6

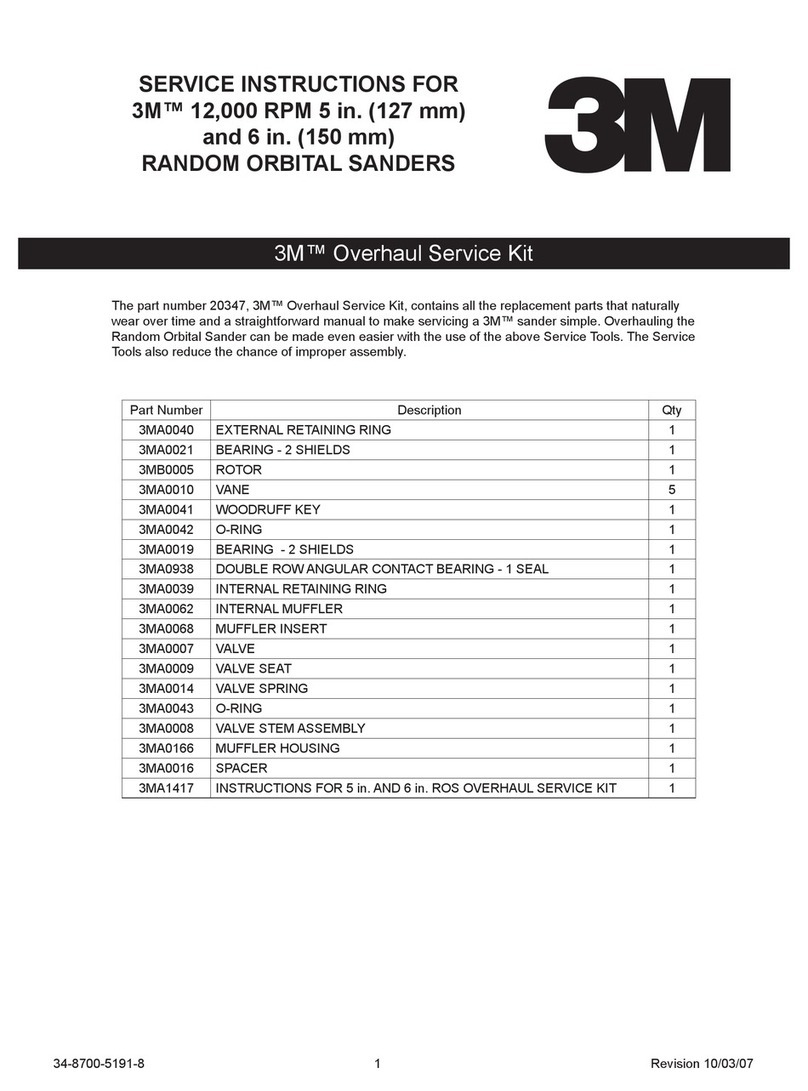

C. SPARE PARTS INFORMATION - continued

ITEM No. PART No. DESCRIPTION QTY

1 410320 Spring pin ( 3” x 20”) 1

2 22975A Valvelever 1

3 OV12 Snapring(OV-12) 1

4 20820 Valvepinsleeve 1

5 KS07 Oring(KS-7) 1

6 KS02 Oring(KS-2) 1

7 20823 Valve 1

8 25814 Valvespring 1

9 229013A Body 1

10 22952 Silencer 2

11 22953 Silencercap 1

12 130512 Screw (M5 x 12”) 1

13 3805 Washer(M5) 1

14 6000ZZ Ballbering(6000ZZ) 1

15 207083 U-baringcase 1

16 216031A Cylinderset 1set

16-1 216031 Cylinderset 1

16-2 KS05 O-ring(KS-5) 1

16-3 410308 Springpin(3”x8”) 2

16-4 410304 Springpin(3”x4”) 1

17 22621 Rotor 1

18 22622 Vane 8

19 22342 L-bearingcase 1

20 6300ZZ Ballbearing(6300ZZ) 1

21 22340 Shaft with head 1

22 510313 H/Rkey(13”x3”) 1

23 20913 Retainerbolt 1

24 6001DD Ballbearing(6001DD) 2

25 22309 18feltring 1

26 22308 Dustseal 1

27 22341 Pad retainer 1

28 OV28 Snapring(OV-28) 1

29 22907 Bodygasket 1

30 22951 Basering 1

31 22908 Dustpacking 1

32 150412 Screw (M4 x 12) 4

33 * 3”pad 1

* 3M™ Disc Pad 00-51111-55764-8

Special Tools for repair operation

ITEM No. PART No. DESCRIPTION QTY

1 ST005 6200bearingpunch 1

2 ST007 3 mm pin punch 1

3 ST008 945Ashaftbearingpuller 1

4 ST024 Bearing puller stand 1

5 ST502 Snap ring pliers 1