- 7 -

Application Software Development

Programming Environment

The application software of the Safety 2600T has been

developed in ANSI C language using the IAR 1.31B compiler.

Emulation and system testing have been performed with the

support of Mitsubishi ICE development system.

Program Structure for Safety Applications

Thecompletesoftwarehasbeenseparatedinasafetyrelevant

andanon-safetyrelevantsections.Thesafetyrelevantareais

constituted by a set of modules and functions which are

rigorously separated and checked in their correct execution.

Safety Logic Programming

A specific document has been developed to define the basic

rulesforC-Programminginsafetyrelatedsystemapplications

in compliance with what defined by the IEC 61508-3. The

software development of the Safety 2600T has been carried

out following the restrictions and recommendation contained

in the above mentioned documents.

Program Compilation

Specialaccuracyhavebeenusedinthesoftwaredevelopment

in order to avoid any error and warnings.

Application Software Testing

A Safety 2600T transmitter functional test report document

has been issued after the operational and the safety related

program have gone through their initial check. It verifies that

the program will perform as desired and specified.

Application Software Safety Validation

The Safety 2600T Application Software testing has been

carried out and audited by TUV PS. A Test Report document

approved by TUV states that the system reacted in each test

as expected and that the safety related program fulfil the

Safety Requirement Specification

Installation

Environmental Requirements

The Safety 2600T pressure transmitter has been designed to

operate in a wide range of environmental conditions typical of

industrial field and in hazardous environments. The

environmentalconditionsunderwhichthemeasuringequipment

is designed to operate within its specified accuracy limits and

withoutimpairmentofitsoperatingcharacteristicsarespecified

in the "Specification Sheet" document.

Mechanical installation and System completion

All the necessary operations to correctly installing the device

in order to assure operator and plant safety are described in

the section "installation" of the present manual.

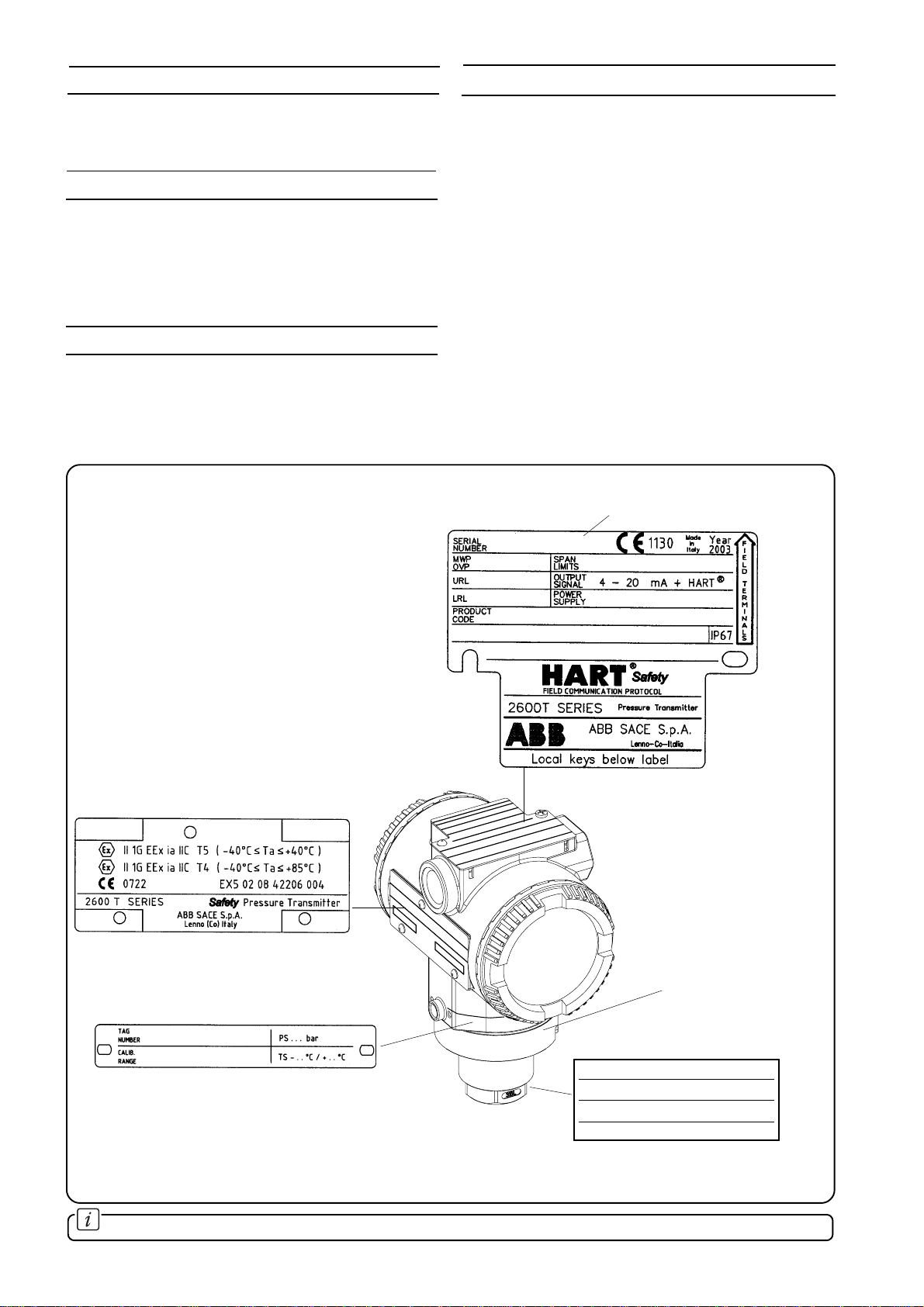

System Wiring

The procedures to safely make the electrical connections of

thedevicearedescribedinthesection"electricalconnections"

of the present manual. For installation in hazardous areas,

compliancewithsafetyinformationonthesafetymarkingplate

shall be ensured.

Commissioning

Field Instrument Functionality

All the necessary activities to assure that the process sensor

orfinalelementareoperatingtogetherandperformtherequired

function are described in the "Electrical connections" and

"Calibration" sections of the present document.

Overall System Functionality

Theactivitiestovalidatetherequired safetyfunctionalityofthe

system together with the target equipment according to the

SafetyRequirementSpecificationarePre-StartupAcceptance

test section of the present document.

Operation

System Operating Discipline

APlantpolicyguidelinedocumentcontainingthespecificplant

policyguidelineforthedailysafeoperationhastobeproduced

and periodically reviewed by representatives of the Process

Control Service.

Maintenance

Maintenance is defined as the routine activities which are

carried out to detect unrevealed faults.

Preventive and Routine Maintenance

Preventive and routine maintenance activities are defined in

the maintenance section of the present manual.

Function-unit Replacement

In case of hardware failure corrective actions may be carried

out. In case of transmitter replacement all the operations

described in "Electrical Connection", "Calibration" and "Pre-

Startup Acceptance tests" shall be conducted.

All maintenance activities shall be documented in the system

documentation.Possiblesafetycriticalfailuresshallbereported

using the Incident Report process.

Function-unit Repair

Thetransmitterisconstitutedoftwomainunits(transducerand

electronics). It can be repaired following the information

contained in the Dismantling and Reassembly section of the

present manual.

Central repair shall maintain a record of detected failures,

calculate actual failure rates and compare with the expected

failure rate. Extensive failure rates shall be communicated to

the supplier.

Modification Request

Request of modification due to possible safety critical failures

and performance deviations shall be reported to the factory.

Modificationsshallfollowthecompanymodificationprocedures.

Management of Change

All process changes or SIL category change shall follow the

procedures defined in the safety life-cycle of the system and

shall be reviewed and validated by the external competent

body for a new functional safety assessment.

Management of change Process Components and Roles

Each process component needs to be defined in details

accordingtotherequirementsandtherelevantdocumentation.

Each process component change shall follow the activities

defined in the overall safety life cycle.

Management of change Documentation and Training

Requirements

TheManagementofChangeprocessshallfollowdocumentation

andtrainingrequirementsdefinedinthesystemimplementation.

. . . . LIFE-CYCLE ACTIVITIES