONMENTAL OPERATING CONDITIONS.......2

IV. INSTRUMENT SPECIFICATIONS .......................... 2

V. LIMITED WARRANTY .........................................3

VI. LIMITED WARRANTY AND DISCLAIMER .............. 3

VII. LIMITATION OF LIABILITY .................................3

VIII. PRODUCT DESCRIPTION .................................... 3

IX. HOW TO USE THIS MANUAL............................... 4

X. HOW TO OPERATE THE 3M CLEAN‑TRACE

LUMINOMETER .................................................. 4

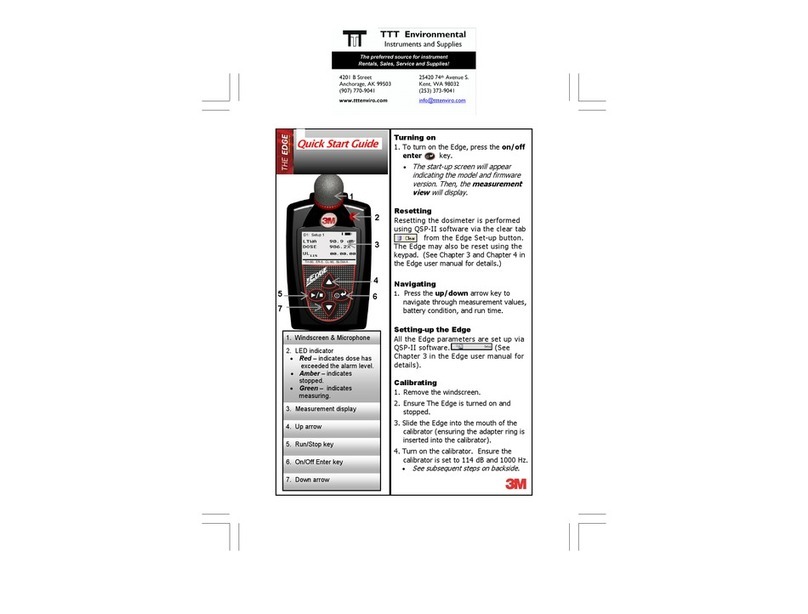

a.

Operating Controls of the 3M Clean

‑

Trace

Luminometer

...................................................... 4

b.

Inserting and removing 3M™ Clean-Trace™ test

swab into the LM1 Luminometer

........................ 5

c.

Using the Base

................................................... 5

d.

Battery usage and maintenance

.........................5

e.

Charging the battery

.......................................... 5

f.

When the battery is charged

.............................. 6

g.

The battery level indicator

..................................6

h.

Power management

........................................... 6

i.

Waking the 3M™ Clean

‑

Trace™ Luminometer

from Sleep Mode

................................................7

j.

3M Clean-Trace Luminometer Calibration

........... 7

k.

How to turn “On” the 3M™ Clean-Trace™ LM1

Luminometer

...................................................... 8

l.

The Diagnostic check

.........................................8

m.

Turning Off or Restarting the 3M™ Clean

‑

Trace™

Luminometer

...................................................... 9

n.

Controlling the Software

.....................................9

o.

How to Sign in on the 3M™ Clean

‑

Trace™ LM1

Luminometer

.................................................... 10

1. On un-registered Luminometer .................................10

2. On registered Luminometer –no Pin required ............10

3.

On registered Luminometer –Pin required

..............11

p.

The Swab Sensor and the Vertical Position Sensor

........................................................................ 12

q.

How to look-up Calibration date and Software

details

.............................................................. 12

r.

How to Sign out of the 3M Clean

‑

Trace LM1

Luminometer

.................................................... 12

XI. HOW TO PERFORM A QUICK TEST OR

UNPLANNED TEST ........................................... 13

a.

Performing an Unplanned test from an un-

registered Luminometer

....................................... 13

b.

Performing an Unplanned test from a registered

Luminometer

........................................................ 13

XII. HOW TO PERFORM A PLANNED TEST RUN............ 15

a.

Performing a Test run on a Test Point within a

Sample Plan

......................................................... 15

b.

Restarting an incomplete Sample Plan

.................. 15

c.

Performing an ATP Test run

................................. 16

d.

Performing a Retest on an ATP Test point before

Moving to a Different Test point

........................... 17

e.

Performing a Retest on an ATP Test point after

Moving to a Different Test point

........................... 17

f.

Performing a Visual Inspection Test on a Test Point

............................................................................ 18

g.

Adding a Comment to a Test result

...................... 18

h.

Recording Temperature or pH for a Test point within

a Sample plan

...................................................... 19

i.

Moving to another Test point in the same Sample

plan

..................................................................... 19

j.

Moving to another Test point in a different Sample

plan

..................................................................... 20

k.

Viewing Test results

............................................. 20

XIII. HOW TO SYNCHRONIZE THE 3M™ CLEAN‑TRACE™

LM1 LUMINOMETER ............................................. 21

a.

Definition

............................................................. 21

b.

Setting up Synchronization with a USB Connection

22

c.

Setting up Synchronization with a Bluetooth

Connection

........................................................... 22

d.

Setting up Synchronization with a Wi-Fi Connection

............................................................................ 23

e.

Setting Wi-Fi auto Synchronization Time

.............. 24

XIV. PERFORMING ADMINISTRATIVE TASKS ................ 25

a.

Setting the Date, Time and Time zone on the 3M™

Clean

‑

Trace™ Luminometer

................................. 25

b.

How to adjust the date/time on the 3M™ Clean-

Trace™ LM1 Luminometer ..................................... 25

c.

Setting the Time zone............................................ 26

d.

Changing Sleep timeout

....................................... 26

e.

Changing the Screen Brightness

........................... 26

f.

Resetting the 3M™ Clean-Trace™ Luminometer

... 27

g.

Looking up Calibration date and device software

details

.................................................................. 27

h.

Troubleshooting

................................................... 28

XV. APPENDIX ........................................................... 30

Cleaning and decontaminating the 3M Clean

‑

Trace

Luminometer

...................................................... 30