Insertion-Type Electromagnetic Probe Flowmeter

AquaProbe 2 Contents

IM/AP Issue 9 1

Contents

1 Introduction ...................................................................................................................................... 3

1.1 System Schematic ................................................................................................................... 3

2 Mechanical Installation .................................................................................................................... 4

2.1 Location – Environmental Conditions ....................................................................................... 4

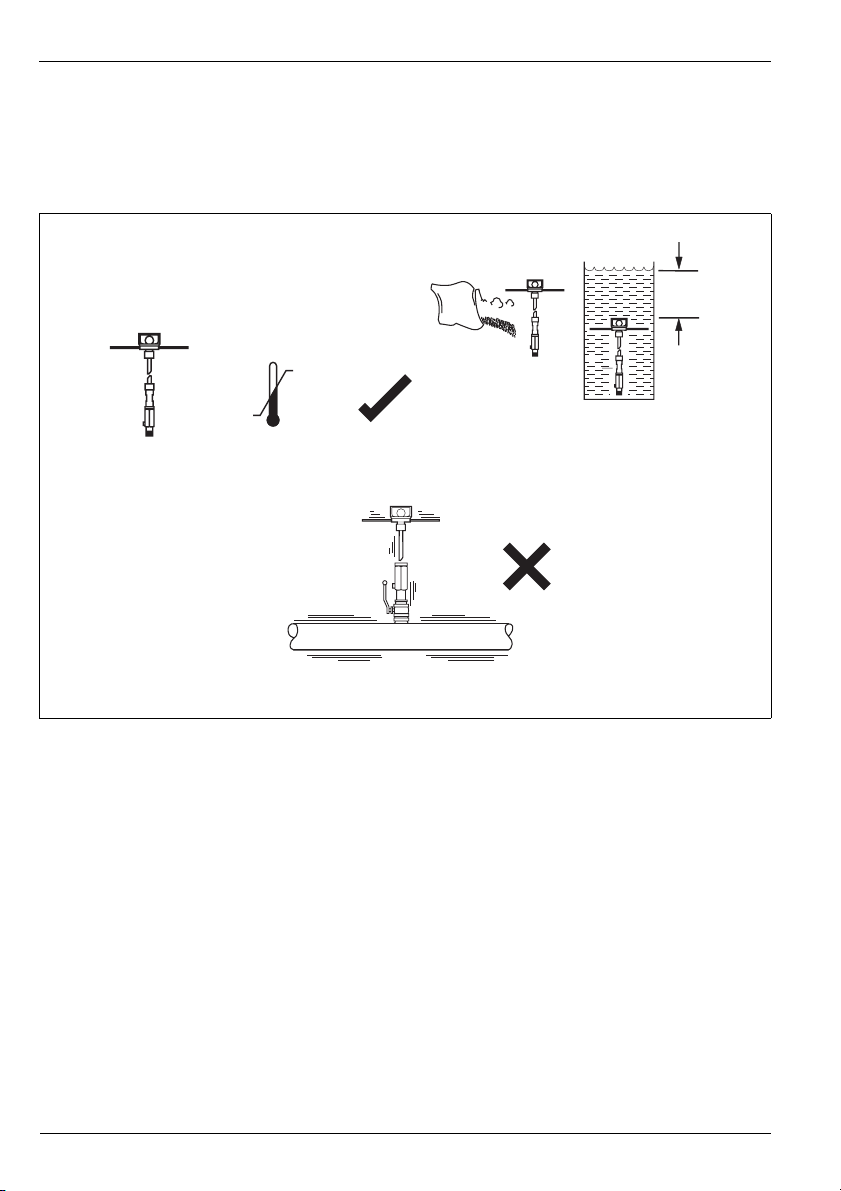

2.1.1 AquaProbe .................................................................................................................... 4

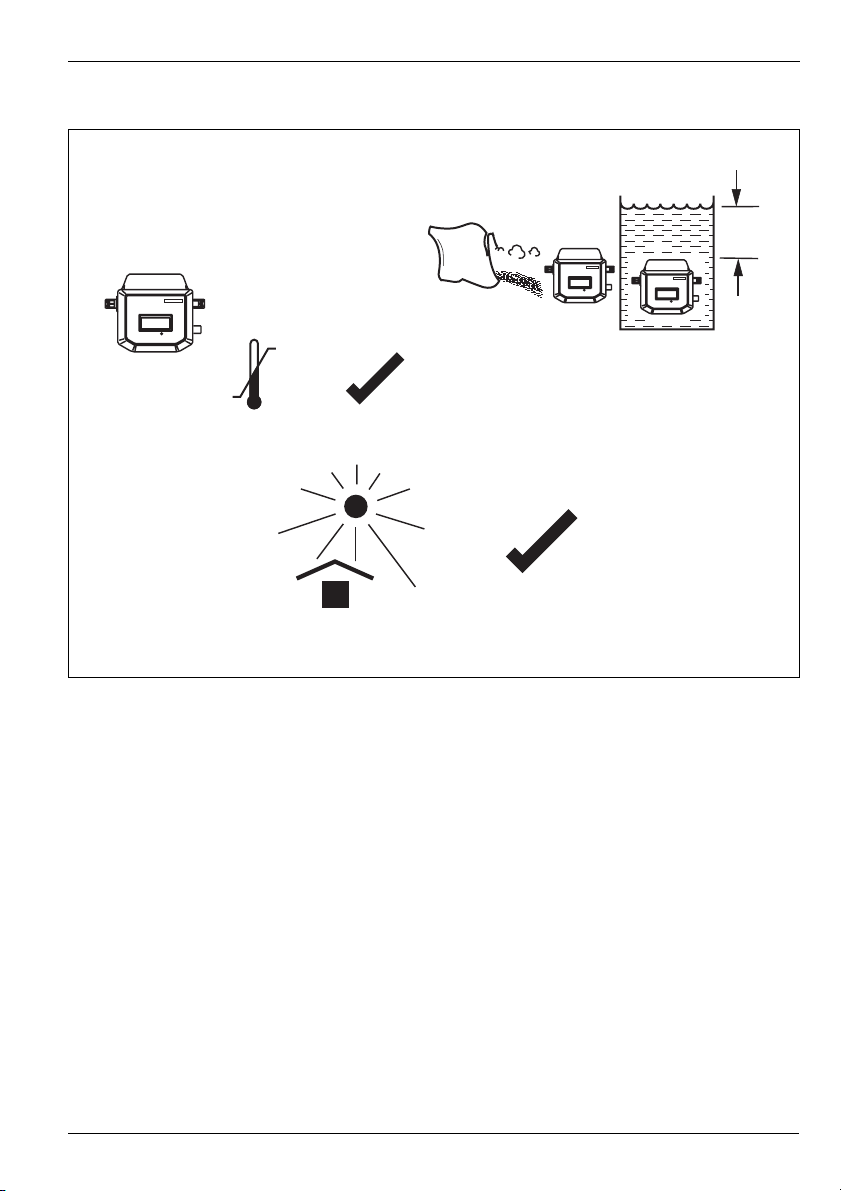

2.1.2 Transmitter .................................................................................................................... 5

2.2 Location – Flow Conditions ...................................................................................................... 6

2.2.1 International Standard for Flow Measurement ................................................................ 6

2.2.2 Velocity Limitations ........................................................................................................ 7

2.3 Location – Mechanical ............................................................................................................. 9

2.3.1 AquaProbe .................................................................................................................... 9

2.3.2 Transmitter .................................................................................................................. 10

2.4 Safety .................................................................................................................................... 11

2.5 Installing the AquaProbe ........................................................................................................ 12

2.6 Setting the Insertion Depth .................................................................................................... 13

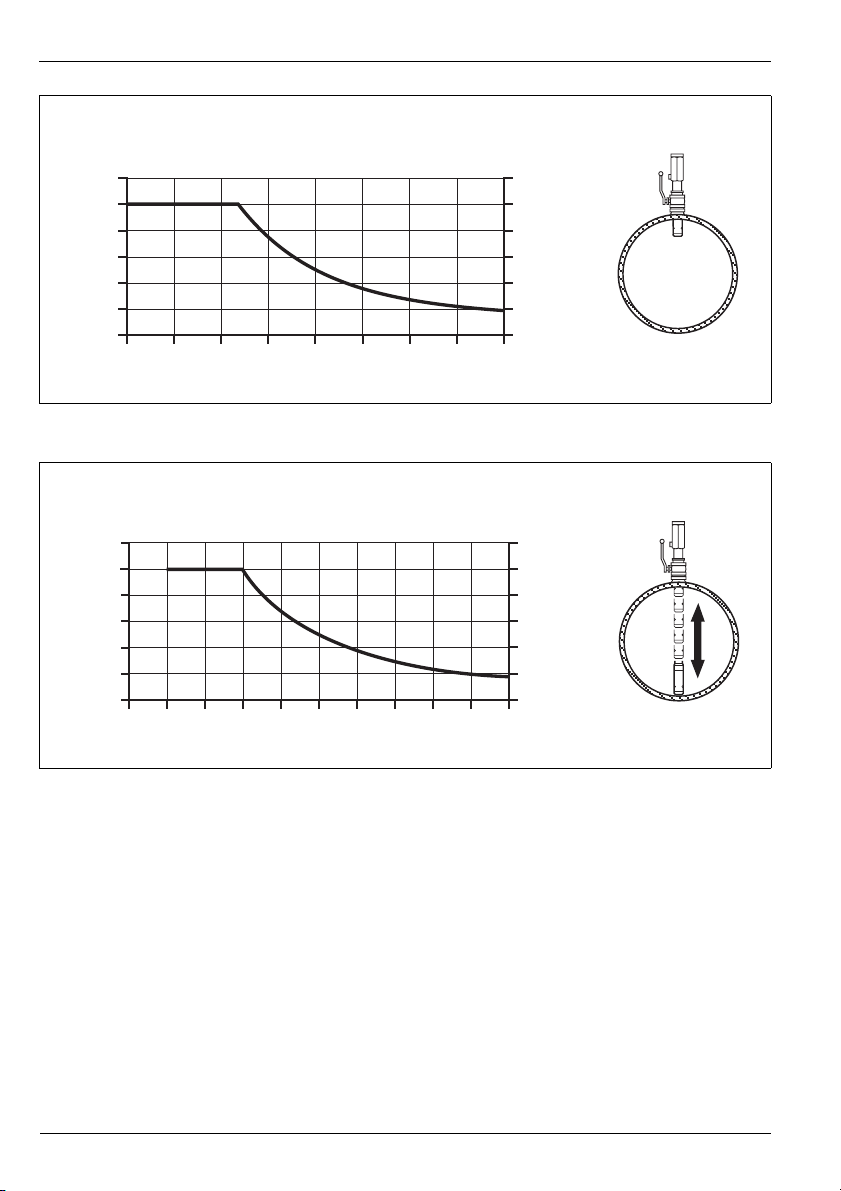

2.6.1 Centre Line Method for Pipe Diameters ≤1m (≤40in ) ................................................... 13

2.6.2 Centre Line Method for Pipe Diameters >1m ≤2m (>40in ≤80in) .................................. 14

2.6.3 Mean Axial Velocity Method ......................................................................................... 15

2.7 AquaProbe Alignment ............................................................................................................ 16

3 Electrical Installation ..................................................................................................................... 17

3.1 Connections .......................................................................................................................... 17

3.1.1 Sensor Terminal Box Connections (Remote Versions only) .......................................... 17

3.1.2 Environmental Protection ............................................................................................. 18

3.1.3 Transmitter Connections ............................................................................................. 19

3.2 Input/Output Connections ..................................................................................................... 21

3.2.1 Frequency Outputs ...................................................................................................... 21

3.2.2 PLC Interface .............................................................................................................. 22

3.2.3 MIL Connector Input/Output Connections (Option) ...................................................... 23

3.2.4 Local Computer Connection ........................................................................................ 24

3.2.5 Remote Computer Connection (Option) ....................................................................... 25

3.2.6 Power Supply Connection Options .............................................................................. 26

3.2.7 Pressure Transducer (Optional) .................................................................................... 28

3.2.8 Environmental Protection (Option) ................................................................................ 29

4 Setting Up ...................................................................................................................................... 30

4.1 Introduction ........................................................................................................................... 30

4.2 Centre Line Method ............................................................................................................... 30

4.3 Mean Axial Velocity Method (1/8 Diameter) ............................................................................ 31

4.4 Partial Velocity Traverse ......................................................................................................... 31

4.5 AquaProbe Transmitter Setup ................................................................................................ 31