6IFCLITY 1006 - 5773010_00

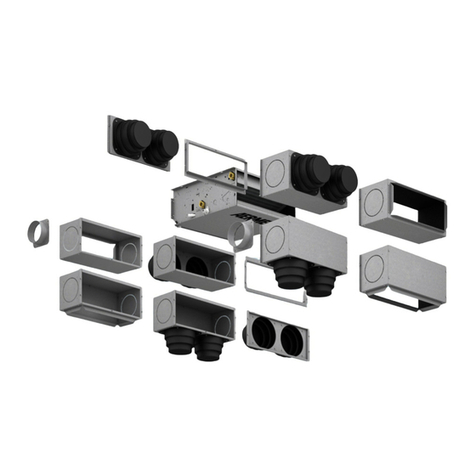

The fan coils are shipped in stand-

ard packaging, which consists of

expanded polystyrene foam and

cardboard shells.

PACKAGING

WARNING: the fan coil is connected

to the power supply and a water

circuit. Any operation by persons

who do not possess the required

technical skills can lead to personal

injury to the operator or damage to

the unit and surrounding objects.

POWER THE FAN COIL ONLY WITH

230V, SINGLE-PHASE VOLTAGE

Any other type of power supply could

permanently damage the fan coil.

DO NOT USE THE FAN COIL

IMPROPERLY

Do not use the fan coil for animal hus-

bandry applications (e.g. incubation).

AIR THE ROOM

Periodically air the room in which

the fan coil has been installed. This

is particularly important if the room

is occupied by many people, or if

gas appliances or sources of odours

are present.

ADJUST TEMPERATURE ADEQUATELY

The room temperature should be

adjusted in order to provide maxi-

mum comfort to the people in the

room, especially if they are elderly,

children or sick people; avoid differ-

ences over 7°C between the outdoor

temperature and the temperature

inside the room in summer.

In summer, a temperature that is too

low causes higher electrical con-

sumption.

CORRECT AIR JET AIMING

ADJUSTMENT

Air coming out from the fan coil must

not reach people directly; in fact,

even if the air is warmer than the

room temperature, it could cause

a cold sensation and result in dis-

comfort.

DO NOT USE EXCESSIVELY HOT

WATER

Clean the fan coil with a soft cloth

or sponge soaked in water not over

40°C. Do not use chemical products

or solvents to clean any part of the

fan coil. Do not spray water on the

outer or inner surfaces of the fan coil

(it might cause short circuits).

CLEAN THE FILTER FREQUENTLY

Cleaning the filter frequently guaran-

tees enhanced operating efficiency.

Check whether the filter is very dirty:

in this case, clean it more often.

Clean frequently; remove the accu-

mulated dust with a vacuum cleaner.

Once the filter is clean, refit it to

the fan coil following the removal

instructions but in reverse order.

SUPPLEMENTARY CLEANING

The fact that the blades of examinable

shrouds can be removed (operation

done only by adequately skilled

technicians) ensures a thorough

cleaning of the internal components,

which is particularly important when

installing the unit in crowded areas

or venues requiring high hygiene

standards.

DURING OPERATION

Always leave the filter fitted on the

fan coil during operation (otherwise

dust in the air could soil the coil

surface area).

WHAT IS NORMAL

In cooling mode, water vapour may

be present in the air delivery of the

fan coil.

In the heating operation, a slight hiss

might be heard close to the fan coil.

Sometimes the fan coil might give

off unpleasant smells due to the

accumulation of substances present

in the air of the room (clean the filter

more often, especially if the room is

not ventilated regularly).

While the unit is functioning, there

could be noises and creaks inside

the device due to the various ther-

mal expansions of the elements

(plastic and metal), but this does

not indicate any malfunction and

does not damage the unit unless the

maximum input water temperature

is exceeded.

MALFUNCTIONS

In case of malfunction, cut off power

to the unit, then energise it again

and restart the device.

WARNING! Do not attempt to repair

the unit by yourself; this is highly

dangerous!

If the problem occurs again, call the

local After-Sales Service immediately.

This section is reserved for the After Sales

Service only. On the Inverter board there

are 2 LEDs (Alarm / Power) indicating

the operating status of the unit. The table

for decoding the messages is given in the

chapter on installation.

DO NOT TUG THE ELECTRIC CABLE

It is very dangerous to pull, tread on

or crush the electric power cable,

or fix it with nails or drawing pins.

A damaged power cable can cause

short circuits and injure people.

DO NOT OBSTRUCT THE AIR OUTLETS

BY PLACING OBJECTS INTO THEM

Do not put anything in the air outlet

slots.

This could injure people and damage

the fan.

WARNING

Do not let children or unskilled peo-

ple use the device without supervi-

sion. Remember also that the device

must not be used by children as a

plaything.

IMPORTANT INFORMATION AND MAINTENANCE