Page 7

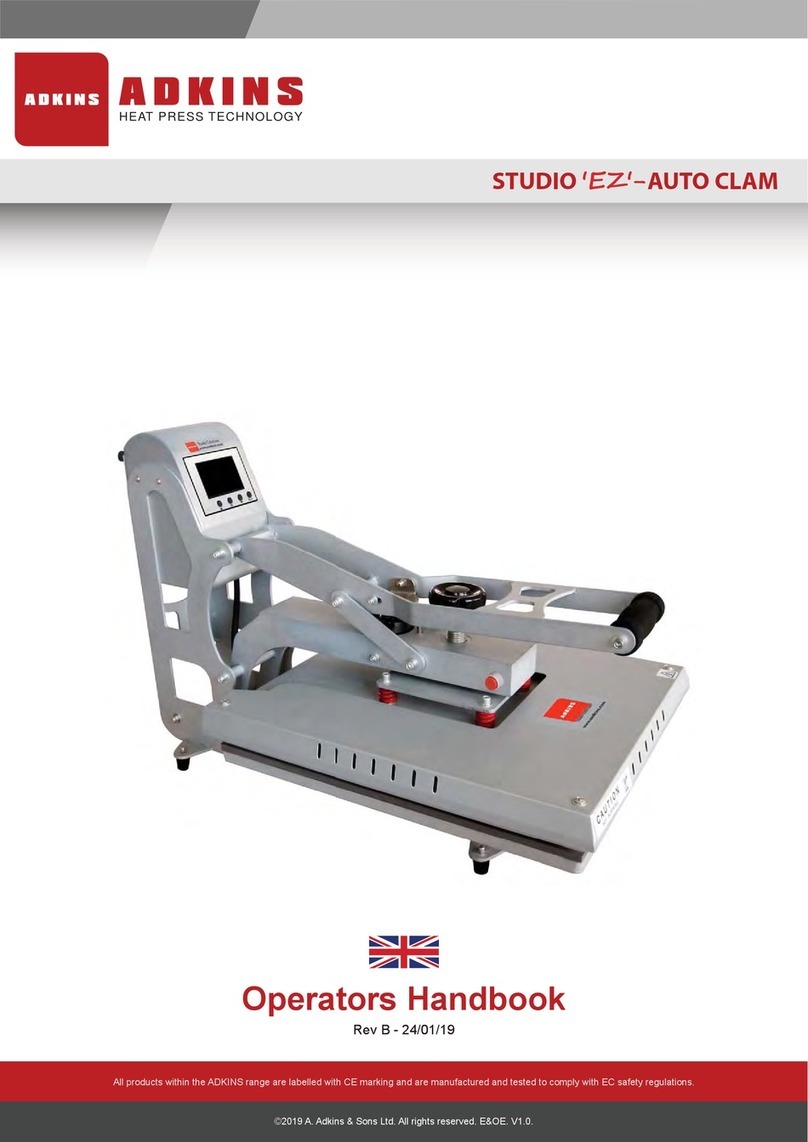

3. How to Operate the Studio

Versa Press

3.1 Starting with the Studio Versa Press

3.1.1 Plug into your supply outlet and switch supply on.

N.B. Please ensure the mains plug is easily accessible to the

operator so that in the event of a fault the machine can be

unplugged.

3.1.2 Turn on the Studio Versa Press; the on/off rocker switch is

on the back of the machine cover and illuminates when “on”.

Set the machine controls as necessary. See instructions for

adjusting the pressure 2.4, and the operation of the time

temperature unit 5.2.

3.2 Working with Heat Transfer Materials

First ascertain from the supplier of the garment/ cap/ plate/ mug that

they are suitable for transfer printing and obtain from them and from the

transfer supplier the correct heat and time dwell setting for the process.

Always check before use that the transfers are either. ‘Hot’ or ‘Cold’

peel. Approximate settings may be as follows:

3.2.1 (Standard) T-shirt, (optional) Cap, (optional) Plate

attachments

a) Adjust the pressure setting of the machine by rotating the

adjusting knob situated on the top of the machine (See

exploded diagram in this manual) clockwise for more

pressure, anticlockwise for less pressure. Place transfer and

substrate into machine, positioning it as required. Make any

final adjustments using the pressure setting.

b) From a cold start-up allow the press to heat up to the desired

temperature.

c) To achieve a good transfer result the transfer paper should be

placed in the desired position on the substrate, removing all

wrinkles. Set the pressure adjustment so that there is good

contact with the substrate.

d) When the temperature indicator on the controller reaches the

set value the machine is ready to print. When you are satisfied

that the transfer is in the correct position gently close the

press with the handle. Immediately press the timer button on

top of the control unit to start the pressing cycle.

N.B. The handle must be in the locked position ensuring that

the work is fully clamped.