We herewith confirm that this Operation Manual has been drawn up orientated towards the Product Liability Law 1/1/90 as well as to

the „European Machinery Directives“.

We reserve all rights in this document and in the information contained herein.

Reproduction, use or disclosure to third parties without express authority by ABB Turbo Systems Ltd is strictly forbidden.

©Copyright by ABB TURBO SYSTEMS Ltd 2004

Design and specifications are subject to change without notice.

Printed on naturally white paper, bleached free from chlorine and environmentally acceptable.

The CD is made of polycarbonate and contains in addition aluminium, lacquer, dye stuffs and materials of the adhesive label. The CD-cover is made of

recycled cardboard.

These materials may be disposed with the domestic wastes or at a specialised collecting centre.

ABB Turbo Systems AG

Bruggerstrasse 71a

CH-5401 Baden

Switzerland

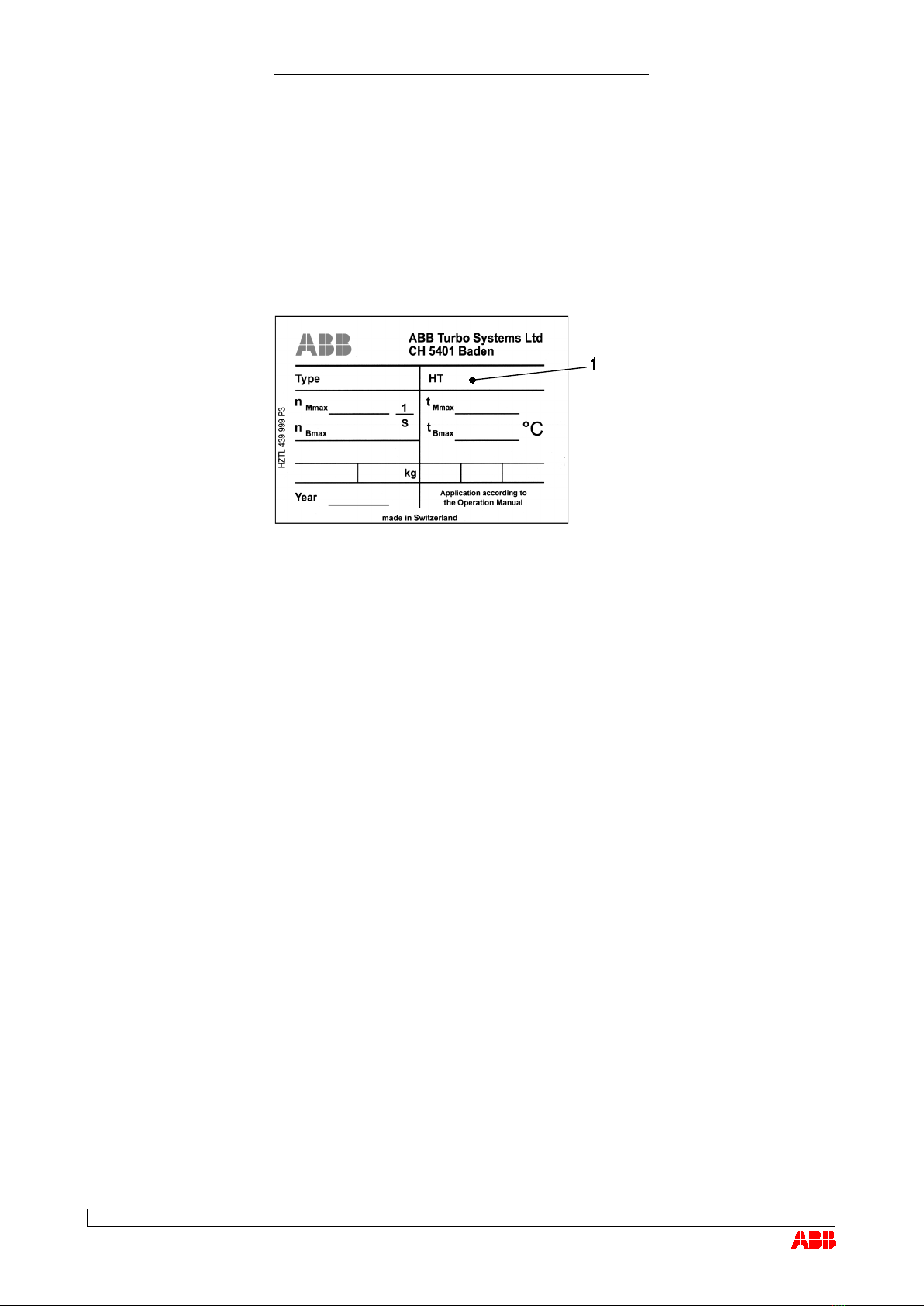

Operating condition and replacement intervals

The operational limits for the turbocharger nBmax, tBmax, nMmax, tMmax, inspection- and replacement intervals for the compon-

ents concerned on the rating plate are valid for the operational mode and compressor inlet condition, which has been agreed upon

between the engine builder and ABB.

Note: Replacement intervals of components depends on the load profile, turbine inlet temperature, suction air temperature and

turbocharger speed. In case the operation conditions differs significantly from what is considered to be normal for the cur-

rent application, it is recommended to contact ABB for a re-calculation of replacement intervals. Frequent load alterations,

high temperatures and high speed lower the life of components.

Unless otherwise agreed, the application limits nMmax, tMmax are valid for the test operation for a limited time.