- 8 -

WARNING - For installation in Hazardous Areas,

i.e. areas with danger of fire and/or explosion, prior to

making electrical connections, ensure compliance with

safetyinformationontheSafetyMarkingplate.Failureto

comply with this warning can result in fire or explosion.

Signal terminals are located in a separate compartment of the

secondary unit housing. The housing incorporates two con-

nection ports for cable glands or conduit fittings. They are

protected with a temporary plastic plug for transit purpose

whichshouldbereplacedwithasuitablepermanentpluginthe

unusedport. Connectionscanbemadebyremovingthecover

(indicatedinFig.7);firstscrewdown thelocking screwlocated

below the cover, using a 3 mm Allen Key.

WARNING - For Hazardous Areas installations,the

connectionofcablesandconduitstothetransmittershall

be made in accordance with the requirements of the

relevant type of protection. Cables and cable-glands

must be in accordance with the type of protection.

Unused openings for connection shall be closed with

blanking elements suitable for the relevant type of

protection. With the exception of intrinsically safe

transmitters, the means provided for this shall be such

that the blanking element can be removed only with the

aid of tools. The blanking elements must be certified for

thetypeofprotection.SeestandardseitherEN60079-14

or IEC 79-14. The transmitter connections must also

guarantee the degree of protection of the transmitter

enclosure,e.g. IPxxaccordingto EN60529standard (or

IEC529).SeealsotheAddendumfor"IP"protection(and

Ex Safety) which is part of this instruction manual.

Thesignalcableshouldbeconnectedtotheterminalsmarked

respectively (+) and (-). If an internal output meter - either with

analog or digital indication - is installed, it should be removed

inordertomaketheconnection,simplybypullingitout fromits

socket. After the connections have been made, reinstall the

output meter. Refer to the Meters Option addendum for

details.

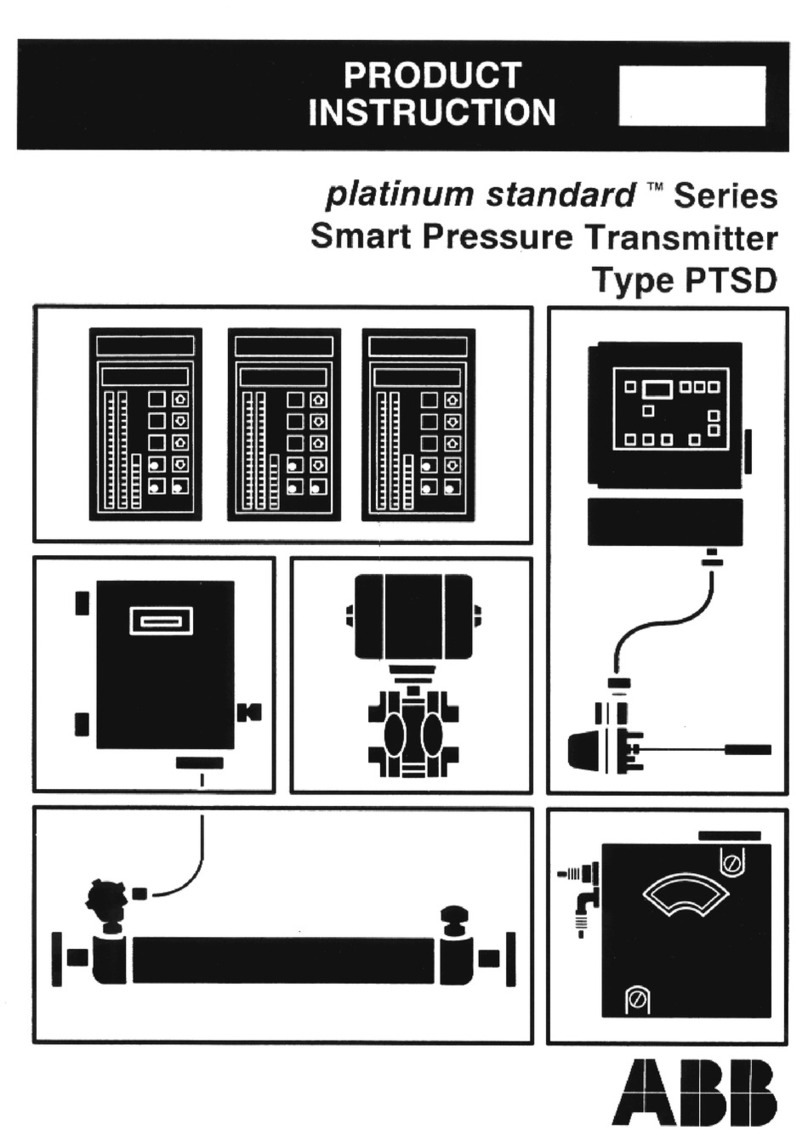

Fig. 7 - Location of the locking screws and terminals

Grub

screw

ELECTRICAL CONNECTIONS

The power to the transmitter is supplied over the signal wiring

and noadditionalwiringis required.Thesignalwiringdoesnot

need to be shielded but the use of a twisted pair is highly

recommended. The cable shield should be grounded in one

side only, to avoid dangerous earth paths.

WARNING - For Hazardous Areas installations,

whentheambient temperatureishigher than70°C,the

cableusedfortheconnectionsmustbesuitablefor5°C

above the ambient temperature.

Normal practice is to ground in the control room side, in which

case the field side of the screen should be adequately

protected to avoid contact with metallic objects. Signal wiring

may be ungrounded (floating) or grounded at any place in the

signalloop,butforintrinsicallysafeinstallationsthewiringand

groundingmustfollowthespecificrulesforthistechnique. The

transmitter case may be grounded or ungrounded: a ground

connectionisprovidedinternally(intheterminal compartment)

and externally.

Do not run the signal wiring in close proximity to power cable

or high power equipment; use dedicated conduits or trays for

signal wiring.

CAUTION - Do not connect the powered signal

wiring to the mA signal testing terminals as this could

damage the by-pass diode.

Aftertheconnectionshavebeencompletedchecktheintegrity

of the cover O-ring, screw down the cover and secure it by

unscrewing the safety screw.

CAUTION - Unless absolutely necessary, avoid

theremoval onsite oftheprotective coverwhich gives

accesstotheelectroniccircuitry.Although theelectro-

nicsare fullytropicalized theyshould notbe subjected

to humidity for long periods.

WARNING - ForHazardous Areas installations,

at least eight (8) threads on each cover must be

engaged in order for the transmitter to meet

(flameproof - explosion-proof) requirements.

Secondary Unit

Cover locking

screws (in the

position

indicated by

the arrows)

Primary

Unit

Remove

this cover

to access

terminals

Hand Held

Communicator

Terminals Test Terminals

Output Meter

Socket

Short circuit link

Ground Terminal

Signal Terminals

Fig. 8a - Terminals arrangements

on Analog + HART version