© Adam Equipment Company 2007 1

CONTENTS

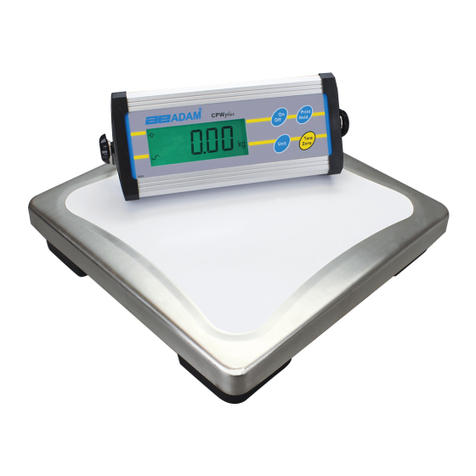

1.0 INTRODUCTION.......................................................................................................2

2.0 SPECIFICATIONS....................................................................................................3

3.0 TROUBLESHOOTING..............................................................................................4

4.0 ERROR CODES .......................................................................................................5

5.0 CBC-M DESCRIPTION.............................................................................................6

6.0 LOAD CELL DAMAGE..............................................................................................6

7.0 CALIBRATION..........................................................................................................9

7.1 CALIBRATION PROCEDURE...............................................................................9

7.2 SECURITY SEALS..............................................................................................10

7.3 CALIBRATION PROCEDURE.............................................................................10

8.0 SERVICE PARAMETERS.......................................................................................11

8.1 USING “0000” TO ENTER THE CALIBRATION PARAMETER............................11

8.2 USING “2006” TO ENTER THE SERVICE PARAMETERS..................................12

8.2.1 F1 -CALIBRATION............................................................................................12

8.2.2 F2 -RESOLUTION ............................................................................................13

8.2.3 F3 –CAPACITY................................................................................................13

8.2.4 F4 -INITIAL ZERO RANGE ...............................................................................14

8.2.5 F5 -RE-ZERO RANGE......................................................................................14

8.2.6 F6 -SUCCESSIVE TARE..................................................................................14

8.2.7 F7 -A/D COUNT.................................................................................................15

8.2.8 F8 –ZERO.........................................................................................................15

8.2.9 F9 –PIN.............................................................................................................15

8.2.10 F10 –LOW VOLTAGE DETECTION..................................................................16

9.0 WIRING DIAGRAM.................................................................................................17

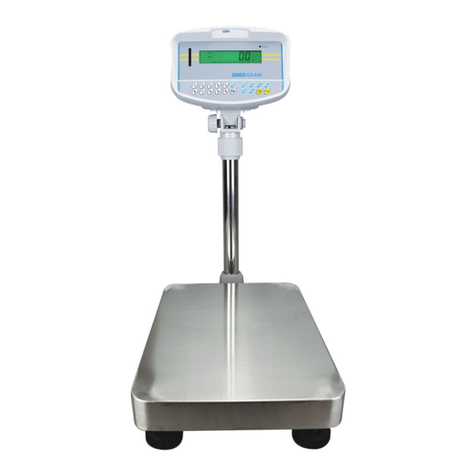

10.0 MECHANICAL ASSEMBLY ....................................................................................18

10.1 LIST OF MECHANICAL ASSEMBLY...................................................................19

11.0 DISPLAY ASSEMBLY.............................................................................................20

*****