Page 6

2. Installation

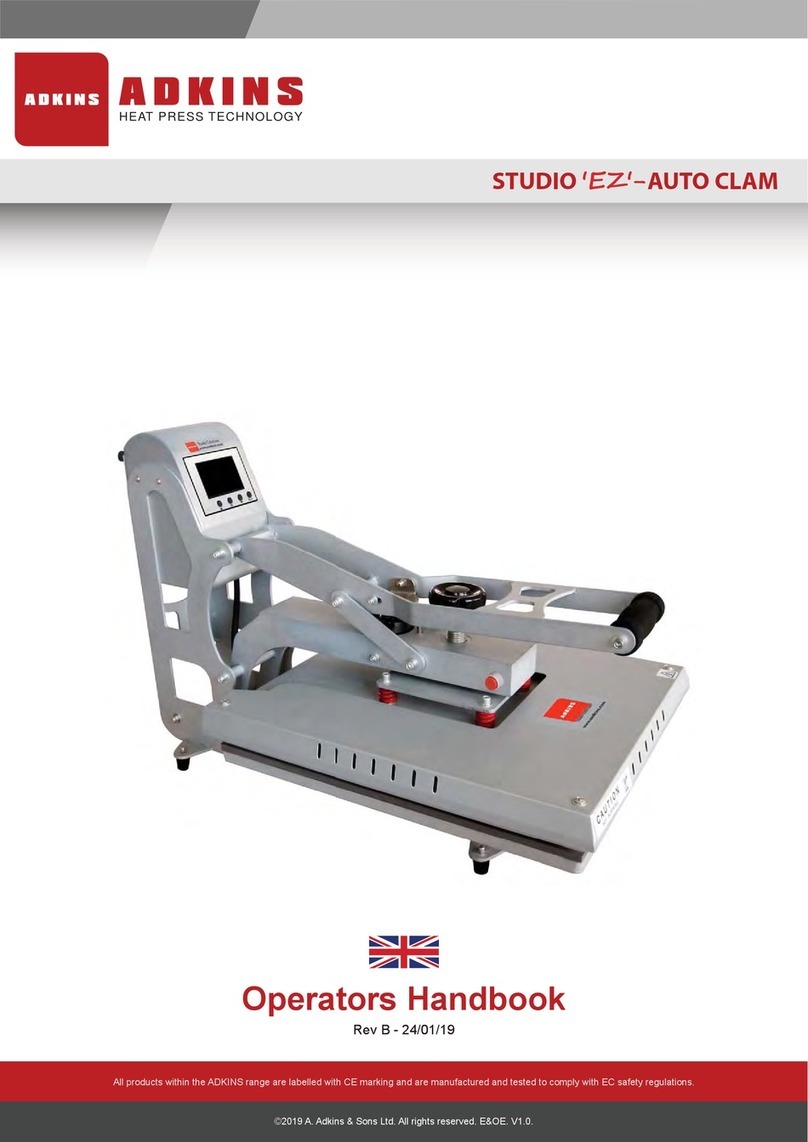

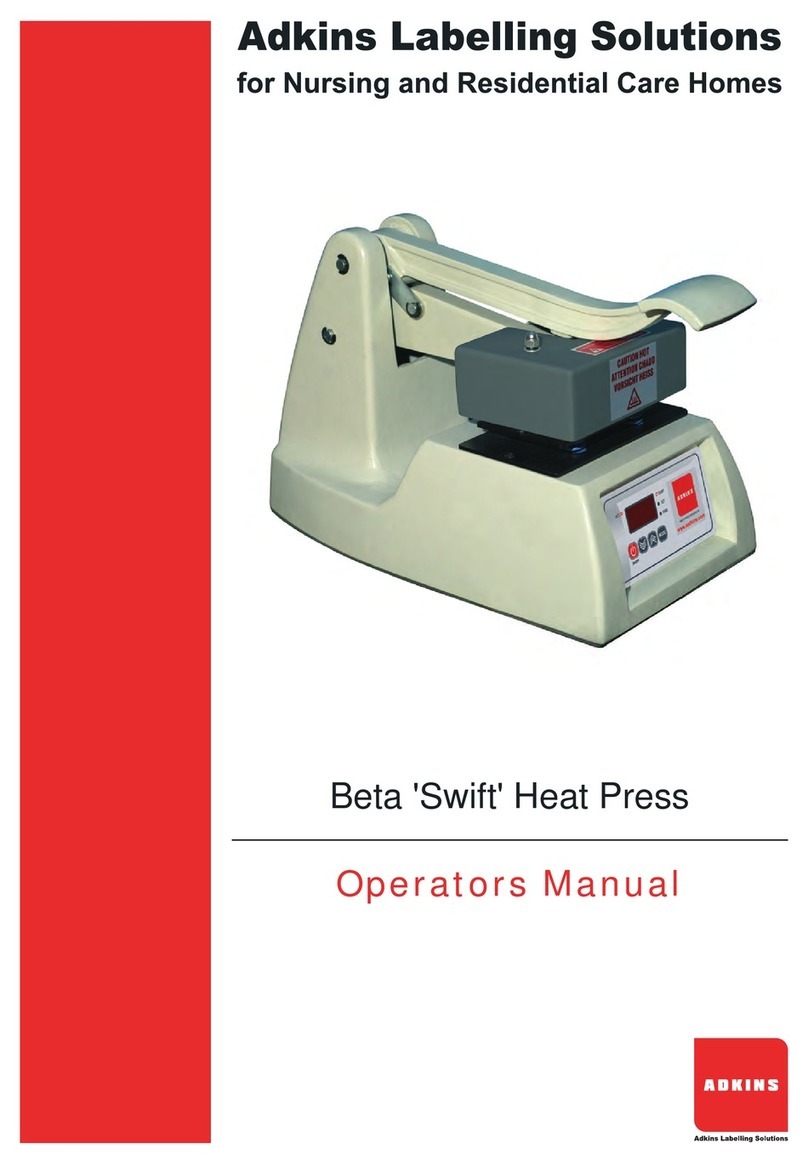

2.1 Transport instructions

The machine comes to you, placed in a cardboard box, and held in

place with foam and banded onto a pallet. If you have to transport the

machine at any time it is recommended that you use a similar box and

packing methods. Please let the machine cool down, lower the handle

to the locked position and remove the swing head handle.

2.2 Installing the machine

2.2.1 Remove all packaging from the heat press.

2.2.2 Check to ensure that no damage has been caused to the

machine during transit.

2.2.3 Place the machine on a sturdy horizontal surface that is within

easy reach of the operator. Due to the weight we recommend

that this be a 2-person task. There must be sufficient space for

the machine’s head to swing to the right until it hits the built-in

stop and for the operating handle to be raised to its full extent.

Ensure that no items vulnerable to heat radiation are too close

to the machine and that local lighting is adequate.

2.2.4 Under some circumstances the machine becomes unstable

when the heat plate is swung to the side for loading. A suitable

bolt is provided with the machine to allow the machine to be

fixed in place using the hole in the front legs casting.

2.3 Wiring the plug for a 115 VAC machine

1. The wire, which has green insulation, must be connected to

the terminal in the plug coloured green or marked GR.

2. The wire, which has white insulation, must be connected to

the terminal in the plug identified as neutral.

3. The wire, which has black insulation, must be connected to

the terminal in the plug which is identified as live (line).

Note: Replacement of the power cord must be carried out by a qualified

electrician in accordance with national and local electrical codes, and

the instructions provided with the plug.