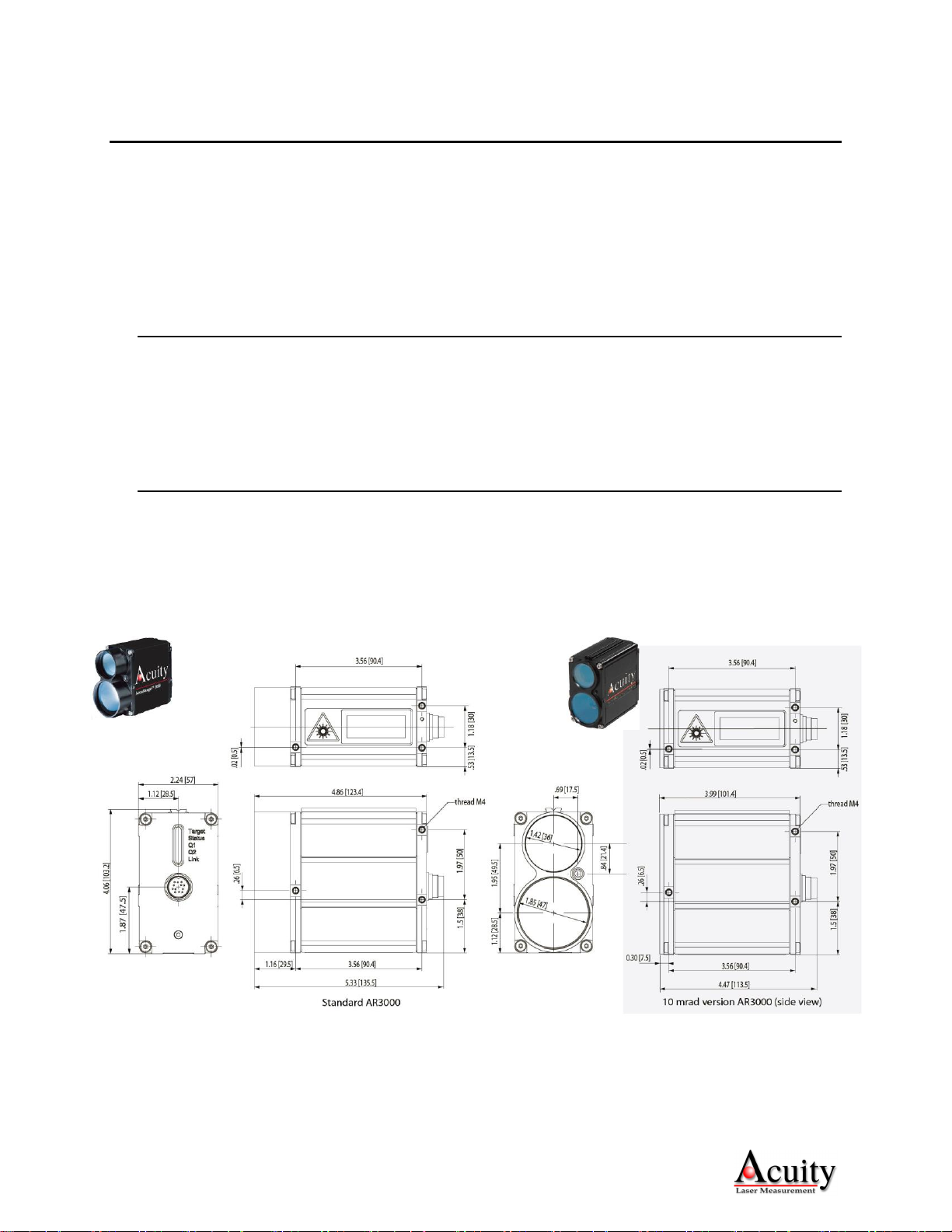

AR3000 User’s Manual

Rev 8/25

Limited Use License Agreement

YOU SHOULD CAREFULLY READ THE FOLLOWING TERMS AND CONDITIONS BEFORE OPENING THE PACKAGE

CONTAINING THE COMPUTER SOFTWARE AND HARDWARE LICENSED HEREUNDER. CONNECTING POWER TO THE

MICROPROCESSOR CONTROL UNIT INDICATES YOUR ACCEPTANCE OF THESE TERMS AND CONDITIONS. IF YOU DO NOT

AGREE WITH THEM, YOU SHOULD PROMPTLY RETURN THE UNIT WITH POWER SEAL INTACT TO THE PERSON FROM

WHOM IT WAS PURCHASED WITHIN FIFTEEN DAYS FROM DATE OF PURCHASE AND YOUR MONEY WILL BE REFUNDED BY

THAT PERSON. IF THE PERSON FROM WHOM YOU PURCHASED THIS PRODUCT FAILS TO REFUND YOUR MONEY, CONTACT

SCHMITT INDUSTRIES INCORPORATED IMMEDIATELY AT THE ADDRESS SET OUT BELOW.

Schmitt Industries Incorporated provides the hardware and computer software program contained in the microprocessor control unit, and licenses

the use of the product to you. You assume responsibility for the selection of the product suited to achieve your intended results, and for the

installation, use and results obtained. Upon initial usage of the product your purchase price shall be considered a nonrefundable license fee unless

prior written waivers are obtained from Schmitt Industries incorporated.

LICENSE

a. You are granted a personal, nontransferable and non-exclusive license to use the hardware and software in this Agreement. Title and

ownership of the hardware and software and documentation remain in Schmitt Industries, Incorporated;

b. the hardware and software may be used by you only on a single installation;

c. you and your employees and agents are required to protect the confidentiality of the hardware and software. You may not distribute,

disclose, or otherwise make the hardware and software or documentation available to any third party;

d. you may not copy or reproduce the hardware and software or documentation for any purpose;

e. your may not assign or transfer the hardware and software or this license to any other person without the express prior written consent of

Schmitt Industries Incorporated;

f. you acknowledge that you are receiving only a LIMITED LICENSE TO USE the hardware and software and related documentation and

that Schmitt Industries Incorporated retains title to the hardware and software and documentation. You acknowledge that Schmitt Industries

Incorporated has a valuable proprietary interest in the hardware and software and documentation.

YOU MAY NOT USE, COPY, MODIFY, OR TRANSFER THE HARDWARE AND SOFTWARE, IN WHOLE OR IN ANY PART,

WITHOUT THE PRIOR WRITTEN CONSENT OF SCHMITT INDUSTRIES, INCORPORATED.

IF YOU TRANSFER POSSESSION OF ANY PORTION OF THE HARDWARE OR SOFTWARE TO ANOTHER PARTY, YOUR LICENSE

IS AUTOMATICALLY TERMINATED. TERM

The license is effective until terminated. You may terminate it at any other time by returning all hardware and software together with all copies

of associated documentation. It will also terminate upon conditions set forth elsewhere in this Agreement or if you fail to comply with any term

or condition of this Agreement. You agree upon such termination to return the hardware and software together with all copies of associated

documentation. In the event of termination the obligation of confidentiality shall survive.

12 MONTH LIMITED WARRANTY

EXCEPT AS STATED BELOW IN THIS SECTION THIS PRODUCT IS PROVIDED “AS IS” WITHOUT WARRANTY OF ANY KIND,

EITHER EXPRESSED OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE.

Schmitt Industries Incorporated does not warrant that the functions contained in the product will meet your requirements or that the operation of

the product will be uninterrupted or error free.

Schmitt Industries Incorporated does warrant as the only warranty provided to you, that the product which is furnished to you, will be free from

defects in materials and workmanship under normal use for a period of twelve (12) months from the date of delivery to you as evidenced by a

copy of your warrant receipt. LIMITATIONS OF REMEDIES

Schmitt Industries Incorporated’s entire liability and your exclusive remedy shall be:

1. the replacement of any hardware and software not meeting Schmitt Industries’ “Limited Warranty” and which is returned to Schmitt

Industries Incorporated or an authorized Schmitt Industries dealer with a copy of your purchase receipt, or

2. if Schmitt Industries Incorporated or the dealer is unable within ninety (90) days to deliver a replacement product which is free of defects in

material or workmanship, you may terminate this Agreement by returning the product and your money will be refunded to you by the dealer from

whom you purchased the product.

IN NO EVENT WILL SCHMITT INDUSTRIES INCORPORATED BE LIABLE TO YOU FOR ANY DAMAGES, INCLUDING ANY LOST

PROFITS, LOST SAVINGS OR OTHER INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OR INABILITY

TO USE SUCH PRODUCTS EVEN IF SCHMITT INDUSTRIES INCORPORATED OR AN AUTHORIZED DEALER HAD BEEN

ADVISED OF THE POSSIBILITY OF SUCH DAMAGES, OR FOR ANY CLAIM BY ANY OTHER PARTY.

SOME AREAS DO NOT ALLOW THE LIMITATIONS OR EXCLUSION OF LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

GENERAL

You may not sublicense, assign or transfer the license or the hardware, software, and documentation except as expressly provided in this

Agreement. Any attempt otherwise to sublicense, assign or transfer any of the rights, duties or obligations hereunder is void.

This Agreement will be governed by the laws of the United States and the State of Oregon, United States of America.

Should you have any questions concerning this Agreement, you may contact Schmitt Industries Incorporated by writing to:

Schmitt Industries Incorporated

2765 NW Nicolai St.

Portland, Oregon 97210 USA

YOU ACKNOWLEDGE THAT YOU HAVE READ THIS AGREEMENT, UNDERSTAND IT AND AGREE TO BE BOUND BY ITS

TERMS AND CONDITIONS. YOU FURTHER AGREE THAT IT IS THE COMPLETE AND EXCLUSIVE STATEMENT OF THE

AGREEMENT BETWEEN YOU AND SCHMITT INDUSTRIES INCORPORATED AND ITS DEALER (“US”) WHICH SUPERSEDED

ANY PROPOSAL OR PRIOR AGREEMENT, ORAL OR WRITTEN, AND ANY OTHER COMMUNICATIONS BETWEEN US RELATING

TO THE SUBJECT MATTER OF THIS AGREEMENT.