Table of contents

7Overview of this specification ..........................................................................................................

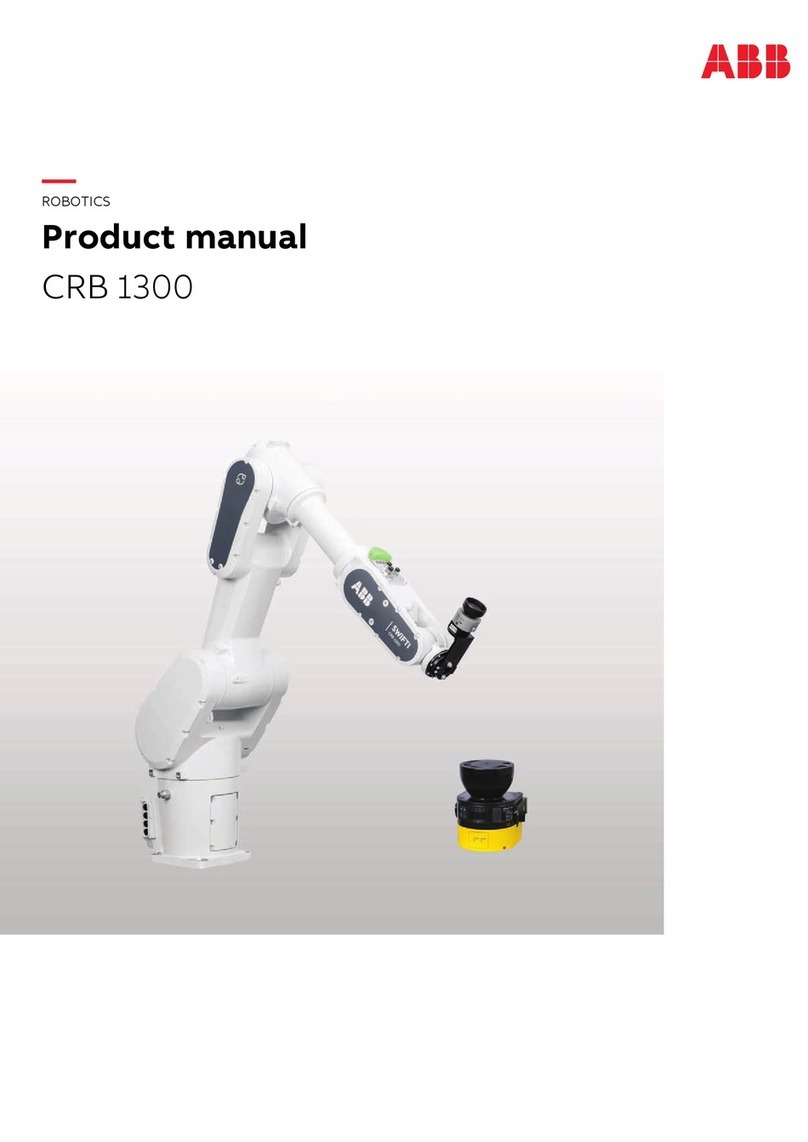

91 Description

91.1 Structure .........................................................................................................

91.1.1 Introduction ............................................................................................

111.1.2 Different robot versions ............................................................................

121.1.3 Definition of version designations ...............................................................

121.1.3.1 Technical data ............................................................................

161.1.3.2 Dimensions ................................................................................

191.1.3.3 Working range ............................................................................

241.2 Standards ........................................................................................................

241.2.1 Applicable standards ...............................................................................

251.3 Installation .......................................................................................................

251.3.1 Introduction to installation .........................................................................

261.3.2 Operating requirements ............................................................................

271.3.3 Mounting the manipulator .........................................................................

281.3.4 Installation of lead-through device ..............................................................

301.3.5 Installation of laser scanner ......................................................................

371.4 Calibration and references ..................................................................................

371.4.1 Calibration methods .................................................................................

391.4.2 Fine calibration .......................................................................................

401.4.3 Absolute Accuracy calibration ...................................................................

441.4.4 Synchronization marks and axis movement directions ...................................

441.4.4.1 Synchronization marks and synchronization position for axes ..............

451.5 Load diagrams ..................................................................................................

451.5.1 Introduction ............................................................................................

461.5.2 Diagrams ...............................................................................................

52

1.5.3 Maximum load and moment of inertia for full and limited axis 5 (center line down)

movement ..............................................................................................

541.5.4 Wrist torque ...........................................................................................

551.5.5 Maximum TCP acceleration .......................................................................

561.6 Fitting equipment on the robot (robot dimensions) ...................................................

601.7 Maintenance and troubleshooting .........................................................................

611.8 Robot motion ....................................................................................................

611.8.1 Adjusting the working range ......................................................................

621.8.2 Mechanically restricting the working range ...................................................

651.8.3 Performance according to ISO 9283 ............................................................

661.8.4 Velocity .................................................................................................

671.9 Robot stopping distances and times .....................................................................

671.9.1 Robot stopping distances according to ISO 10218-1 ......................................

711.9.2 Measuring stopping distance and time ........................................................

731.9.3 CRB 1300 0.9 m 11 kg ..............................................................................

821.9.4 CRB 1300 1.15 m 10 kg ............................................................................

911.9.5 CRB 1300 1.4 m 7 kg ...............................................................................

1001.10 Customer connections .......................................................................................

1052 Specification of variants and options

1052.1 Introduction to variants and options ......................................................................

1062.2 Manipulator ......................................................................................................

1102.3 Floor cables .....................................................................................................

1133 Accessories

115Index

Product specification - CRB 1300 5

3HAC083113-001 Revision: C

© Copyright 2022-2023 ABB. All rights reserved.

Table of contents