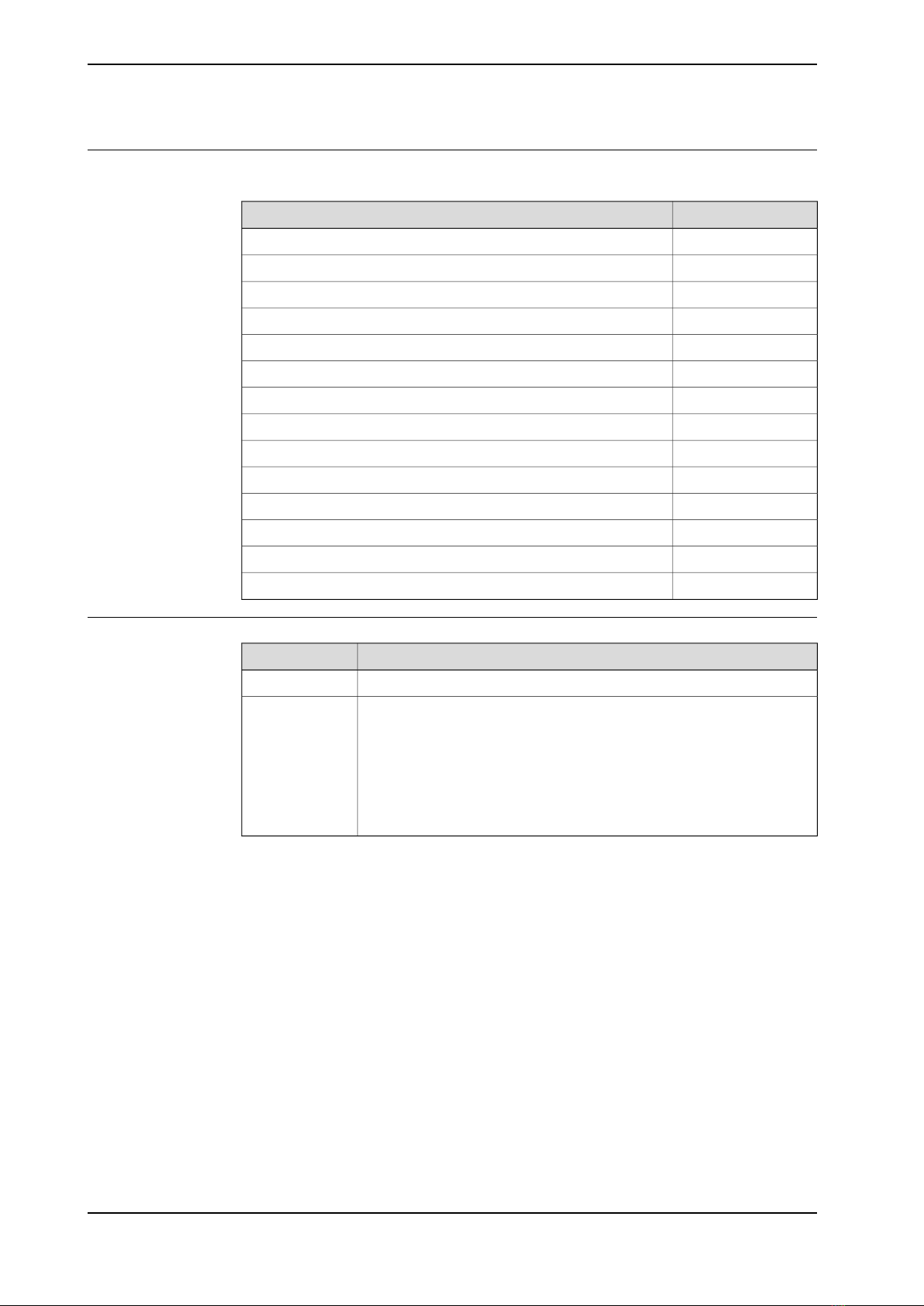

References

Documentation referred to in the manual, is listed in the table below.

Document IDDocument name

3HKA00000191844Product specification - IRT 710

3HAC021313-001Product manual - IRC5

3HAC16590-1Operating manual - IRC5 with FlexPendant

3HAC025709-001Service Information System - IRC5

3HAC021395-001Application manual - Additional axes and stand alone controller

3HAC050948-001Technical reference manual - System parameters

3HAC056372-001IRB 7600 product manual

3HAC055424-001IRB 6650 product manual

3HAC044270-001IRB 6700 product manual

3HAC039838-001IRB 760 product manual

3HAC025755-001IRB 660 product manual

3HAC033453-001IRB 4600 product manual

3HAC022032-001IRB 4400 product manual

3HAC039842-001IRB 460 product manual

Revisions

DescriptionRevision

First edition.A

The following updates are done in this revision:

• Minor corrections.

• Updated content with new drive unit bracket and backlash tool.

• Updated creating and downloading a system procedures.

• Added harness outlet chapter.

• Updated IRB 6660 with 500 mm riser.

• Updated illustrations throughout the manual accordingly.

B

10 Product manual - IRT 710

3HKA00000186299-001 Revision: B

© Copyright 2023 ABB. All rights reserved.

Overview of this manual

Continued