5

1 Summary

1.1 General

The vacuum circuit-breakers of type VD4 on with-

drawable parts for 36 kV or 40.5 kV rated voltage

are intended for indoor installation in air-insulated

switchgear systems. Their switching capacity

is sufficient to handle any conditions arising

from switching of equipment and system

components under normal operating and fault

conditions, particularly short-circuits, within the

parameters of their technical data.

Vacuum circuit-breakers have particular ad-

switching frequency in the working current range

and/or where a certain number of short-circuit

breaking operations are expected. Type VD4

vacuum circuit-breakers are suitable for auto-

reclosing, and have exceptionally high operating

reliability and long life.

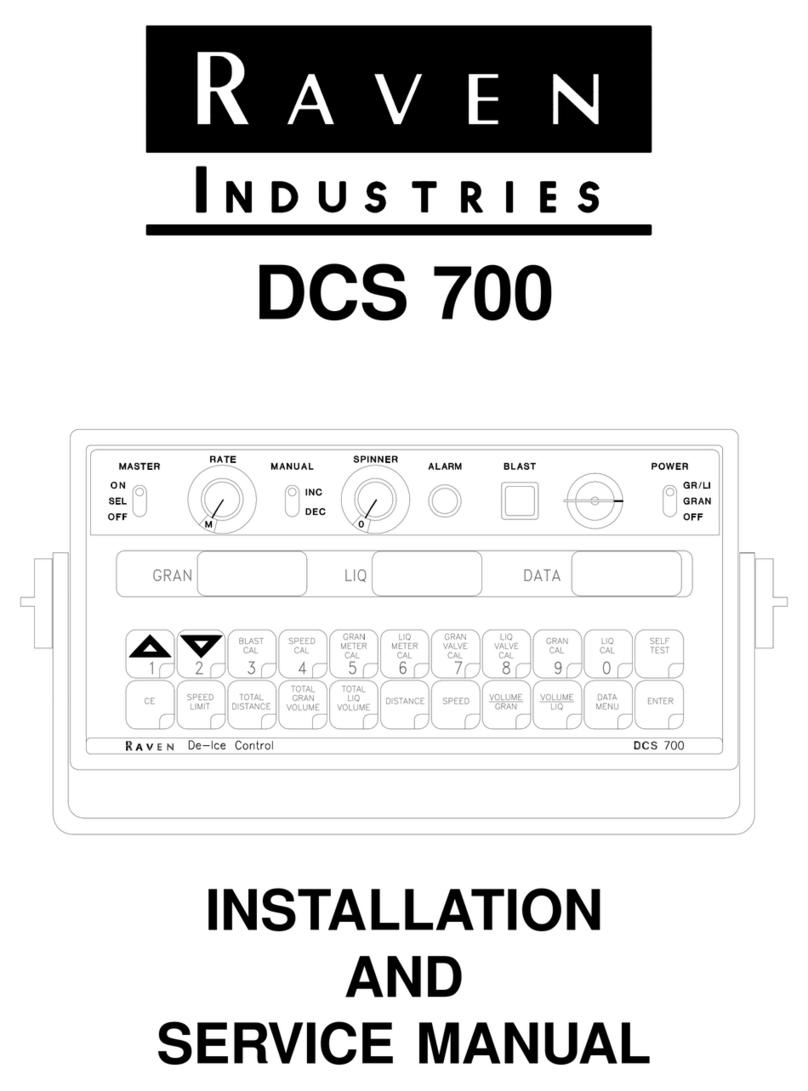

The vacuum circuit-breakers designed in column

form, are supplied as withdrawable modules. Their

basic structure is shown in figures 3/1,3/2,3/7 and

3/8.

1.2 Standards and specifications

1.2.1 Switchgear manufacture

The switchgear complies with the following

specifications in accordance with GB, IEC and

the relevant DIN VDE publications respectively.

●GB/T 11022, IEC 60694 and DIN VDE 0670

part 100, "Common specifications for high-

voltage switchgear and controlgear standards".

●GB 1984 and IEC 62271-100, "High-voltage

alternating-current circuit-breakers".

1.2.2 Installation and operation

The relevant specifications are to be taken into

account during installation and operation,

particularly:

●IEC 61936, Electrical devices with rated

voltage above AC 1 kV

●DIN VDE 0101, Power installations exceeding

AC 1 kV

●DIN VDE 0105, operation of electrical

installations

●DIN VDE 0141, earthing systems for special

power installations with rated voltages over

1 kV

●Accident prevention regulations issued by the

appropriate professional bodies or comparable

organisations.

In Germany, these comprise the following

safety regulations:

- Health and Safety at Work Standard VBG 1

- Health and Safety at Work Standard VBG 4

●Safety guidelines for auxiliary and operating

materials

●Order related details provided by

ABB Xiamen Switchgear Co.,Ltd.

1.3 Operating conditions

1.3.1 Normal operating conditions

Design to GB/T 11022, "Common specification

for high-voltage switchgear and controlgear

standards", IEC publication 60694, VDE 0670

part 100, with the following limit values:

●Ambient temperature:

-

Maximum +40˚C

-

Highest mean value measured

in 24 hours +35˚C

-

Minimum (according to "minus

5 indoor class") -15˚C

●Humidity

-

Highest mean value of relative humidity

measured over 24 hours 95%

-

Highest mean value of vapour pressure

measured over 24 hours 2.2kPa

-

Highest mean value of relative humidity

measured over 1 month 90%

-

Highest mean value of vapour pressure

measured over 1 month 1.8kPa

●Maximum site altitude:

1000m above sea level

1.3.2 Special operating conditions

Special operating conditions are to be agreed

on by the manufacturer and user. The

manufacturer must be consulted in advance about

each special operating condition:

●Site altitude over 1000 m:

-

Allow for the reduction in the dielectric

strength of the air.

●Increased ambient temperature:

-

Current carrying capacity is reduced.

-

Provide additional ventilation for heat

dissipation.

●Climate:

-

Avoid the risk of corrosion or other damage

in areas:

○with high humidity and/or

○with major rapid temperature fluctuations.

-

Implement preventive measures (e.g.

electric heaters) to preclude condensation

phenomena.