Analog Annunciator Unit

Product Guide

SACO 16 A3

1MRS750405-MBG

4

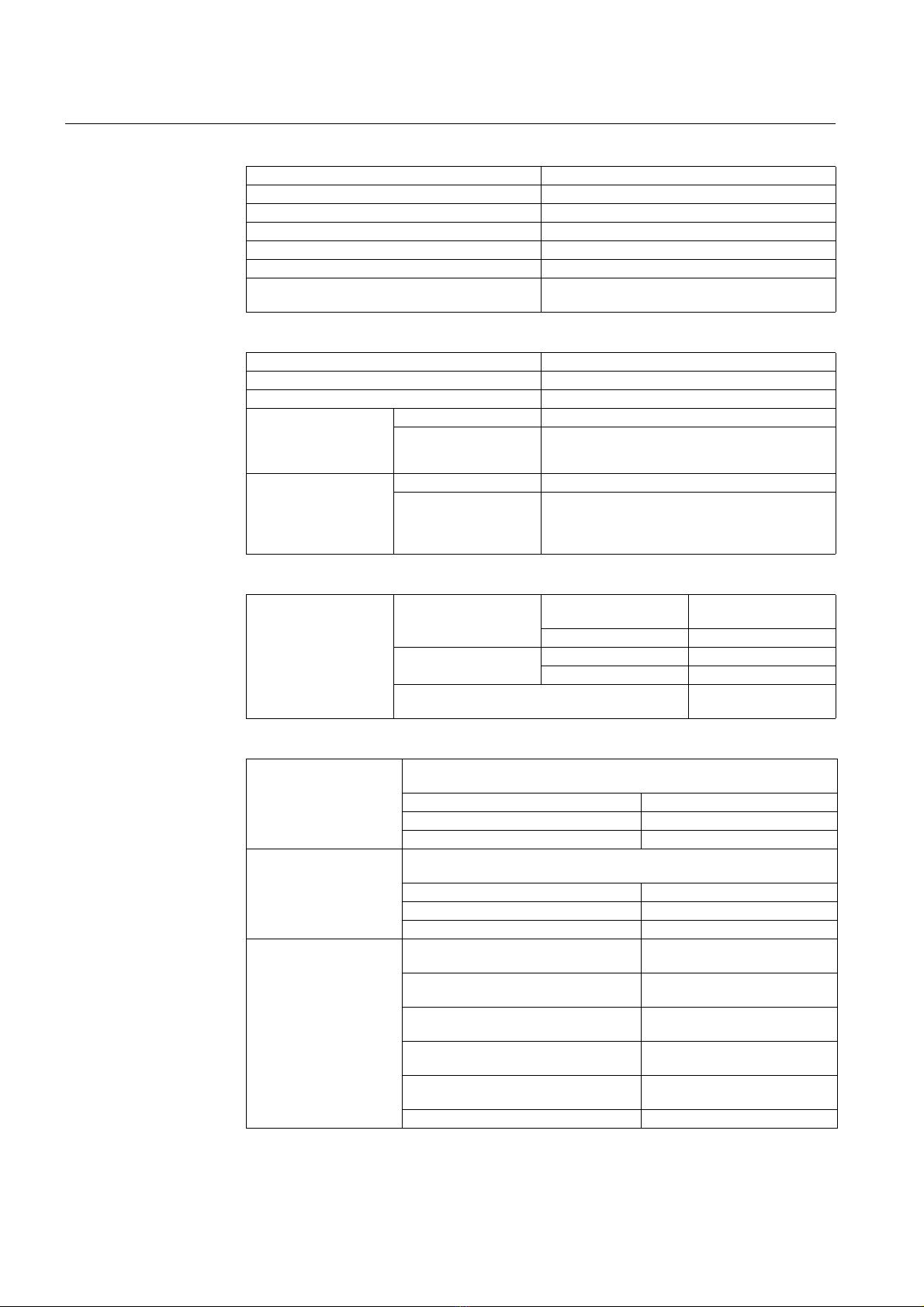

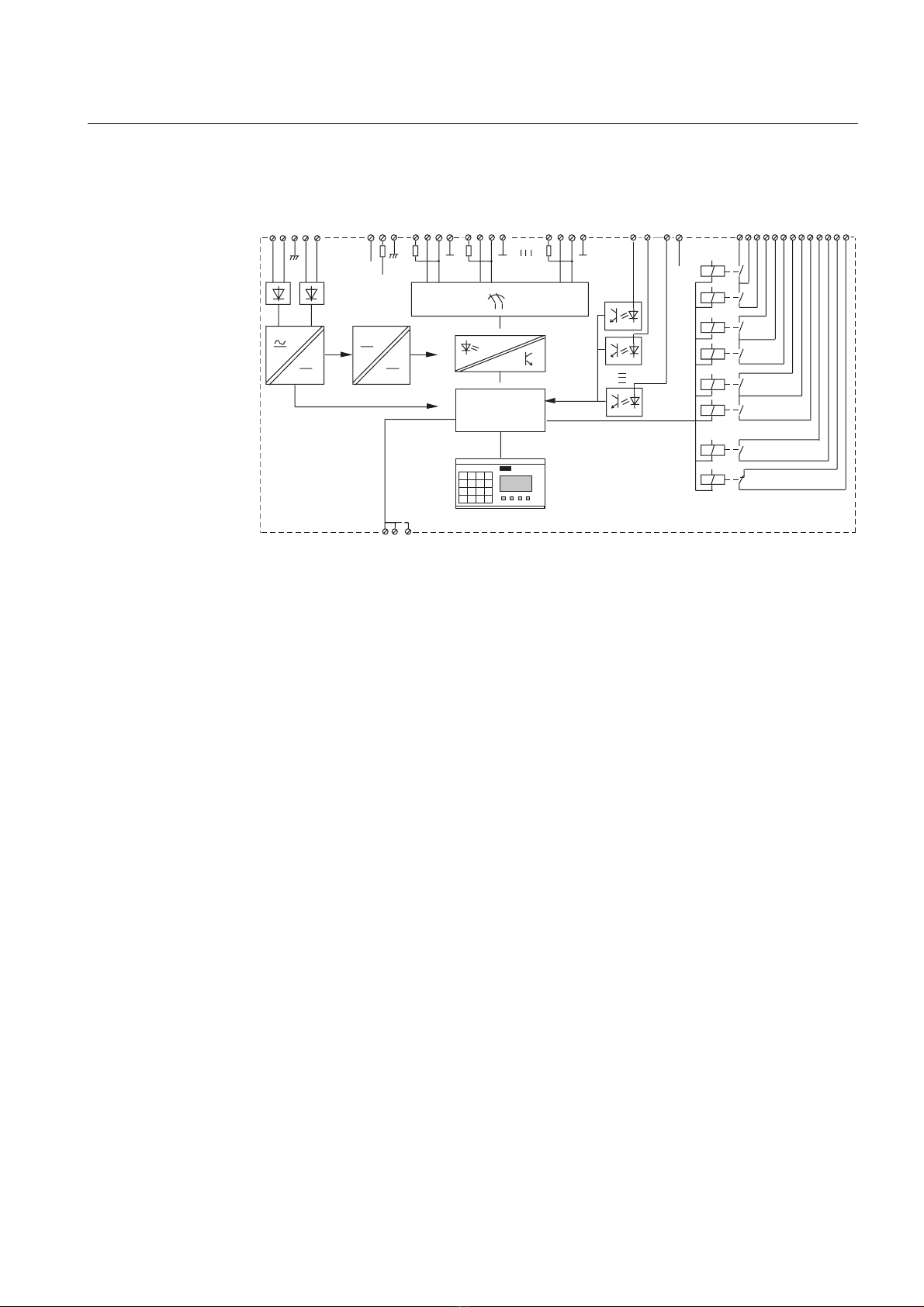

Design The channels of the analog annunciator unit

measure voltage, current and resistance via

sensors or transducers in the process. Further,

contact signals can be wired to the input

channels. The signal type can be separately

set for each channel.

The channel inputs are galvanically separated

from earth and from the digital part of the

annunciator electronics, but the channels are

galvanically interconnected. This arrange-

ment facilitates the supervision and the indi-

cation of earth faults in the transducers or the

transducer wiring.

The alarm channel inputs accept the follow-

ing signal levels: 0…5 mA, 1…5 mA,

0…20 mA and 4…20 mA, 0…1 V, 0…5 V,

1…5 V, 0…10 V and 2…10 V. The following

standard sensors types can be used for tem-

perature measurement: Pt 100, Pt 250,

Pt 1000, Ni 100, Ni 120, Ni 250, Ni 1000.

Further, any Pt or Ni signal within the range

65…1000 Ω, potentiometric signal within the

range 0…200 Ω, 0…500 Ω, 0…1 kΩ,

0…2 kΩ, 0…2.5 kΩ, 0…10 kΩcan be used

and scaled. For the resistance sensors two- or

three-wire connection can be used.

In addition, the input channels can be acti-

vated by a making or a breaking contact.

The values measured can be shown as numer-

ical values, bar graphs or curves on the dot

matrix display on the front panel. The same

information can also be read by a superior

system via the serial interface.

The content of the event sequence register

can be read on the display. The total system

can be configured by means of the push-but-

tons and the display on the front panel, or via

the serial interface.

When a measured signal exceeds or falls

below the set start value of the channel a

visual indication is obtained on the alarm

panel. At the same time the acoustic alarm

output contact picks up and, if configured, a

group alarm relay operates. The event thus

generated is stored in the event register.

Any information generated in the annunciator

unit can be read by a hierarchically superior

system via the serial interface.

Data communication

The relay is provided with a serial interface

on the rear panel. By means of a bus connec-

tion module type SPA-ZC 17/S or SPA-

ZC 21/S the relay can be connected to the

fibre-optic SPA bus. The bus connection

module type SPA-ZC 21/S is powered from

the host relay, whereas the bus connection

module SPA-ZC 17/S is provided with a

built-in power unit, which can be fed from an

external secured power source. The relay

communicates with higher-level data acquisi-

tion and control systems over the SPA bus.

Self-supervision

The annunciator incorporates a sophisticated

self-supervision system which increases the

availability of the device and the reliability of

the system. The self-supervision system con-

tinuously monitors the hardware and the soft-

ware of the equipment. The system also

supervises the operation of the auxiliary sup-

ply module and the electronics’ voltages gen-

erated by the module.

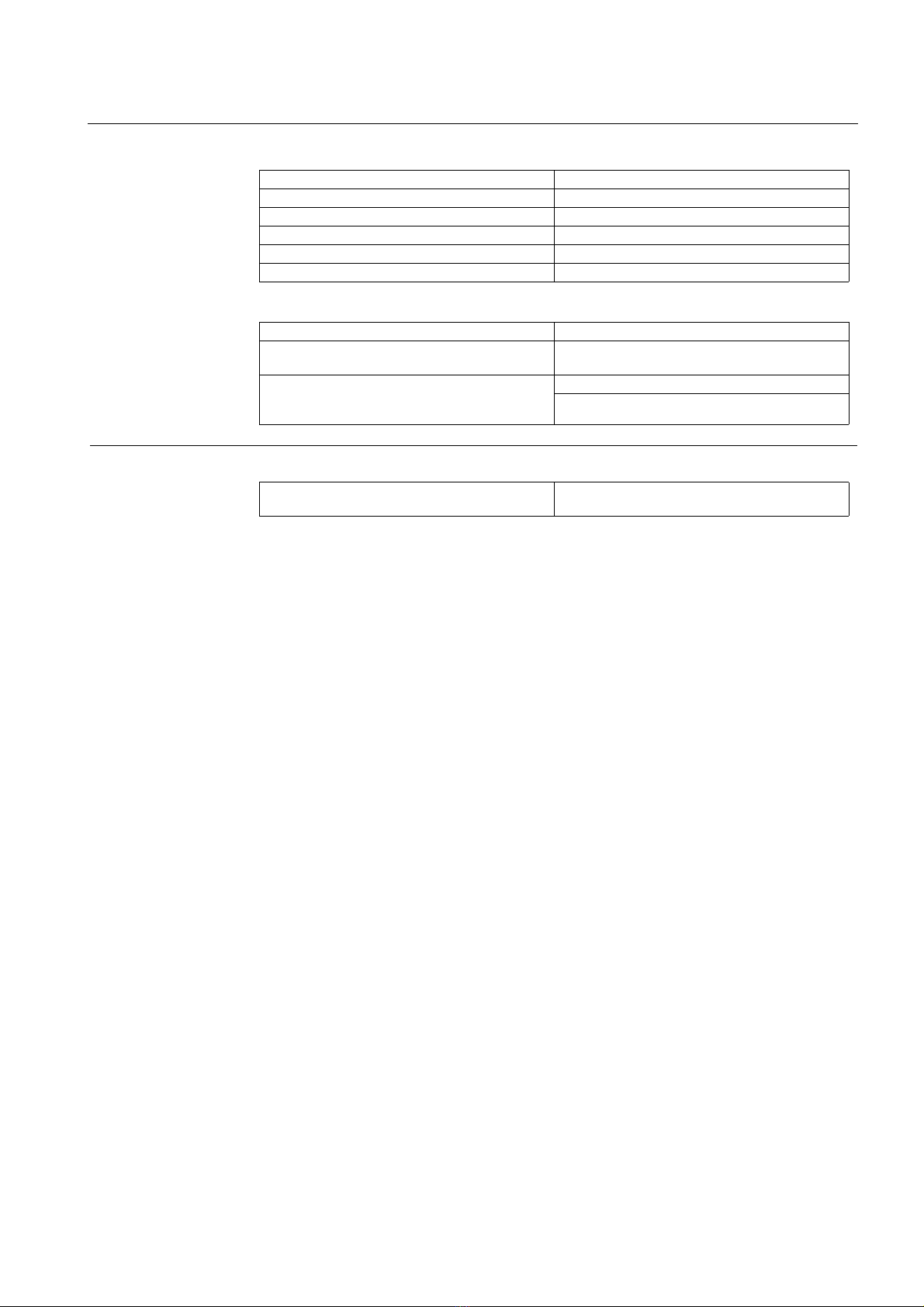

Auxiliary supply voltage

The auxiliary supply of the relay is obtained

from an internal plug-in type power supply

module. Two auxiliary power module ver-

sions are available: type SPGU 240A1 for the

supply voltage range 80…265 V ac/dc and

type SPGU 48B2 for the supply voltage range

18…80 V dc. The power supply module

forms the internal voltages required by the

annunciator.