Ackermann

Page: 9 // 28

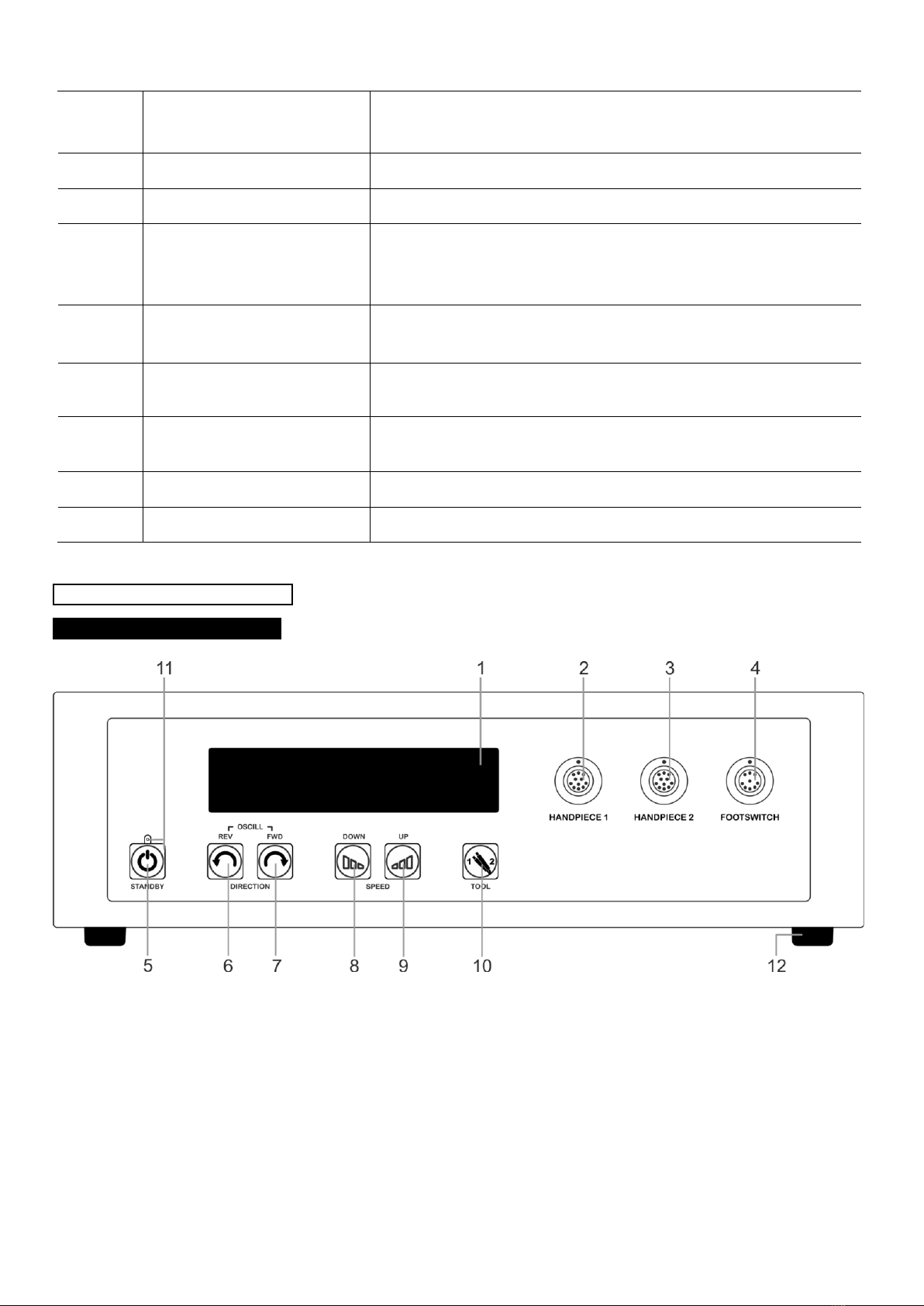

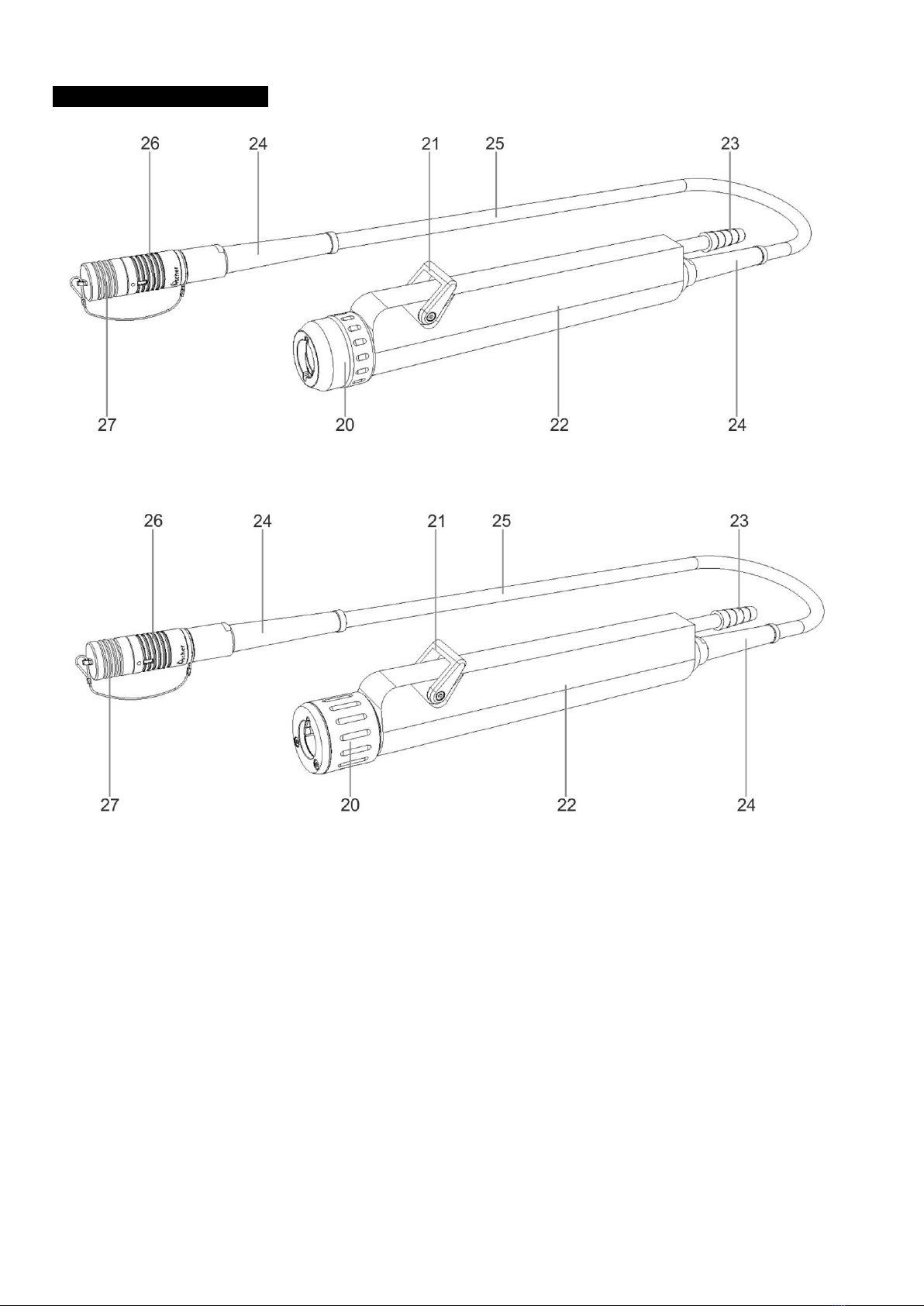

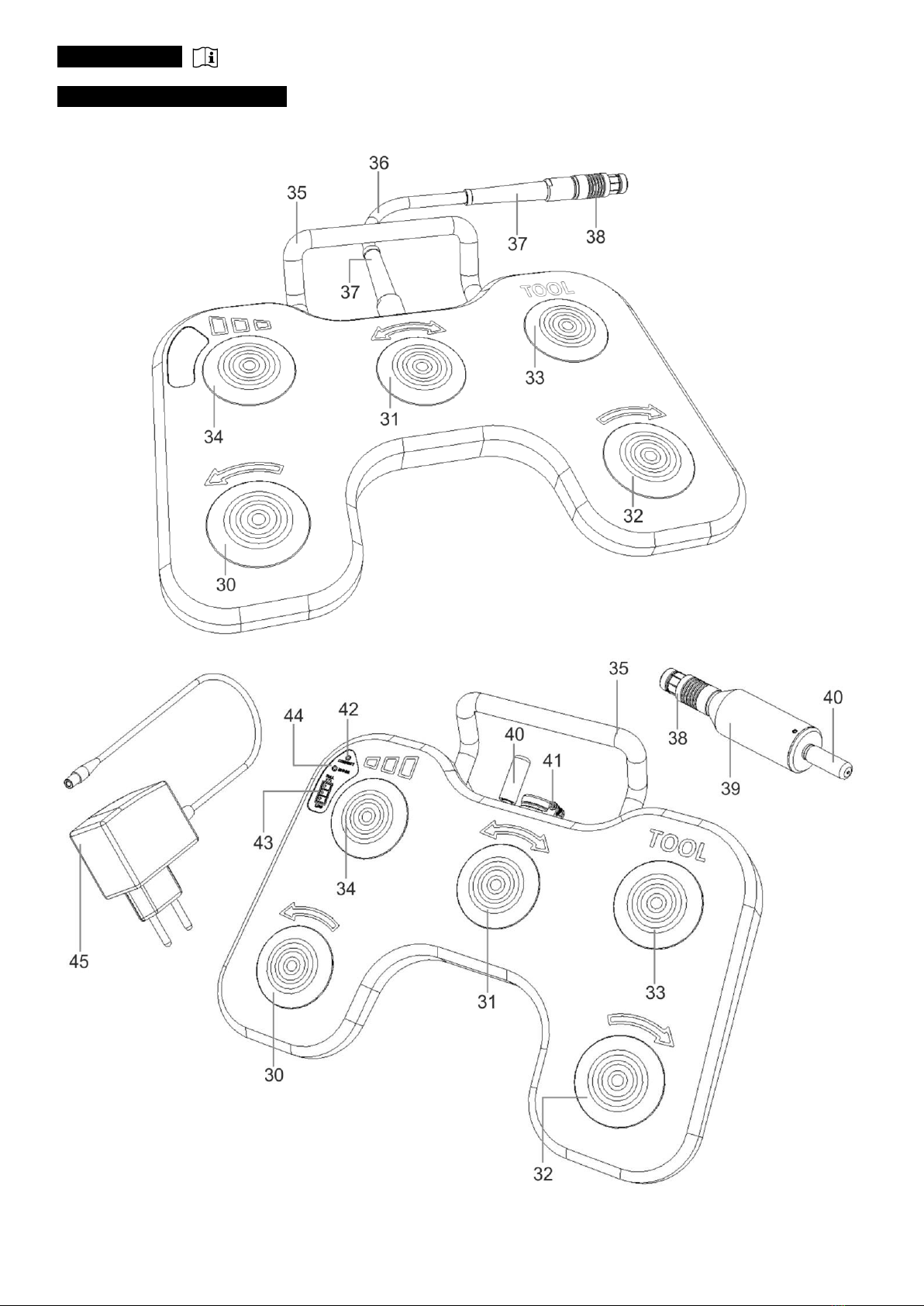

:pedalbuttontoswitchtheshaverbladeintheHandpiecetoanti-clockwiserotation.Thenumberofrotations

dependsonthesetspeedwhichcanbeadjustedviatheUnitControlbuttons(8)and(9)orFootswitchbutton(34).

:pedalbuttontoswitchtooscillatingmode.Thenumberofrotationsdependsonthesetspeedwhich

canbeadjustedviatheControlUnitbuttons(8)and(9)orFootswitchbutton(34).Theoscillationfrequencydependson

settings.

32. FWD:pedalbuttontoswitchtheshaverbladeintheHandpiecetoclockwiserotation.Thenumberofrotationsdepends

onthesetspeedwhichcanbeadjustedviatheControlUnitbuttons(8)and(9)orFootswitchbutton(34).

33. TOOL: pedal button to initiate the change function of the steerable device “HANDPIECE 1” (2), “HANDPIECE 2” (3)

connected to the Control Unit.

:pedalbuttontoregulatethespeedoftheshaverbladeintheHandpieceduringuse.Eachtimethebuttonis

pressed,thespeedisincreasedtothenexthigherlevel.

35. Handle: used for lifting and carrying of the Footswitch.

: connection between the Footswitch and the Control Unit, serves to transmit the selected functions of the

individualFootswitchbuttons(30-34).

37. Protective cap: for increased stability of the connection and protection against fracture.

: connection to attach the Footswitch to the Control Unit. An integrated lock at the plug protects the cable of the

Footswitch from being pulled out by accident.

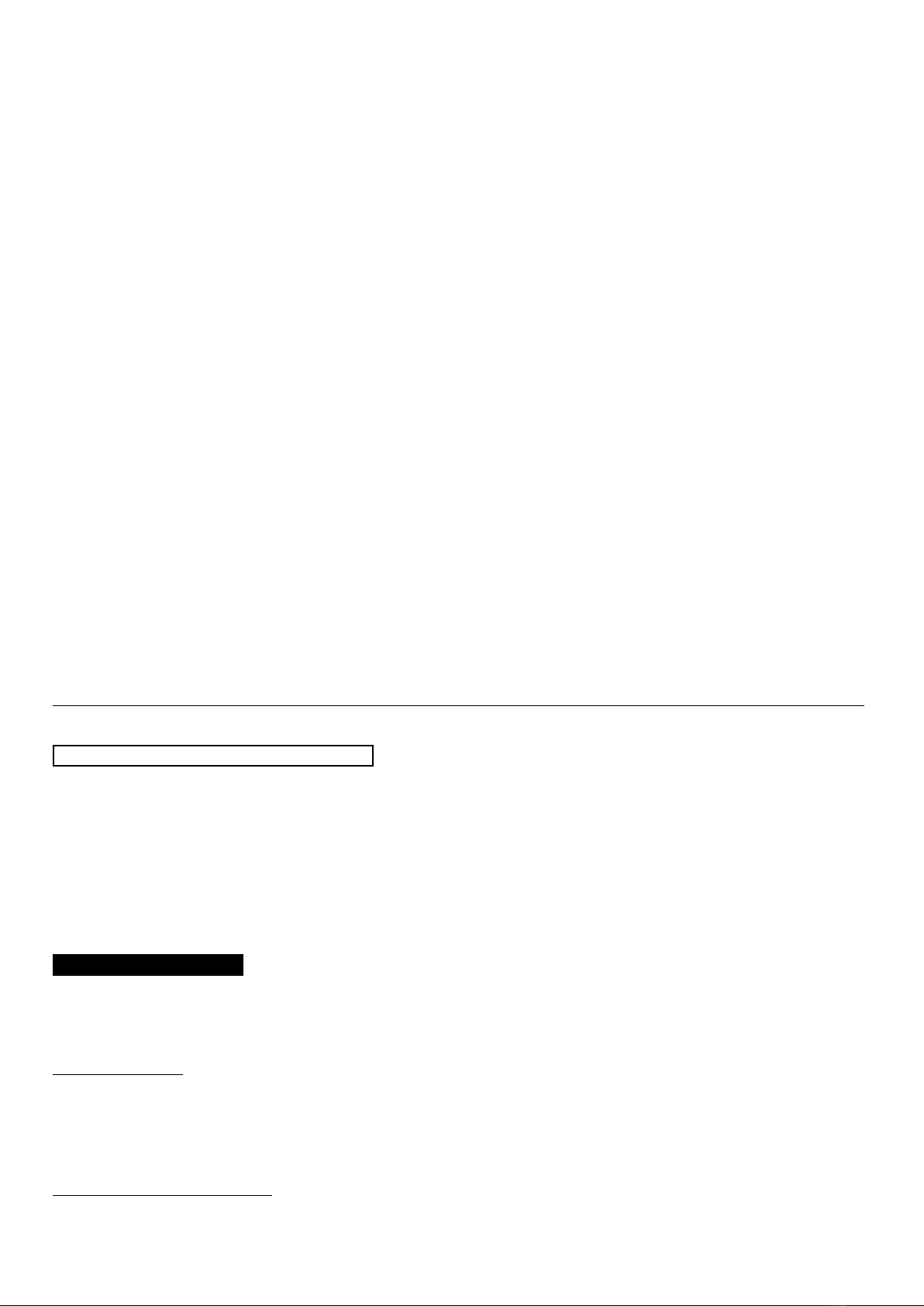

: as a part of the Footswitch serves to transmit information from the Footswitch to the Control Unit, with

which is connected electrically.

: necessary for communication between the Footswitch console and the receiver attached to the Control

Unit.

:usedtoconnectthecharger(45).Chargingshouldbedone outside ofthetreatmentroom. While

charging, functions of the Footswitch are disabled.

:ashingonbluediodesignalsthepropercommunicationbetweentheFootswitchconsoleandthe

receiver(39).

: lighting on green, shows the accumulator level.

: lighting on red diode signals the incorrect charger connection or not compatible charger connection.

: dedicated to charge the accumulator of the Footswitch. Should be used only outside the operating

room.

Thischapterdescribesthecorrectinstallationandstart-upofthedevice.Therststepisthecorrectinstallationofthe

ControlUnit.Thelanguageselectfeatureallowstheoperatortoselectthelanguageofhischoice.Ifthesubsequentsteps

described in chapters 4.1. to 4.6. have been followed correctly, the device is now ready for use and the shaver blades can

be attached.

When the Shaver System Set is not in active use, protect the device against inadvertent actuation of the

Footswitch and the Handpiece!

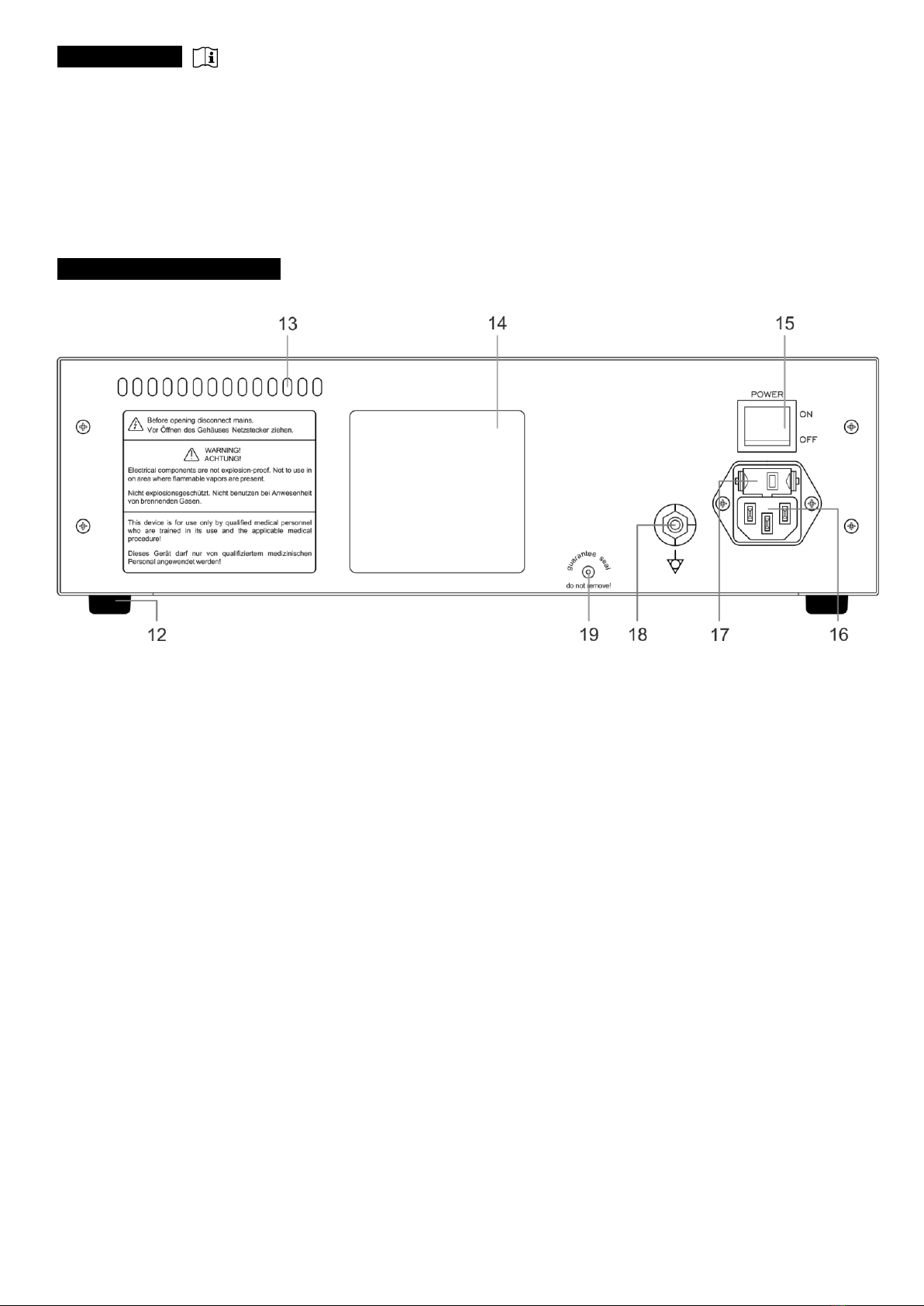

Beforeinstallation,makesurethatthedevicehassucientventilationbymaintainingaminimumdistanceof10cmfrom

the right, left and rear sides of the device.

Device installation:

•theonlyintendedpositionoftheControlUnitishorizontal,inwhichthedeviceisplacedonaatsurfaceonitsfourrubber

feet(12).Inaddition,adequateventilationaroundtheControlUnitmustbeprovided,

•theplaceofinstallationshouldbeaat,dryandcleansurface.Thiscanbeatable,shelfofanendoscopytrolleyorother

elements meant for installation of medical devices.

Connecting the device to power:

•connect,usinganappropriatelead,theequipotentialboltlocatedontherearoftheControlUnittoanequipotentialstrip.

Thecableinsulationshouldbeyellow-green,