3

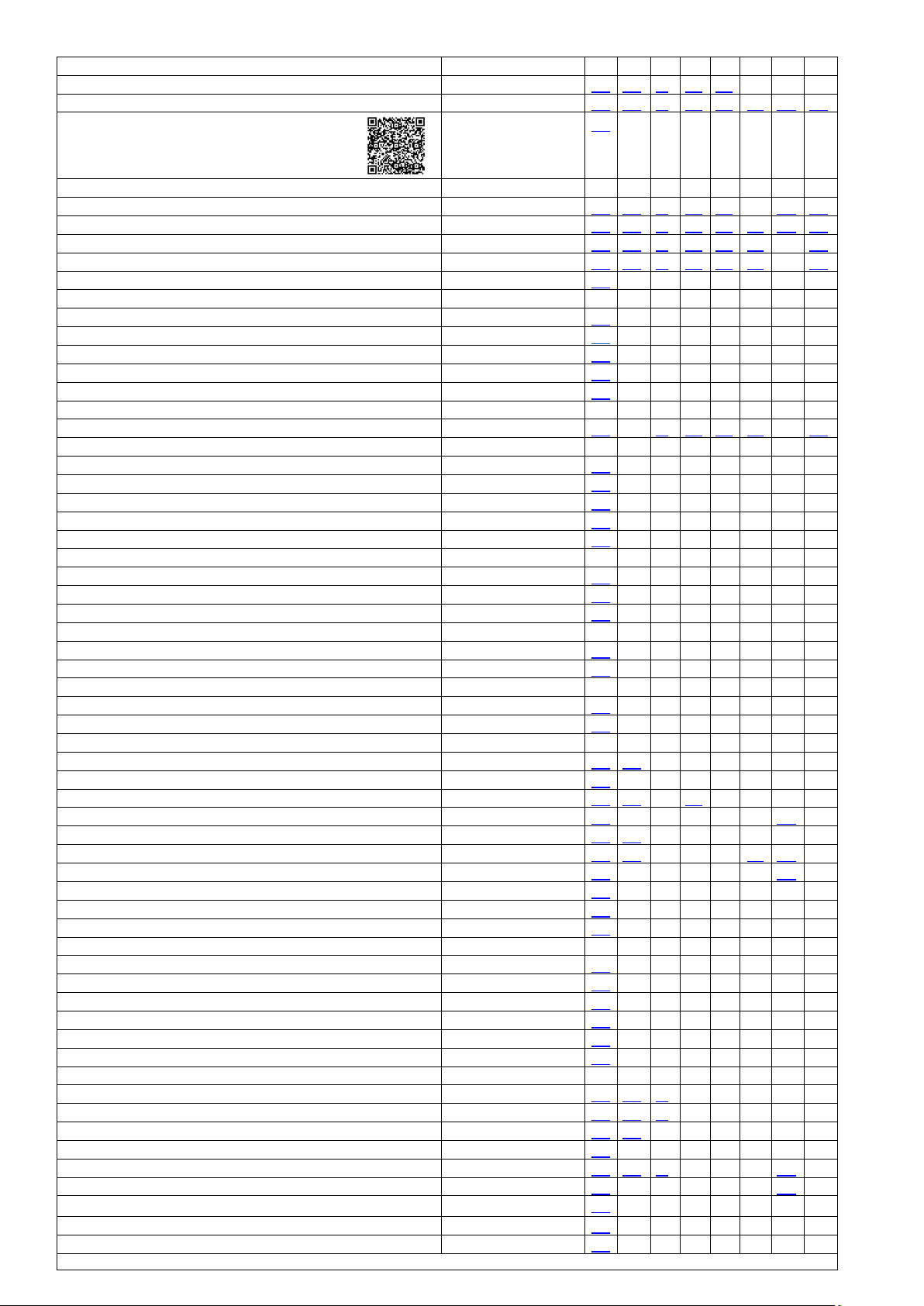

Table of contents

3ADW000803R0101 DCS880 H4T (Tosa) manual en a

Table of contents

DCS880 Drive Manuals..................................................................................................................................................2

Safety instructions 4

What this chapter contains..........................................................................................................................................4

To which products this chapter applies ....................................................................................................................4

Usage of warnings and notes......................................................................................................................................4

Installation and maintenance work ............................................................................................................................4

Grounding ...................................................................................................................................................................5

Printed circuit boards and fiber optic cables.......................................................................................................5

Mechanical installation .................................................................................................................................................6

Operation.........................................................................................................................................................................6

Introduction to this manual 8

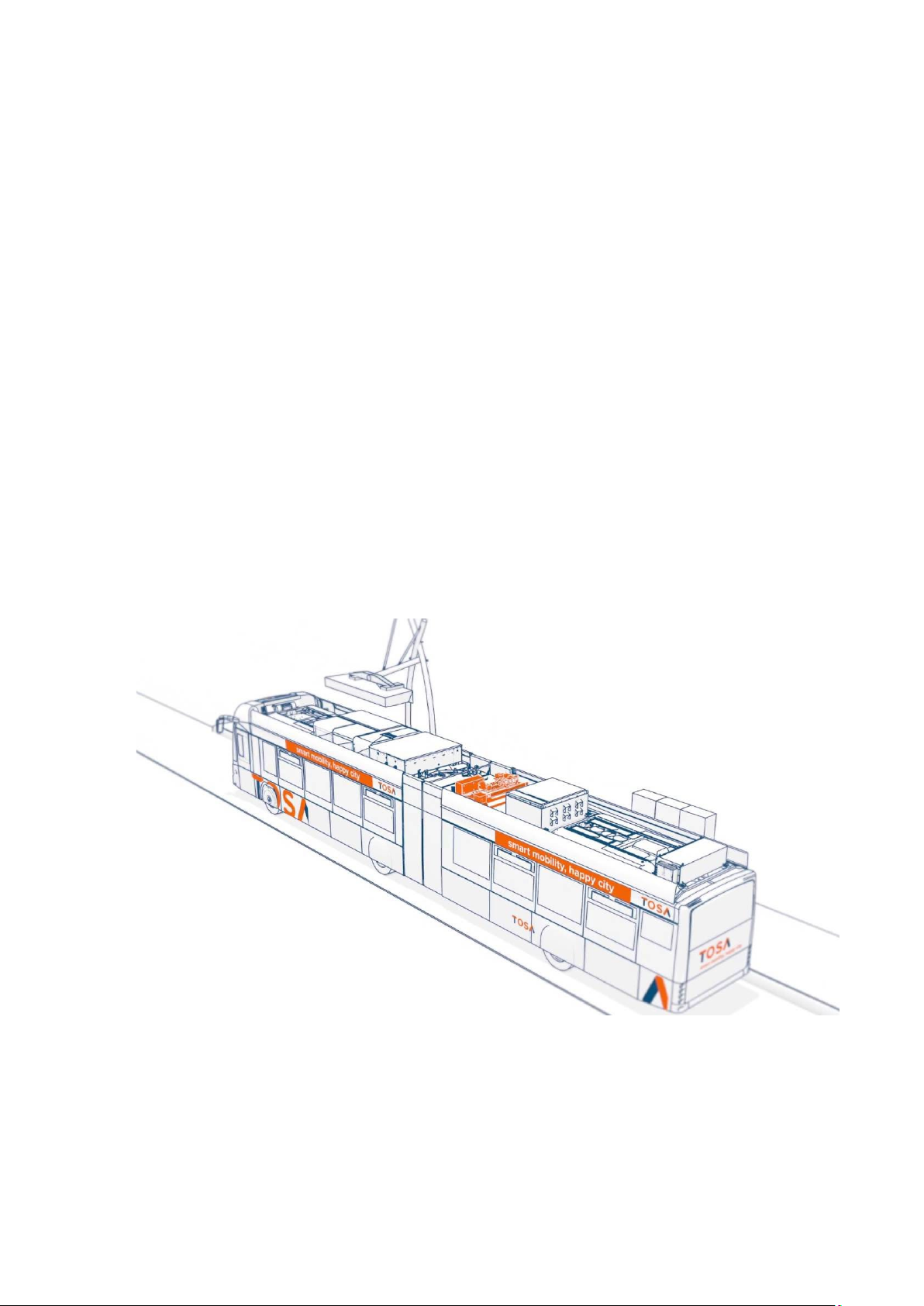

H4T....................................................................................................................................................................................8

Application ......................................................................................................................................................................8

Related documents........................................................................................................................................................8

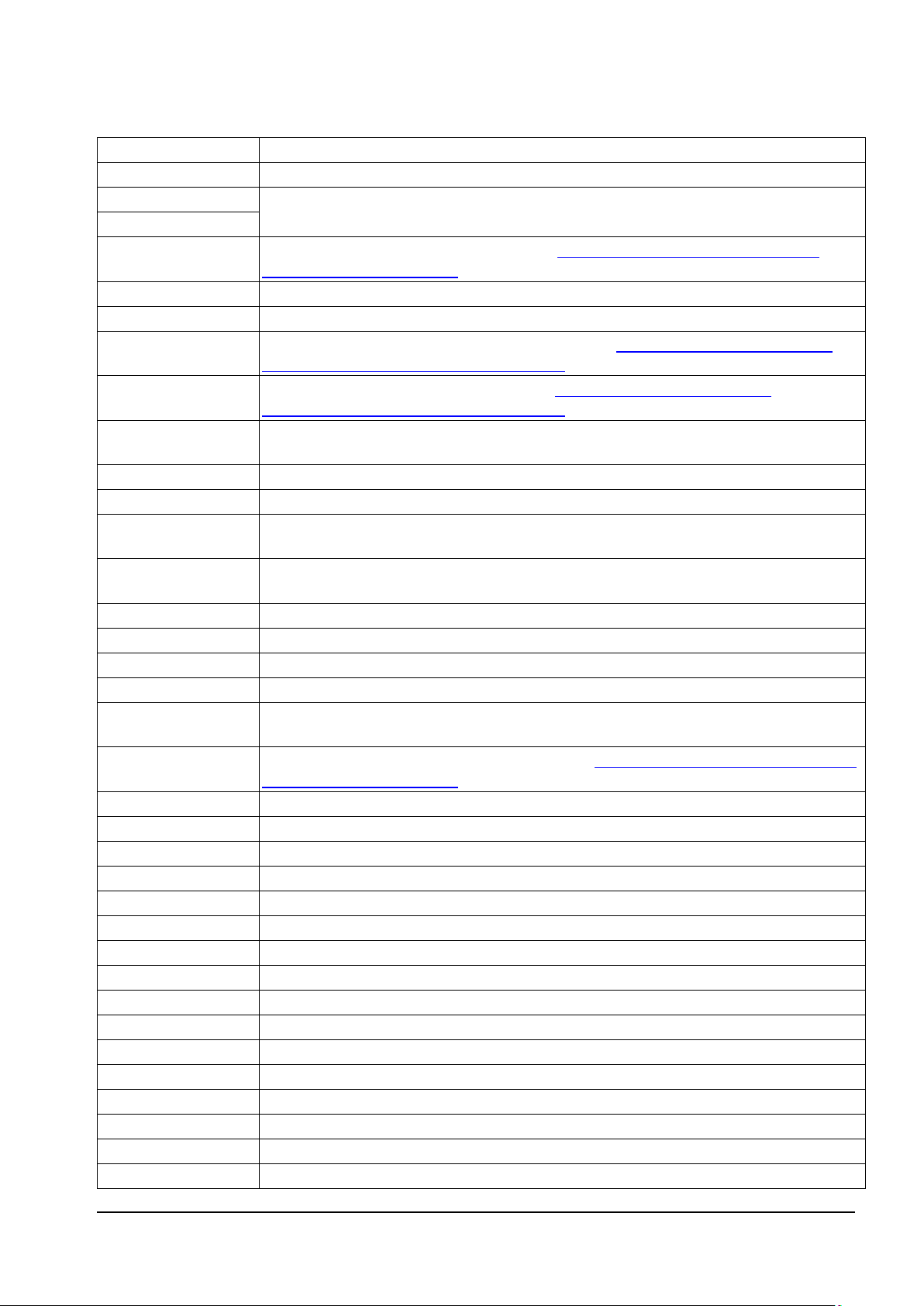

Terms and abbreviations..............................................................................................................................................9

Cybersecurity disclaimer ............................................................................................................................................ 11

H4T hardware 12

Type code ...................................................................................................................................................................... 12

Type code units size H4T........................................................................................................................................ 13

Main circuit and control..............................................................................................................................................14

Armature converter DCS880 H4T .........................................................................................................................14

Converters size H4T configuration ......................................................................................................................15

Mains power connection ........................................................................................................................................16

Cooling fans ..................................................................................................................................................................16

Fan assignment for DCS880..................................................................................................................................16

Fan cable sizes and tightening torque connected at the fan terminals .......................................................16

Cross-sectional areas - Tightening torques .......................................................................................................16

Current ratings - IEC non regenerative converters (S01)................................................................................. 17

2-Q units size H4T.................................................................................................................................................... 17

Circuit diagram ........................................................................................................................................................18

Galvanic isolation - T90, A92, F11, F90 .................................................................................................................19

Size H4T .................................................................................................................................................................... 20

Fuses and fuse holders IEC for converter size H4T........................................................................................... 21

H4T firmware 22

H4T service 23

Current ratings .............................................................................................................................................................23

Fault Tracing Thyristors 24

Units size H4T...........................................................................................................................................................24

Blown fuses...............................................................................................................................................................24

Exchange thyristors size H4T 25

Remove faulty thyristor modules .........................................................................................................................25

Install new thyristor modules................................................................................................................................32

Commissioning 33