Table of contents

7Overview of this specification ..........................................................................................................

111 Description

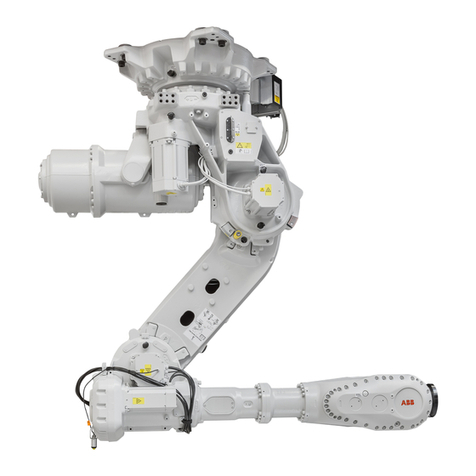

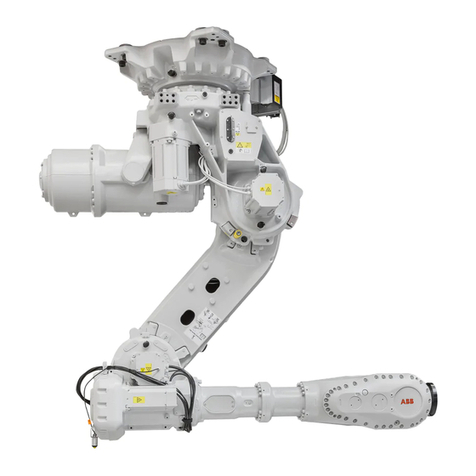

111.1 Structure .........................................................................................................

111.1.1 Introduction to Structure ...........................................................................

141.1.2 Different robot versions ............................................................................

201.2 Standards ........................................................................................................

201.2.1 Applicable standards ...............................................................................

221.3 Installation .......................................................................................................

221.3.1 Introduction to installation .........................................................................

231.3.2 Operating requirements ............................................................................

241.3.3 Mounting the manipulator .........................................................................

281.3.4 Expansion container for inverted mounting of the manipulator .........................

301.4 Calibration and references ..................................................................................

301.4.1 Calibration methods .................................................................................

331.4.2 Fine calibration .......................................................................................

341.4.3 Absolute Accuracy calibration ...................................................................

371.5 Robot load and load diagrams .............................................................................

371.5.1 Introduction to Robot load and load diagrams ...............................................

391.5.2 Load diagrams ........................................................................................

48

1.5.3 Maximum load and moment of inertia for full and limited axis 5 (center line down)

movement ..............................................................................................

501.5.4 Wrist torque ...........................................................................................

511.5.5 Maximum TCP acceleration .......................................................................

521.6 Mounting equipment ..........................................................................................

521.6.1 Information about mounting equipment .......................................................

611.7 Maintenance and Troubleshooting ........................................................................

611.7.1 Introduction to Maintenance and Troubleshooting .........................................

621.8 Robot Motion ....................................................................................................

621.8.1 Introduction to Robot Motion .....................................................................

651.8.2 Performance according to ISO 9283 ............................................................

661.8.3 Velocity .................................................................................................

671.8.4 Robot stopping distances and times ...........................................................

681.9 Cooling fan for axis 1-2 motor ..............................................................................

691.10 Customer connections .......................................................................................

691.10.1 Customer connection on robot ...................................................................

752 Specification of variants and options

752.1 Introduction to variants and options ......................................................................

762.2 Manipulator ......................................................................................................

822.3 Positioners .......................................................................................................

832.4 Floor cables .....................................................................................................

842.5 DressPack .......................................................................................................

852.6 Process equipment ............................................................................................

862.7 User documentation ..........................................................................................

873 Robot description

873.1 Robot types .....................................................................................................

883.2 Non-compatible versions of axis-1 and axis-2 gearboxes ..........................................

934 Accessories

934.1 Introduction to accessories .................................................................................

95Index

Product specification - IRB 2600 5

3HAC035959-001 Revision: AA

© Copyright 2009-2021 ABB. All rights reserved.

Table of contents