11.

Connection of the communication and control signals

12.

Commissioning

PVI-3.0_3.6_4.2-TL-OUTD-W-Quick Installation Guide EN-RevA

EFFECTIVE 2014-04-02

© Copyright 2014 ABB. All Rights Reserved.

9.

Line cable and protection devices

10.

Output connection (AC)

14.

Instruments

15.

Characteristics and technical data

13.

To protect the AC connection line of the inverter, we recommend installing a device for protection against over current and leakage with the following characteristics:

Type Automatic circuit breaker with differential thermal magnetic protection

Nominal Voltage 230 Vac

Nominal Current 20 A 25 A

Magnetic protection characteristic B/C

Number of poles 2

Type of differential protection A/AC

Differential sensitivity 300 mA

ABB declares that the ABB transformerless inverters, in terms of their construction, do not inject continuous ground fault currents and therefore there is no

due to high impedance of the line that connects the inverter to the power supply point.

2) Maximum length of the line conductor (mt)

4 mm² 19 m 16 m 14 m

6 mm² 29 m 24 m 21 m

10 mm² 48 m 41 m 35 m

16 mm² 77 m 65 m 56 m

The values are calculated in nominal power conditions, taking into account: 1. a power loss of not more than 1% along the line. 2. copper cable, with HEPR rubber insulation, laid in free air

Contact us

inverter has been correctly disconnected

- Remove the protective cap on the hole

19

used to pass the AC cable into the inverter.

-Insert an M32 cable gland (or compatible - hole diameter 33.8 mm) in the hole to be used for the AC output cable

19

- Strip 10 mm of sheathing from the AC grid connection cables

- Plug the AC line cable into the inverter, passing it through the previously installed cable gland

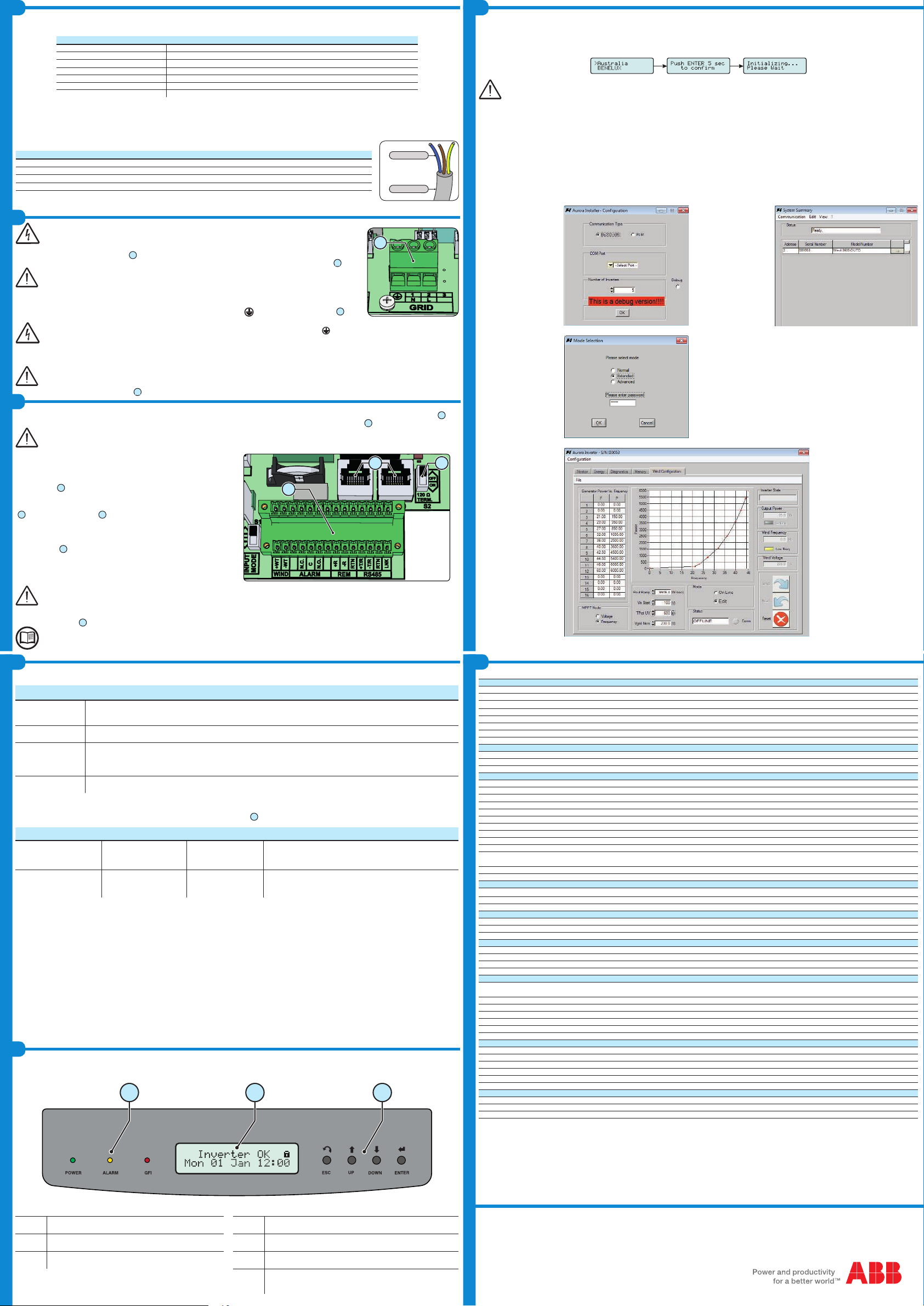

- Connect the protective earth (yellow-green) cable to the contact labelled with the symbol on the terminal block

10

section of the conductor for the maximum ground fault current that the generating system might experience

- Connect the neutral cable (normally blue) to the terminal labelled with the letter N

- Connect the phase cable to the terminal labelled with the letter L

Once the connection to the terminal board

10

Each cable which must be connected to the connectors of the communication and control signals must pass through one of the two service cable glands

20

.

An M20 cable gland (or compatible – hole diameter 20.3 mm) must be inserted in one of two of the service cable glands holes

20

.

Connection of the tachometer signal

The tachometer signal allows the 7200-WIND-INTERFACE-EU to drive the inver-

ter. It is therefore necessary to connect up the two cables from the 7200-WIND-

INTERFACE-EU ( and ) to the tachometer signal

terminal block

13

in correspondence with terminals and .

14

and by the terminal block

13

) must necessarily be connected to the

7200-WIND-INTERFACE-EU. For further details on connection of the RS485

line please see the 7200-WIND-INTERFACE-EU manual.

Terminal block

13

SET

TINGS > Alarm

that can be set are: Production and Alarm.

to the DC input voltage)

The REM terminal block

13

manual

The inverter commissioning procedure is as follows:

- Close the external switches: If the input voltage is greater than the minimum starting voltage, the inverter will start up.

- -

Select.” functionality will be blocked, and any subsequent changes can only be made using a password provided on request by ABB

Loading the Power Curve of eolic generator

not yet been loaded into the inverter. Thus, before connecting the inverter into the power grid, you must load the curve using the Aurora Installer software.

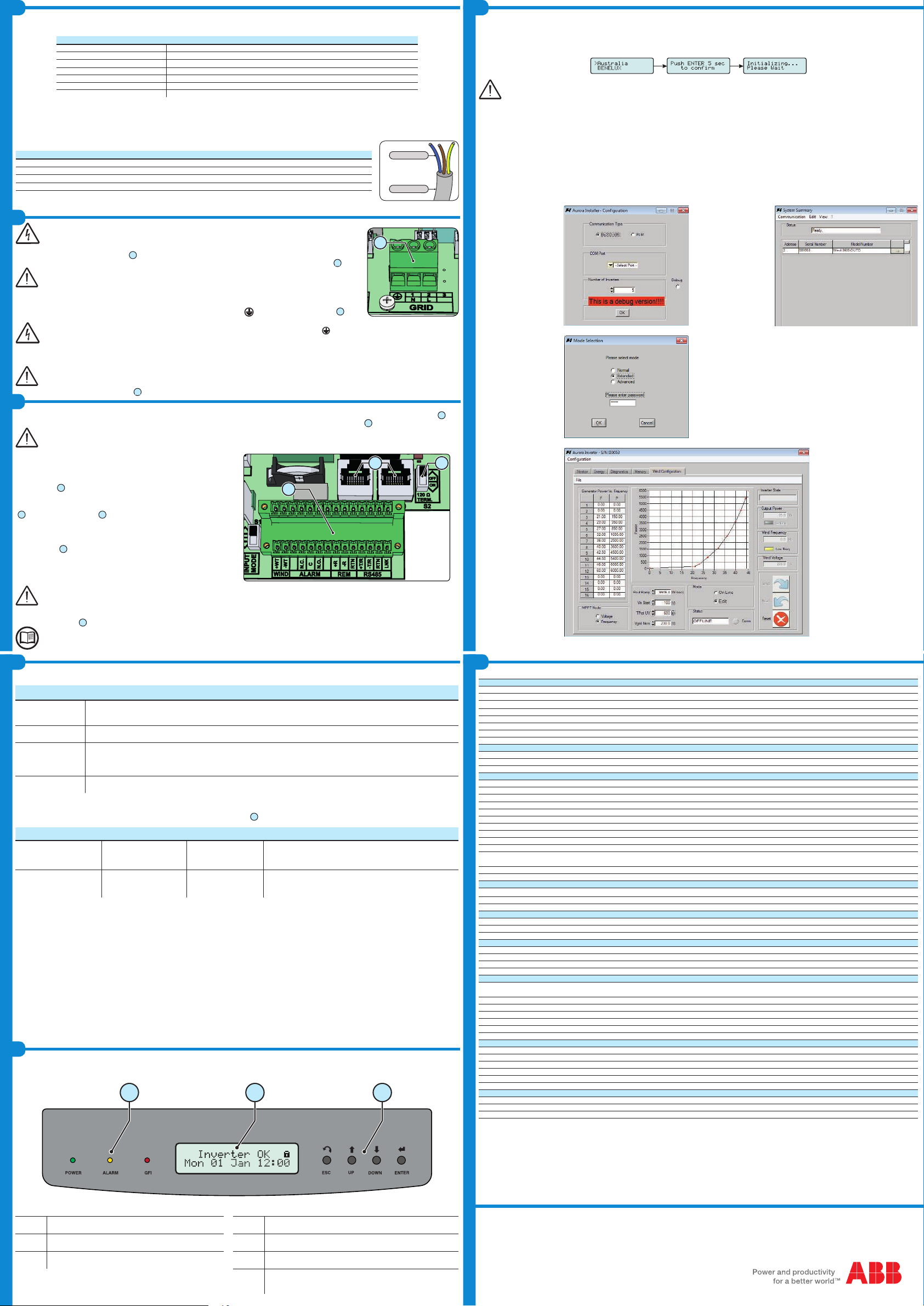

Follow the following step-by-step procedure for upload the power curve:

-

- Install the Aurora Installer application on your PC

-

voltage, provided it can produce at least 50V

- Connect the inverter to your PC using the PVI-USB-RS485_232 converter (for details of the connection, see the PVI-USB-RS485_232 converter manual)

- Launch the Aurora Installer application

1. In the

ration” window select

the COM port from the

pull-down menu, enter

the number of inverters

you have connected to

the PC and click OK.

2. The application will

scan the communica-

tion line looking for the

connected inverters. The

discovered inverters will

be displayed in a table.

Click to select the

inverter you want to

work with.

3. In the

lection” window select

and enter

the following password:

05591. Then click OK.

4. Go to the

tab: the

application will read the

power curve table in the

inverter (this will happen

even if no table has yet

been loaded, in which

case no curve will be

shown in the graph);

5. From mode

go to mode to

compile the power curve

-

ble for information about

compiling the power

curve) Alternatively, to

created previously, click

and select the

6. From mode go to

mode again and click

to send the table to the

inverter.

same curve to more than one

As” to export the curve to your

PC in .mpp format so that it is

available for other inverters.

The following parameters must be provided, with the power curve, by turbine’s manufacturer. See table below for more details about the parameters:

Output Power Ramp

(Pout Ramp)

The value must be between 275 W/sec and 10,000 W/sec. In the commissioning phase of the system, if an instability is detected, try

Inverter Activation

Voltage (Vin Start) This is the input voltage above which the inverter connects to the grid. The value must be between 50V and 200V.

Undervoltage

protection time

(Tprot UV)

-

gy again to the grid whenever the wind pickups, without having to repeat the inverter start-up process. The value must be between 1

sec and 3600 sec.

Nominal Grid Voltage

(Vgrid Nom) Indicates the rated voltage of the grid to which the inverter is connected.

-

show various messages on the display and change the behaviour of the three LED

06

:

INPUT VOLTAGE LED STATUS

Vin < Vstart Waiting Wind

Green = FLASHING

Yellow = OFF

Red = OFF

Vin > Vstart Missing Grid

Green = FLASHING

Yellow = ON

Red = OFF

the inverter waits until there is grid voltage to carry out the parallel

connection.

inverter to start up.

-

grid voltage check, measures the wind power system insulation resistance against earth and carries out other self-diagnosis checks. During the checks before

During the grid voltage check and measurement of the insulation resistance, the values for the grid voltage and frequency and the insulation resi

meet the ranges provided for by the regulations in force and if the insulation resistance is greater than 1Mohm.

- If the preliminary checks for parallel connection to the grid are successful, the inverter connects to the grid and begins to export power to the grid. At this stage,

the display shows the inverter’s parameters in cycles. The green LED stays lit whereas the others are off.

LEDs and BUTTONS, in various combinations, can be used to view the status or carry out complex actions that are described more fully in the manual.

080706

LED

On if the inverter is working correctly. Flashes when

ESC It is used to access the main menu, to go back to the previous menu

or to go back to the previous digit to be edited

LED

The inverter has detected an anomaly. The anomaly

is shown on the display.

UP It is used to scroll up the menu options or to shift the numerical scale

in ascending order

LED

GFI

Ground fault on the DC side of the PV generator. The

error is shown on the display.

It is used to scroll down the menu options or to shift the numerical

scale in descending order

selected option (indicated by the > symbol) or to switch to the next

digit to be edited

Input

Absolute Maximum Input Voltage (Vmax,abs) 600 V

Input Activation Voltage (Vstart) 50 V (adj. 50...350 V)

Input Operating Range (Vdcmin...Vdcmax)50...580 V

Input DC Voltage Range (Vmin,f ... Vmax,f) at Pacr 160...530 V 120...530 V 140...530 V

Maximum DC Input Current (Idc max)20.0 A 32.0 A 32.0 A

Maximum Input Short Circuit Current 25 A 40.0 A 40.0 A

Maximum Backfeed current (from AC to DC side) Negligible

DC Connection Type Screw terminal block

Input protection

Reverse Polarity Protection Yes, from limited current source

Input Overvoltage Protection - Varistor 2

Photovoltaic Array Isolation Control According to local standard

Output

AC Grid Connection Type Monophase

Rated AC Power (Pacr) 3000 W 3600 W 4200 W

Maximum AC Output Power (Pac max)3300 W (1) 4000 W (2) 4600 W (3)

Rated AC Grid Voltage (Vacr) 230 V

AC Voltage Range 180...264 Vac (4)

Maximum AC Output Current (Iac max)14.5 A 17.2 A (5) 20.0 A

Inrush Current Negligible

Maximum Output Fault Current <25 A rms (100mS)

r)

min...fmax)(6)

Nominal Power Factor (Cosphiacr) >0.995 adj. ± 0.9 with Pacr=

3.0 kW

>0.995 adj. ± 0.9 with Pacr=

3.6 kW

>0.995 adj. ± 0.9 with Pacr=

4.2 kW

Total Harmonic Distortion of Current < 3.5%

AC Connection Type Screw terminal block

Output protection

Anti-Islanding Protection According to local standard

Maximum AC Overcurrent Protection 16.0 A 19.0 A 22.0 A

Output Overvoltage Protection - Varistor 2 (L - N / L - PE)

Operating performance

max) 96.8%

Power Input Treshold 10.0 W

Stand-by Consumption < 8.0 W

Communication

Wired Local Monitoring PVI-USB-RS232_485 (opt.)

Remote Monitoring WIFI LOGGER CARD (opt.), PVI-AEC-EVO (opt.), VSN700 Data Logger (opt.)

Wireless Local Monitoring WIFI LOGGER CARD (opt.)

User Interface LCD Display with 16 characters x 2 line

Environmental

Ambient Temperature Range -25...+60°C /-13...140°F with

derating above 50°C/122°F

-25...+60°C /-13...140°F with

derating above 55°C/131°F

-25...+60°C /-13...140°F with

derating above 50°C/122°F

Storage Temperature -40...80°C (-40...+176°F)

Relative Humidity 0...100% condensing

3

Noise Emission < 50 dB(A) @ 1 m

Maximum Operating Altitude without Derating 2000 m / 6560 ft

Environmental Category External

Physical

Environmental Protection Rating IP 65

Cooling Natural

Dimension (H x W x D) 618 x 325 x 222 mm / 24.3 x 12.8 x 8.7 inch

Weight 17.5 kg / 38.6 lb

Mounting System Wall bracket

Overvoltage Category in accordance with IEC 62109-1 II (DC input) III (AC output)

Safety

Isolation Level Transformerless (TL)

Safety Class I

Marking

1. Limited to 3000 W for Germany

2. Limited to 3600 W for Germany

3. Limited to 4200 W for Germany

5. Restricted to 16 A (up to the maximum output power of 3680 W) for the standard UK G83/1.