B1 copy starts here

B2 copy starts here

B3 copy starts here

8OVR-15, 27 AND 38 OUTDOOR VACUUM RECLOSER LOW VOLTAGE UNIT WITH SEL-751

—

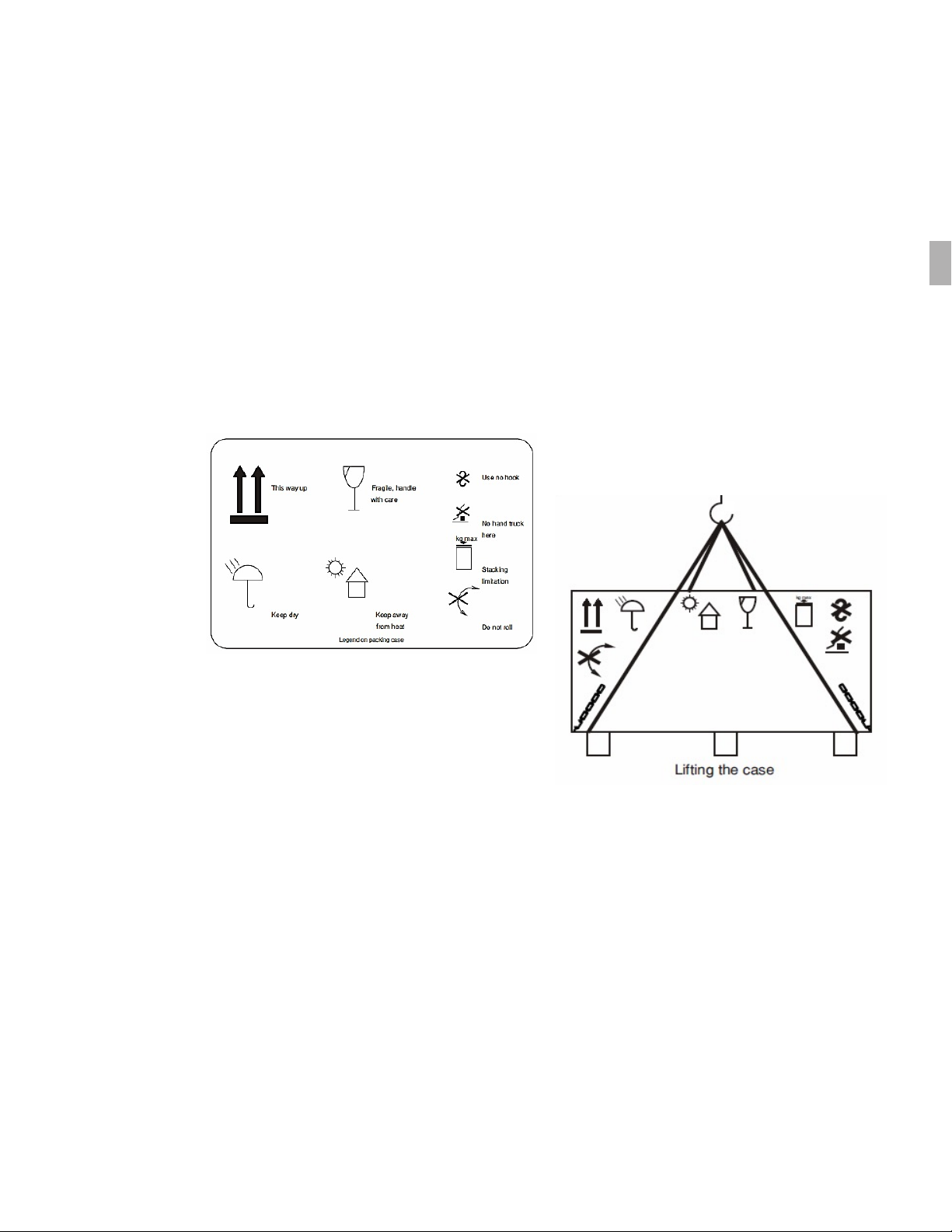

3 Receipt and storage prior to installation

3.1 Receipt of recloser

Each LV cabinet is assembled and tested at the

factory. Prior to shipment, the equipment is

thoroughly inspected to ensure a quality product

free from defects. If damage is noticed, call the

carrier at once for inspection, and request an

inspection report. Afterwards, file a formal claim

with the carrier, supported with the airway/

roadway bill.

Each delivery, on receipt, should be checked for:

• Shortages and discrepancies. (Check against

order and delivery documents.)

• Any transit damage or material losses.

Abnormality, if any, must be reported immediately

to ABB, forwarding agents and the insurance

company.

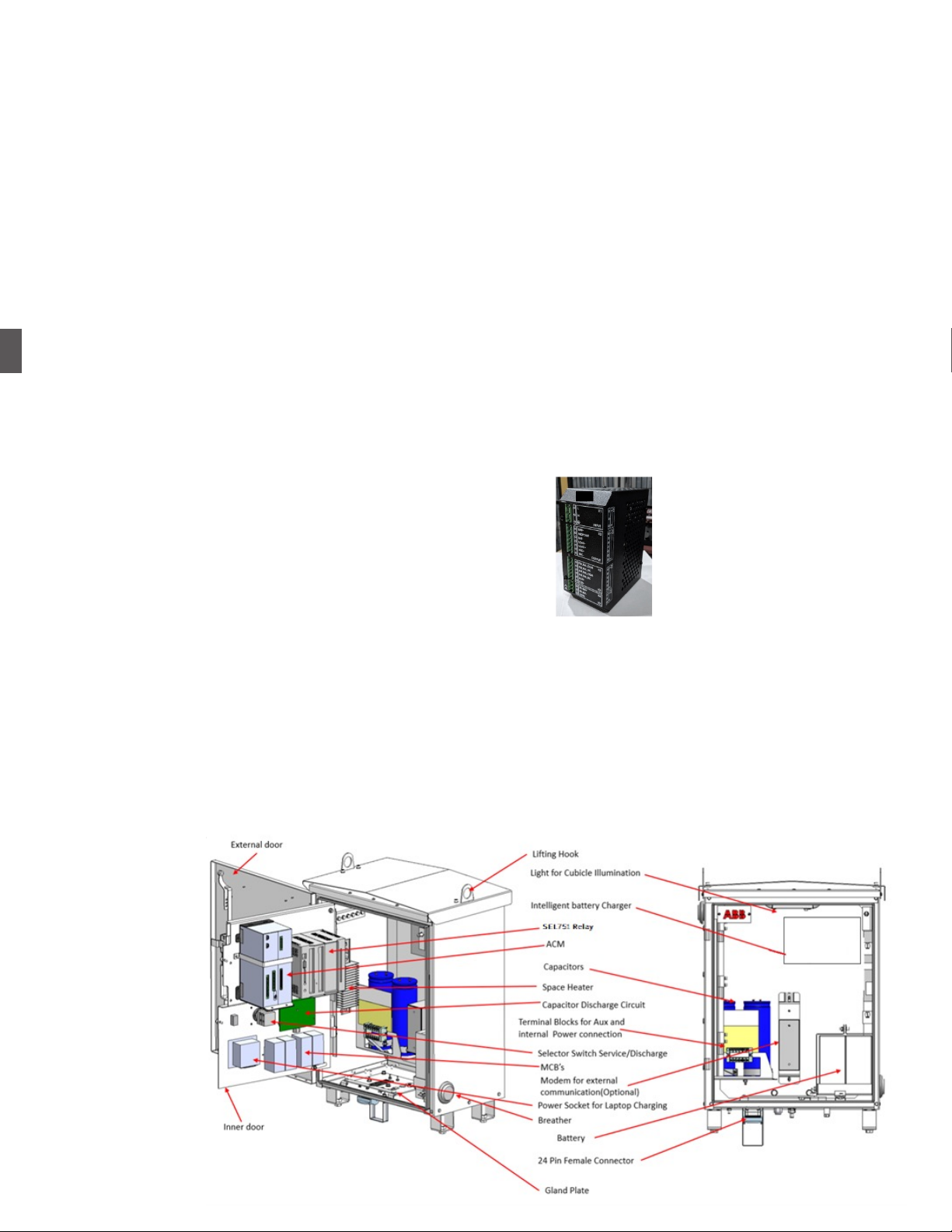

Instructions and literature packed with the LV unit

should be kept with the unit. Additional copies may

be obtained upon request from the local ABB sales

office. Following are the typical parts with which

reclosers are generally shipped from the factory.

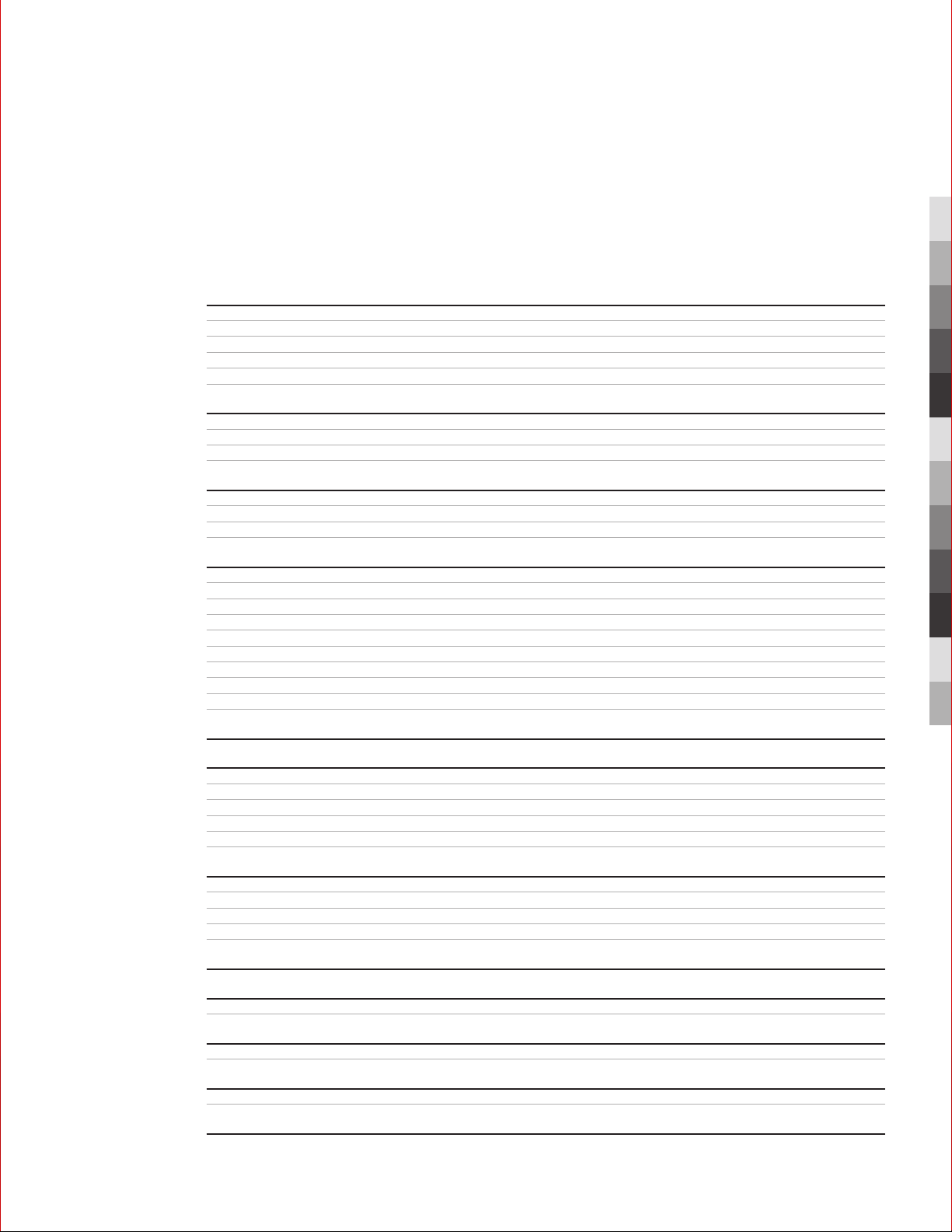

Default shipment Low voltage (LV)

control cabinet

Optional items

(only if ordered separately)

Mounting brackets

Auxiliary power cable

Any additional spares

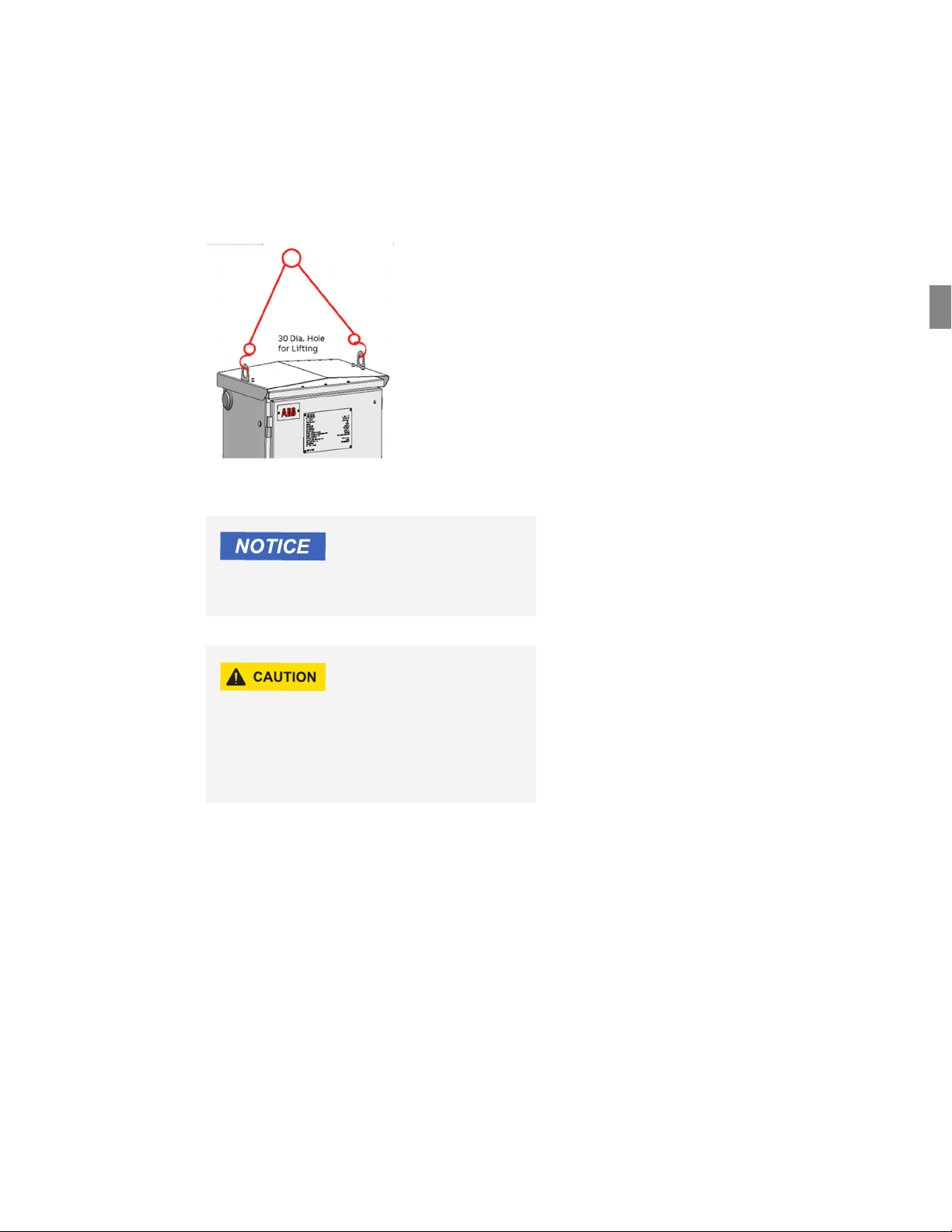

3.2 Storage of recloser LV unit

The LV cabinet with complete packing should

always be stored indoors to protect it from direct

sunlight, rain or snow. LV cabinets should be stored

in their original transport units, where they

are well protected from damage.

LV cabinets can be stored up to three months

from date of shipment from the factory. For longer

storage, the packing must be removed and the

recloser must be kept under controlled

environmental conditions.

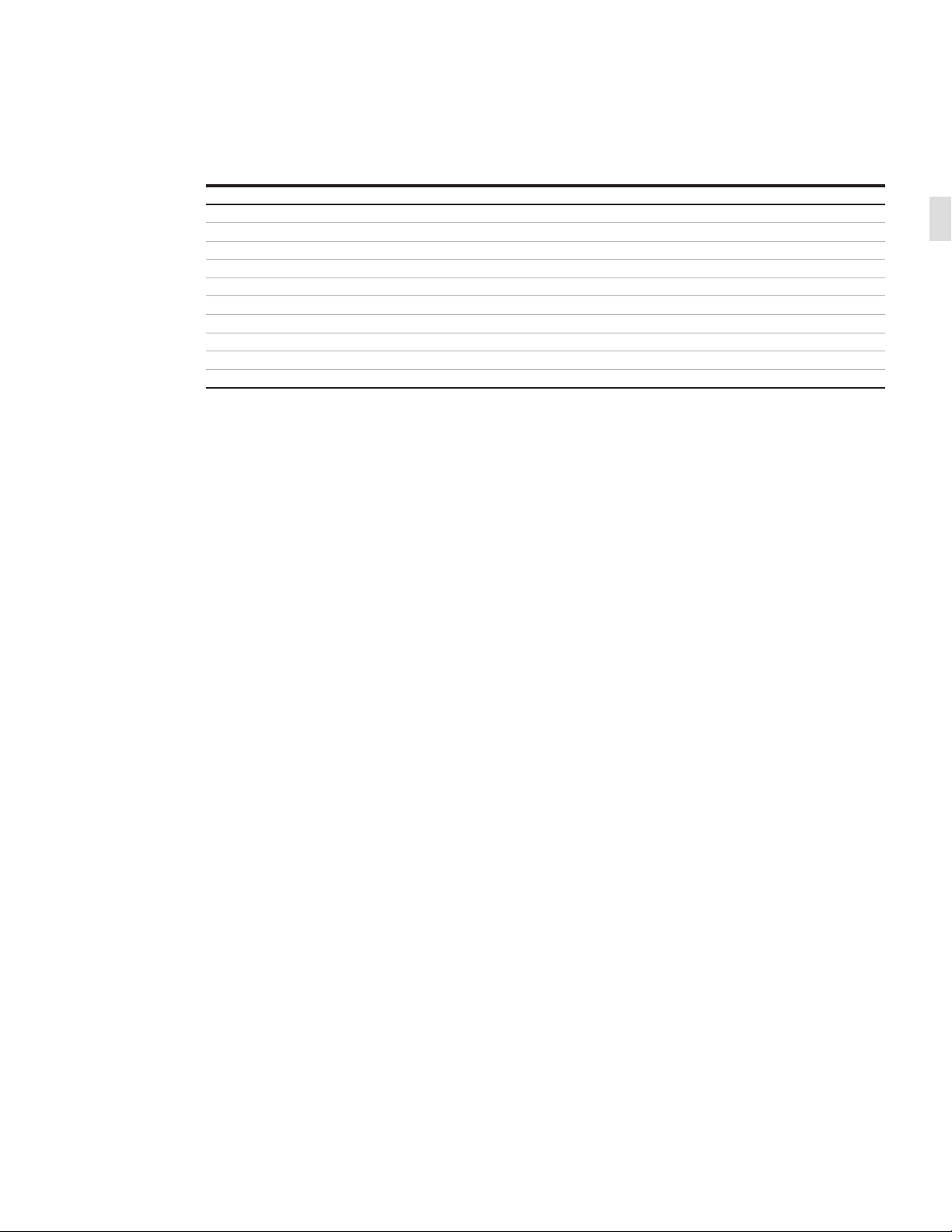

We define storage in controlled conditions

as a location with:

• Leak-proof roof

• Solid, flat ground

• Relative humidity less than 50%

•

• The heating elements must be connected to the

electric supply to protect the control equipment

from corrosion or freezing damage.

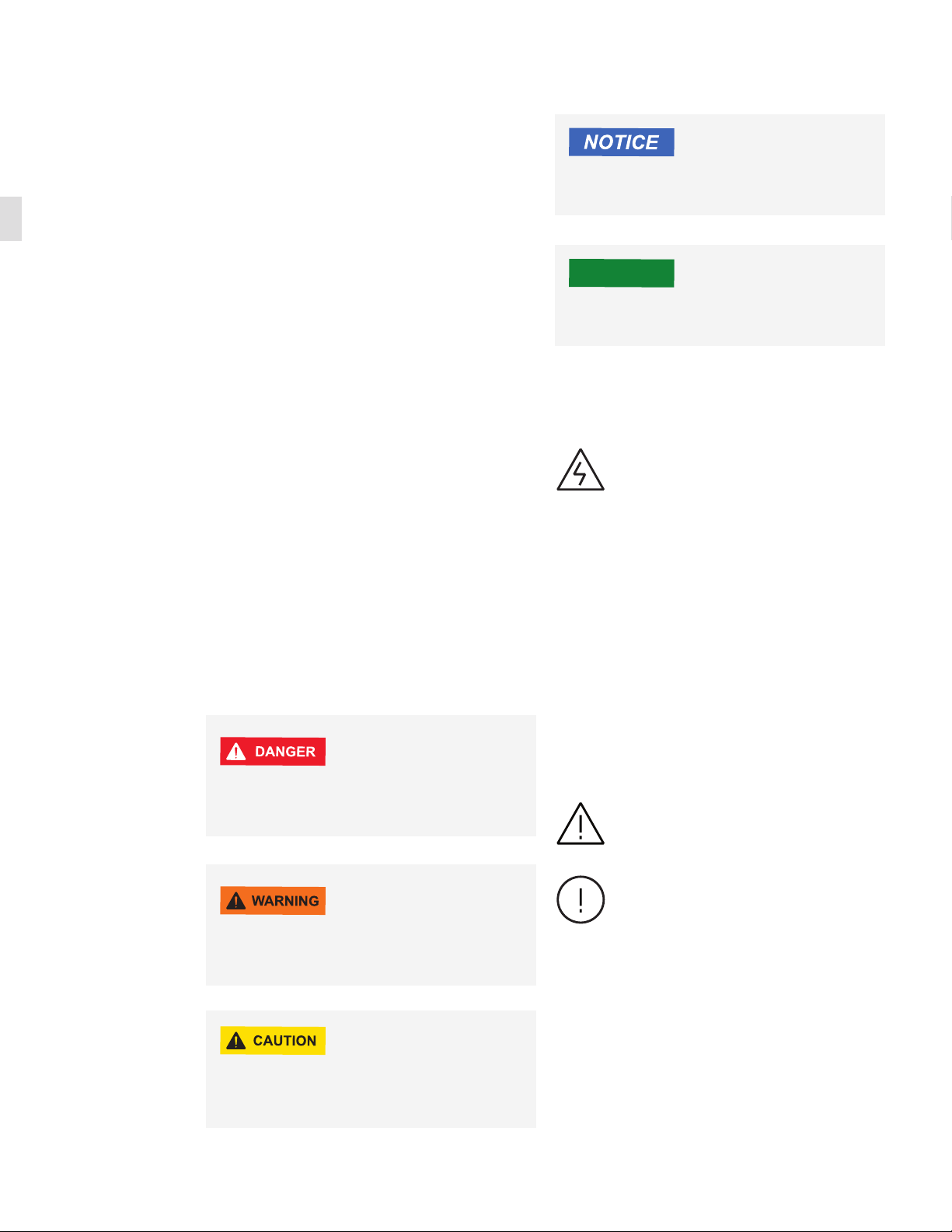

IMPORTANT

The LV cabinet must be stored in the upright

position to avoid moisture accumulation.

Recommended storage temperature range

The LV control cabinet has rechargeable

batteries inside. A periodic check of battery

voltage (24 V) and periodic charging of the

batteries (typically every three months) may

be required in case of prolonged storage.

For the batteries in your control cabinet,

refer to technical documentation of the

respective battery manufacturer. In addition,

refer to the “inspection and maintenance”

section of this manual for more information.

If the LV cabinet is not placed in service

immediately, it is essential that proper care be

exercised in handling and storage to ensure

good operating condition in the future. Please

consult ABB if the recloser will be in storage for

an extended period of time before installation.

03