6

SECTION 2

Operating Your System

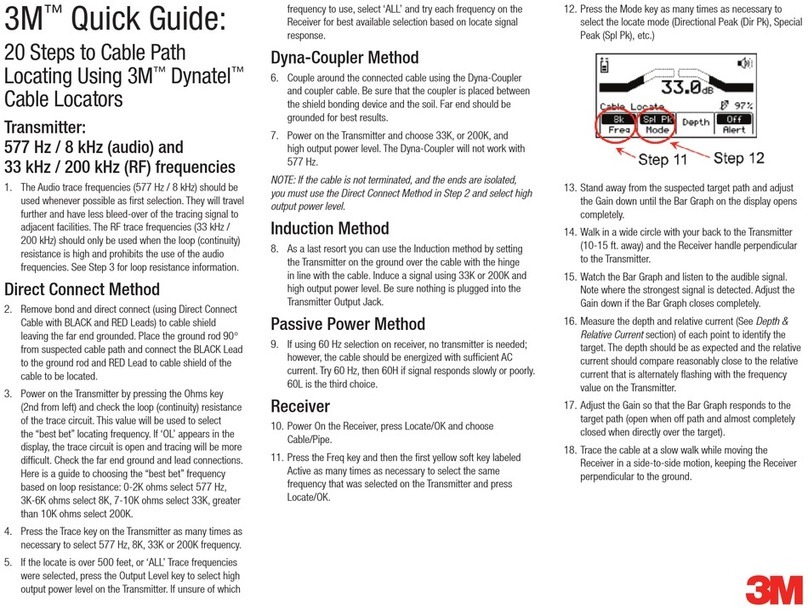

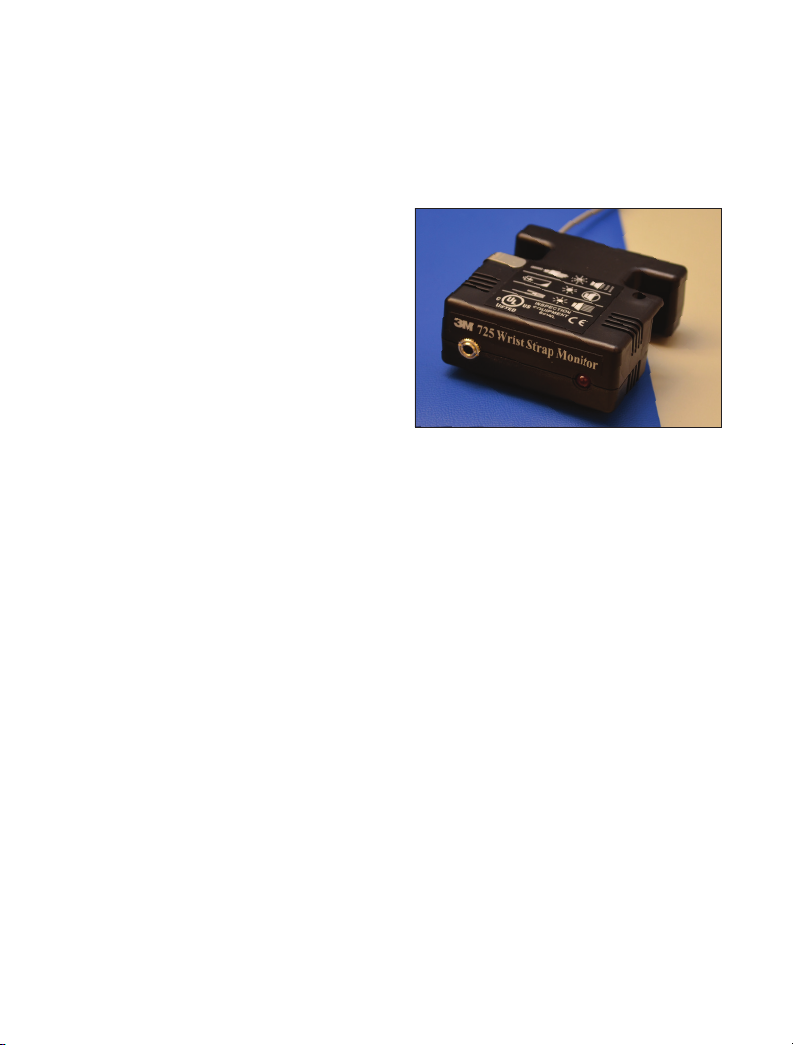

To operate the 3M™Wrist Strap Monitor Model 725, attach the monitor’s (6 ft.)

ground cord with dual conductor ground clip to a suitable ground.

Attach a 3M™Dual Conductor Ground

Cord to a 3M™Dual Conductor Wrist

Band. Place the wrist band on your

wrist and plug the cord into the jack

on the front of the Wrist Strap Monitor

Model 725. Plugging into the jack

activates the monitor and causes it to

emit a short beep and the red lamp

to momentarily flash. If the red lamp

flashes with an intermittent audible

alarm or at any time during use, the

resistance of the wrist strap assembly

is greater than 35 megohms.** If

the red lamp and the audible alarm

remain on continuously, check the dual

conductor ground clip connection.

The system is now ready for use.

**Resistance values are ±15%

Note: Operators may complain that the alarm

is sounding too often until they learn to

adjust the wrist band to fit securely or apply

an approved skin moisturizer on a frequent

basis. Please remember that the monitor is

informing you that the operator is exceeding

the established static control requirement for

resistance to ground when wearing a static

protective wrist strap assembly. These alarms

alert the operator when sensitive electronics

are possibly being exposed to static electricity.

Prior to incorporating the wrist strap monitor

into your static control process, the operator

could be unaware of these events.

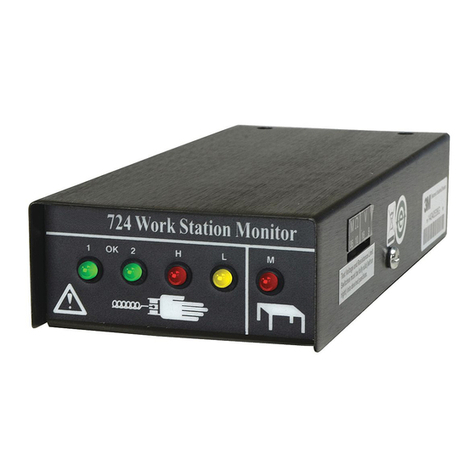

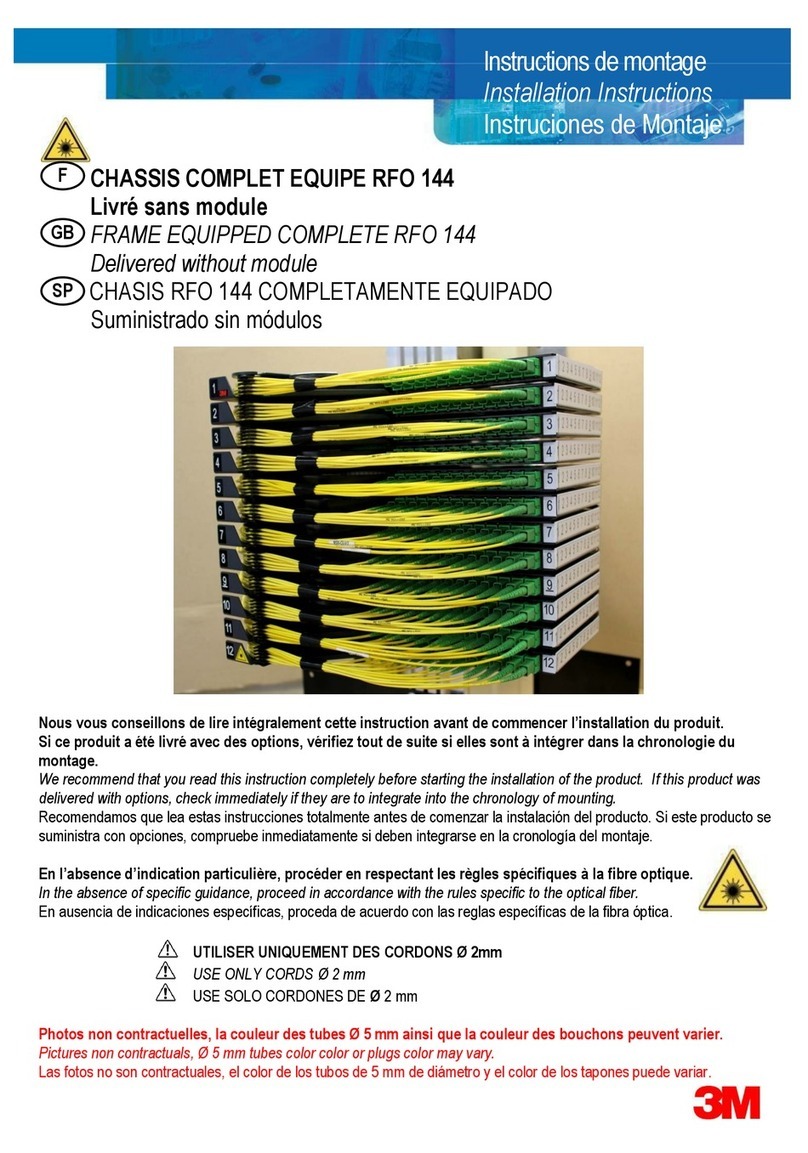

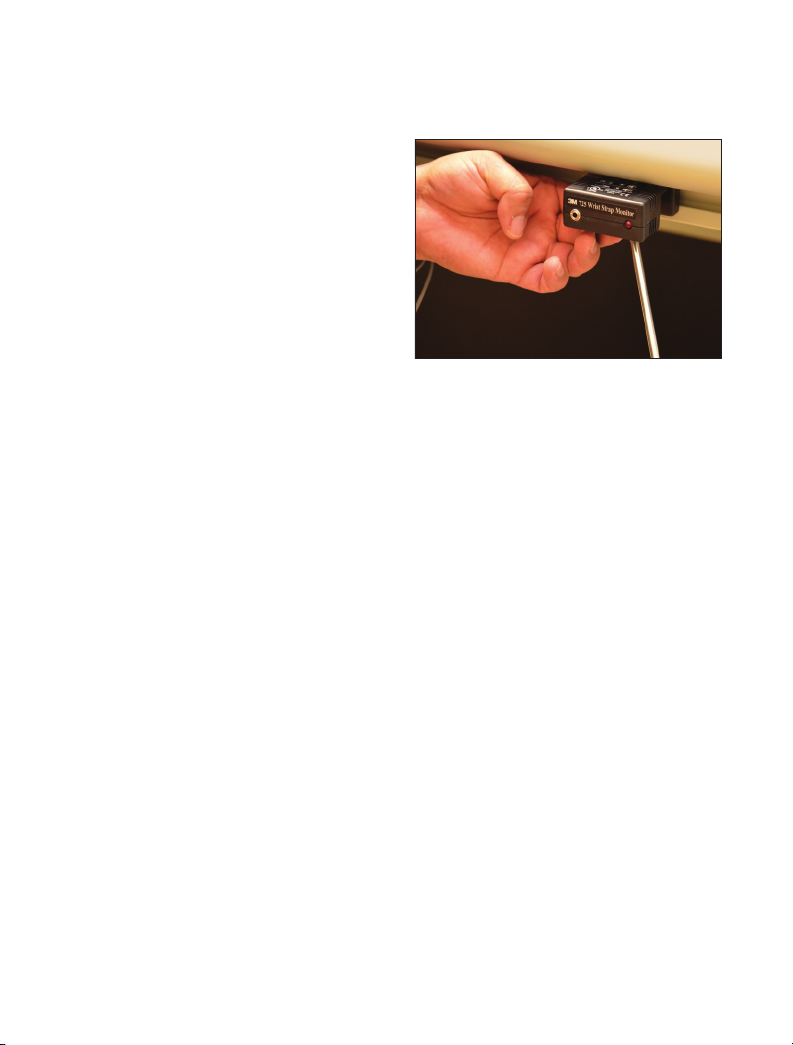

Figure 2

NOTICE

If you decide not to use the dual

conductor ground clip that is attached

to the monitor’s ground cord in the

way described in this user instruction

manual, observe the following

precaution: Attach each of the two wires

of the monitor’s ground cord to separate

ground bonding points. By attaching the

wires to the same ground but at different

physical locations, the monitor can

check for loose or lost connections.