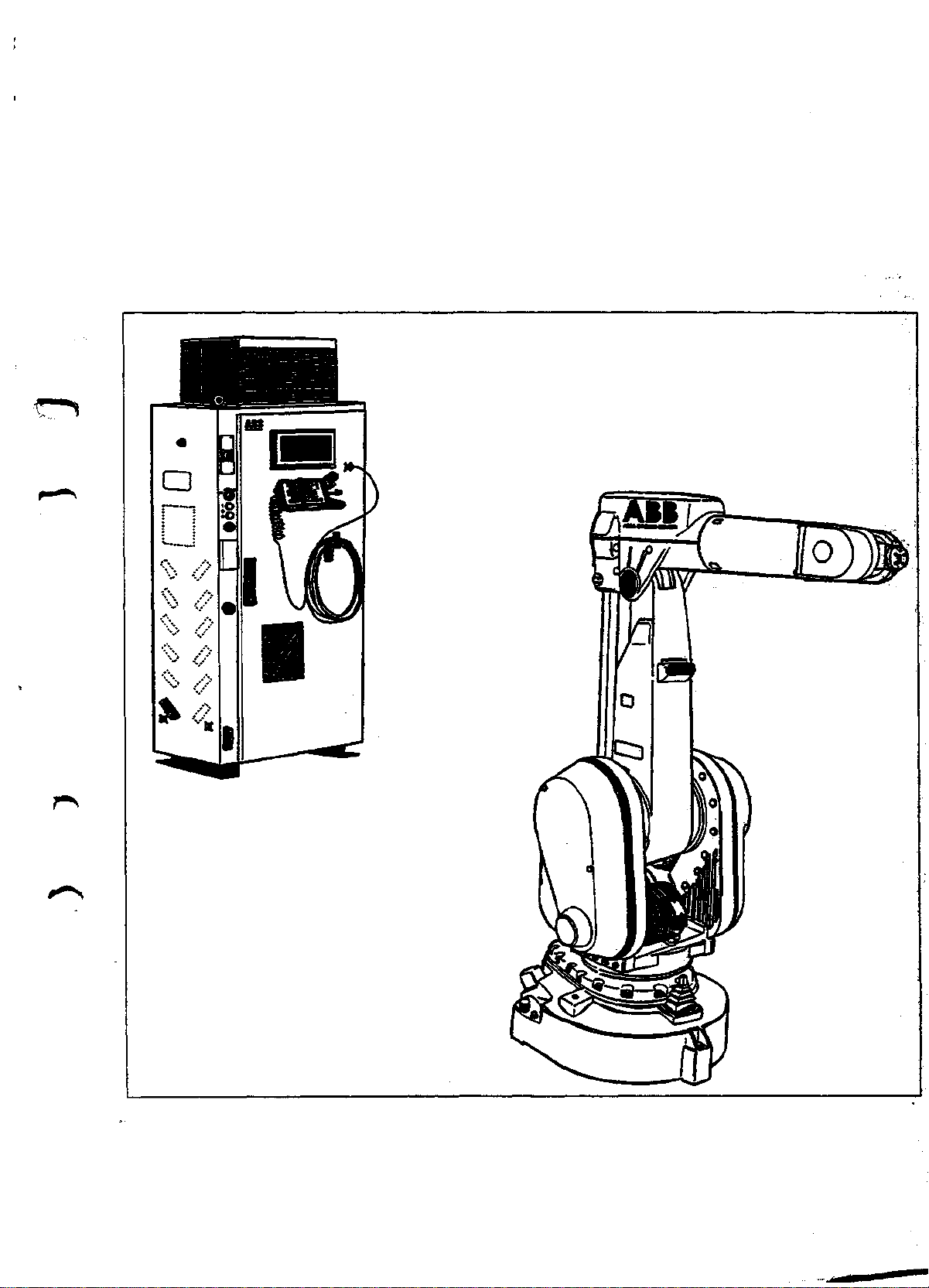

INTRODUCTION

1KB2000

isa six-axesrobotwitha largeworkvolumeandisprimarilyintendedforarc

weldingandglueing/sealing.IRB2000isalsosuitableforapplicationssuchas

assembly,waterjetcutting,lasercutting,materialhandlingandstudwelding.

Thehandlingcapacityis10kgandtheveryquickmovementsofthewristaxesare

otherimportantfeaturesfortheintendedapplications.

Tomakeitpossibletoadapttherobottovariousapplications,a rangeofperipheral

equipmentforvariousapplicationsisavailable.Theperipheralequipmentrange

includestoolexchangers,gripperholdersandseveraldifferentgripperunits.

Powerandairsupplyisavailableatthegrippers.

Description1KB2000