Aesculap ELAN 4 Manual

AESCULAP®

USA Instructions for use/Technical description

ELAN 4 electro control unit GA800

Document No.: IFU - Version: 3.0 - Document ID: SOP-AIC-5001568 Date/Time Printed/Viewed: 2022-04-13 15:59 (CET)

Effective

11

12

13

14

11

15

16 1817

12 34

567

8

9

10

Document No.: IFU - Version: 3.0 - Document ID: SOP-AIC-5001568 Date/Time Printed/Viewed: 2022-04-13 15:59 (CET)

Effective

19 20 21

22232425

27

28

29

30

26

29

28

30

31

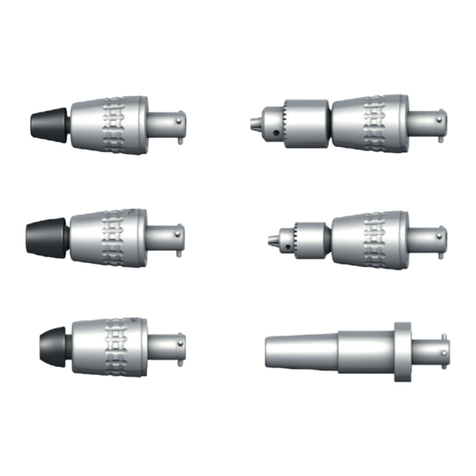

GA810GA808

Document No.: IFU - Version: 3.0 - Document ID: SOP-AIC-5001568 Date/Time Printed/Viewed: 2022-04-13 15:59 (CET)

Effective

GA804

GA805

GA806

GD412804 GA395SU

GA808

GA849

GA822

GA861–GA864

GA865–GA869

GA860

GA836

GA831

GA837

GA832

GA824

GA833

GA844

GA810

Document No.: IFU - Version: 3.0 - Document ID: SOP-AIC-5001568 Date/Time Printed/Viewed: 2022-04-13 15:59 (CET)

Effective

2

USA

AESCULAP®

ELAN 4 electro control unit GA800

Legend

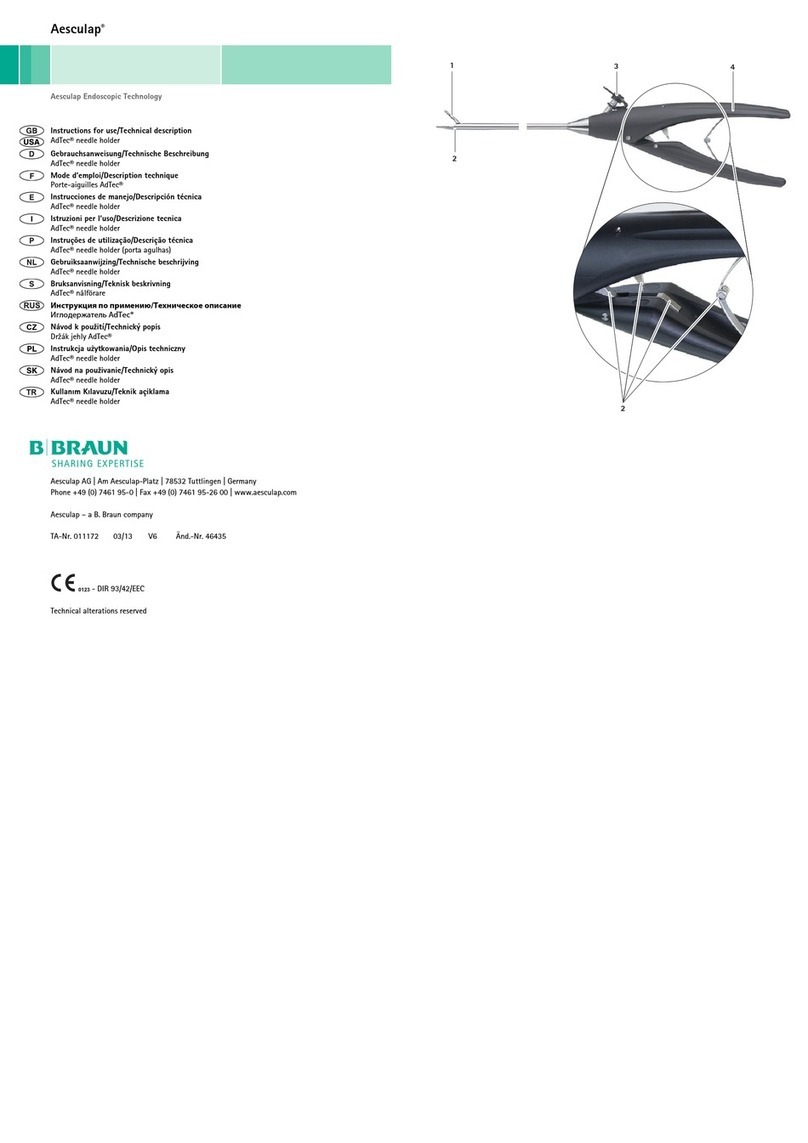

1ELAN 4 electro control unit GA800

2Display with touch control panel

3Coolant and irrigation pump

4Flap

5Indicator light

6Connection socket for foot control

7Connection sockets for motor cable

8Power OFF switch

9Power ON indicator

10 Power ON switch

11 Ventilation grate

12 Fuse holder

13 Power socket

14 Terminal for equipotential bonding conductor

15 Bottle holder mount

16 Bottle holder

17 USB interface: Only intended for use by the manufacturer or by Service

technicians authorized by Aesculap.

18 Interface RS232: Only intended for use by the manufacturer.

Motor cable/applied part

19 Connection for applied part

20 Visual field "Off"

21 Visual field "On"

22 Release button

23 Lug

24 Connection for motor cable on applied part

25 Slider for tool release

26 Pull back unlocking sleeve

27 Connection for control unit

Foot control

28 Function button

29 Pedal

30 Rotational direction button for motor

31 Speed range limit button (only for wireless foot control GA810)

Symbols on product and packaging

Caution

Observe important safety information such as warnings

and precautions in the instructions for use.

Follow the instructions for use

“OFF” (power supply)

“ON” (power supply)

Type BF applied part

Foot control

Terminal for equipotential connector according to

IEC/DIN EN 60601-1

Fuse

Alternating current

Manufacturer

Labeling of electrical and electronic devices according

to directive 2012/19/EU (WEEE), see Chapter 13.

Date of manufacture

Manufacturer’s batch designation

Manufacturer’s serial number

Manufacturer’s article number

Delivery quantity

Temperature limits during transport and storage

Air humidity limits during transport and storage

Atmospheric pressure limits during transport and stor-

age

Non sterile medical device

CE marking according to Directive 93/42/EEC

Federal law restricts this device to sale by or on order of

a physician

Document No.: IFU - Version: 3.0 - Document ID: SOP-AIC-5001568 Date/Time Printed/Viewed: 2022-04-13 15:59 (CET)

Effective

3

USA

Applied part types Display/control elements in the applied part

control panel

Display/control elements in the pump control

panel

Symbol Text Art. no. Designation

Perforator GA822 ELAN 4 electro perforator

driver

Intra GA824 ELAN 4 electro Lowspeed

motor with intra coupling

Saw GA831 ELAN 4 electro sagittal

saw

GA832 ELAN 4 electro reciprocat-

ing saw

GA833 ELAN 4 electro transverse

saw

GA836 ELAN 4 electro micro sag-

ittal saw

GA837 ELAN 4 electro micro

reciprocating saw

Highspeed GA849 ELAN 4 electro cranio-

tome and multifunctional

handpiece (2-ring)

GA860 ELAN 4 electro MIS

hand piece

GA861 ELAN 4 electro Standard

handpiece (1-ring) L4

GA862 ELAN 4 electro Standard

handpiece (1-ring) L7

GA863 ELAN 4 electro Standard

handpiece (1-ring) L10

GA864 ELAN 4 electro Standard

handpiece (1-ring) L13

GA865 ELAN 4 electro Standard

handpiece (2-ring) L7

GA866 ELAN 4 electro Standard

handpiece (2-ring) L10

GA867 ELAN 4 electro Standard

handpiece (2-ring) L13

GA868 ELAN 4 electro Standard

handpiece (2-ring) L17

GA869 ELAN 4 electro Standard

handpiece (2-ring) L22

Drill GA844 ELAN 4 electro power drill

Symbol Designation

Activation mode of motor via foot control GA808

Activation of motor via wireless foot control GA810

Activation of motor via hand control

GA804/GA805/GA844

Motor direction indicator for clockwise rotation pre-

selected

The display depends on whether the motor is acti-

vated or disabled.

Motor direction indicator for counterclockwise rota-

tion preselected

The display depends on whether the motor is acti-

vated or disabled.

Reduce the maximum speed setting

Increase the maximum speed setting

Symbol Designation

Identification of the control panel for the coolant

and irrigation pump

Display in active applied part control panel

Switch on the pump

Switch off the pump

Activate the “Flush” function (continuous flushing)

Reduce the delivery rate

Increase the delivery rate

Document No.: IFU - Version: 3.0 - Document ID: SOP-AIC-5001568 Date/Time Printed/Viewed: 2022-04-13 15:59 (CET)

Effective

4

USA

Display/control elements in the system set-

tings menu

Symbol Designation

Call up the system settings menu

Leave the system settings menu

User profiles

Applied part settings

Control unit settings

Wireless foot control settings

Control unit information

Maximum speed/stroke rate

Speed up

Slow down

Oscillation mode

Oscillation angle

Flow rate

Increase the value

Reduce the value

System volume

Display brightness

System language

Reset device to factory settings

Go back to menu structure

Call up the submenu

Move down list

Move back up list

Add new user profile

Delete existing user profile

Edit existing user profile

Save user profile

Symbol Designation

Document No.: IFU - Version: 3.0 - Document ID: SOP-AIC-5001568 Date/Time Printed/Viewed: 2022-04-13 15:59 (CET)

Effective

5

USA

Contents

1. About this document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Intended use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Application Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Contraindications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3. Safe handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4. Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.1 Scope of supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.2 Components required for operation . . . . . . . . . . . . . . . . . . . . . . 7

4.3 Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3.1 Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3.2 Display/control concept. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3.3 Explanation with an example . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3.4 Applied part types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.3.5 Identification of control elements on system components . . . 8

4.3.6 Recognition of connected motor cable and applied part. . . . . 8

4.3.7 Overload protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.3.8 Coolant and irrigation pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5. Preparation and setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1 Set-up environment/set-up location . . . . . . . . . . . . . . . . . . . . . 8

5.2 Stacking of units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6. Working with the ELAN 4 electro system . . . . . . . . . . . . . . . . . 8

6.1 System set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6.1.1 Connecting the accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6.1.2 Connecting the power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.1.3 Switching on the control unit. . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.1.4 Switching off the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.1.5 Putting out of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.1.6 Connecting the ELAN 4 electro to wireless foot control GA810 9

6.1.7 Connecting the ELAN 4 electro foot control GA808 to the

control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.1.8 Connecting the ELAN 4 electro motor cable

GA804/GA805/GA806 or ELAN 4 electro drill tool GA844 to

control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.1.9 Connecting the ELAN 4 electro single-use tube set GA395SU 10

6.1.10 Connecting the applied part to the motor cable. . . . . . . . . . . . 10

6.1.11 Releasing the applied part for operation ("On" position) . . . . . 11

6.1.12 Locking the applied part ("Off" position) . . . . . . . . . . . . . . . . . . 11

6.1.13 Disconnecting the applied part from the motor cable . . . . . . . 11

6.1.14 Disconnecting the ELAN 4 electro foot control GA808 from the

control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.1.15 Disconnecting the ELAN 4 electro motor cable

GA804/GA805/GA806 or ELAN 4 electro drill tool GA844 from

control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.2 Function checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.3 Safe operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.3.1 Activating the motor/pump control panel. . . . . . . . . . . . . . . . . 12

6.3.2 Changing the maximum speed setting/rotational direction of

the applied part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.3.3 Activating the coolant and irrigation pump/“Flush” function

(continuous flushing). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.3.4 Deactivating the coolant and irrigation pump and changing the

delivery rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.3.5 Enable application part using foot control GA808 or wireless

foot control GA810. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.3.6 Activating the applied part via hand control GA804/GA805 . 13

6.3.7 Activating the coolant pump via foot control . . . . . . . . . . . . . 13

6.4 System settings menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.4.1 User profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.4.2 Motor settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.4.3 Device settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.4.4 Wireless foot c1ontrol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.4.5 Device information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7. Reprocessing procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.1 General safety notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.2 Reusable products. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.3 Preparation before cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.4 Cleaning/disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.4.1 Product-specific safety instructions for the reprocessing

procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.5 Wipe disinfection for electrical equipment . . . . . . . . . . . . . . . 16

7.6 Inspection, maintenance and checks. . . . . . . . . . . . . . . . . . . . . 16

8. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

9. Troubleshooting list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

9.1 Display error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

9.1.1 System error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

9.1.2 Accessory error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

9.1.3 Operating error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

9.1.4 Other faults in control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

9.1.5 Faults when working with the applied part . . . . . . . . . . . . . . . 19

9.2 Fuse replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

10. Technical Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

11. Accessories/Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

11.1 ELAN 4 electro motor cables, applied parts and foot controls 21

11.2 Coolant and irrigation pump . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

11.3 Power cord. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

11.4 Equipotential bonding leads . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

11.5 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

12. Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

12.1 Classification according to Directive 93/42/EEC . . . . . . . . . . . 22

12.2 Performance data, information about standards . . . . . . . . . . . 22

12.3 Ambient conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

13. Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

14. Distributor in the US/Contact in Canada for product

information and complaints. . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Document No.: IFU - Version: 3.0 - Document ID: SOP-AIC-5001568 Date/Time Printed/Viewed: 2022-04-13 15:59 (CET)

Effective

6

USA

1. About this document

Note

General risk factors associated with surgical procedures are not described

in these instructions for use.

►Article-specific instructions for use and material compatibility infor-

mation can be obtained by visiting our website at www.aesculapusa-

ifus.com

1.1 Scope

This document describes all necessary instructions and steps for the pro-

vision, setting and safe operation of the ELAN 4 electro system and its

accessory components.

Additional instructions and steps regarding the accessory components, in

particular on their connection and reprocessing, can be found in the

respective instructions for use or supplement for the components.

1.2 Warnings

Warnings indicate hazards to patients, users and/or products that may

occur during the use of the product. Warnings are marked as follows:

DANGER

Indicates a potential danger. If it is not prevented, death or severe

injuries may result.

WARNING

Indicates a potential danger. If not prevented, minor or moderate inju-

ries may result.

CAUTION

Indicates a potential damage to property. If not prevented, the pro-

duct may be damaged.

2. General information

2.1 Intended use

The ELAN 4 electro control unit GA800 together with the accessory forms

an electrically operated motor system.

The ELAN 4 electro control unit GA800 supplies the energy and monitors

the motors in the ELAN 4 electro applied parts. The control unit receives

the speed request via the hand or foot control. The direction of rotation is

preselected by means of the foot control buttons, by means of the display

when using a hand control and by means of the pushers for the drill tool.

The purpose of the integrated coolant and irrigation pump is to deliver

coolant or irrigation fluid to the operating field for cooling the tool and

tissue or irrigating the operating field. It is activated via the buttons on the

foot control or via the display.

2.2 Application Environment

The motor system fulfills the requirements of Type BF in accordance with

IEC/DIN EN 60601-1.

For use in operating rooms, outside of the explosive hazard zone (e.g. areas

with highly pure oxygen or anesthetic gases).

2.3 Indications

The ELAN 4 Electro Motor System is intended for high speed cutting, saw-

ing, and drilling of bone in the fields of Spine, ENT, Neuro, and Maxillofa-

cial Surgery.

2.4 Contraindications

The ELAN 4 electro motor system is not authorized for use in the central

nervous system or central circulatory system.

Note

The safe and effective use of electrically driven applied parts depends heav-

ily on influences that only the user can control him or herself. Therefore the

specifications provided represent framework conditions only.

Note

The clinical success of the use of the ELAN 4 electro motor system is depen-

dent on the knowledge and experience of the surgeon. The surgeon must

decide which structures it is sensible to treat and take into account the

safety and warning information contained in these instructions for use.

3. Safe handling

CAUTION

Federal law restricts this device to sale by, or on order of a physician!

DANGER

Risk of death by electric shock!

►Do not open the product.

►Connect the product only to a grounded power supply

WARNING

Risk of injury and material damage due to inappropriate use of the

product!

►Use the product only in accordance with the intended use.

WARNING

Risk of injury and damage to property due to improper handling of the

product!

The ELAN 4 electro control unit GA800 together with the accessory

forms an electronically operated motor system.

►Follow the instructions for use of ELAN 4 electro accessories.

►Follow the instructions for use of all products used.

■General risk factors associated with surgical procedures are not

described in this documentation.

■It is the operating surgeon's responsibility to ensure that the surgical

procedure is performed correctly.

■The operating surgeon must have a thorough understanding of both the

hands-on and conceptual aspects of the established operating tech-

niques.

■The ELAN 4 electro control unit GA800 fulfills the requirements of

CISPR11, Class A.

►Inspect the new product after removing its transport packaging and

prior to first use to ensure it is in good working order.

►Observe “Notes on Electromagnetic Compatibility (EMC) for

ELAN 4 electro control unit GA800“ TA022452 , see Instructions for Use

at www.aesculapusaifus.com

►To prevent damage caused by improper setup or operation, and in order

not to compromise warranty and manufacturer liability:

– Use the product only according to these instructions for use.

– Follow the safety and maintenance instructions.

– Only combine Aesculap products with each other.

►Ensure that the product and its accessories are operated and used only

by persons with the requisite training, knowledge, or experience.

Maximum delivery rate of the pump 65 ml/min

Control unit

Application Environment In the unsterile area

Set-up location Table, ceiling supply unit, equipment cart,

or similar

Document No.: IFU - Version: 3.0 - Document ID: SOP-AIC-5001568 Date/Time Printed/Viewed: 2022-04-13 15:59 (CET)

Effective

7

USA

►Keep the instructions for use accessible for the user.

►Always adhere to applicable standards.

►Do not pull any of the cables by the actual cable but only by the con-

nector.

Note

The user agrees to report all serious incidents occurring in connection with

the product to the manufacturer and to the competent authority of the

country in which the user is registered.

4. Product description

4.1 Scope of supply

4.2 Components required for operation

■ELAN 4 electro control unit GA800

■Power cord, see Chapter 11.

■ELAN 4 electro motor cable for foot control GA806 and ELAN 4 electro

foot control GA808

–or–

■ELAN 4 electro motor cable with hand lever GA804 (from software ver-

sion 2.00)

–or–

■ELAN 4 electro motor cable with hand control GA805 (from software

version 2.00)

–or–

■ELAN 4 electro wireless foot control GA810 (software version 3.00 and

higher)

■ELAN 4 electro applied part

Note

The installed software version is displayed in the system settings menu in

the device information sub-item.

Contact the national B. Braun/Aesculap representative to upgrade the con-

trol unit to the current software version,see Chapter 10.

Note

The term “Applied part” comprises all handpieces and motors of the

ELAN 4 electro motor system, see Chapter 11.

When using the coolant and irrigation pump:

■Bottle holder GD412804

■Single-use tube set GA395SU

■Coolant or irrigation fluid: Physiological saline solutions up to 1 000 ml

Note

The coolant/irrigation fluid is not an Aesculap accessory.

4.3 Operating principle

4.3.1 Control unit

The ELAN 4 electro control unit 1is designed for main voltage ranges of

100 V~ to 120 V~ and 220 V~ to 240 V~ from 50 Hz to 60 Hz. The mains

voltage is converted into safety extra low voltage for supplying the micro

motors in the applied parts.

The control unit features two connection sockets for applied parts for con-

necting two different applied parts, and has one connection socket for a

foot control. Only one applied part can be operated at a time.

Note

The essential performance features are defined by the "speed" and "rota-

tional direction" specifications. The exception is a conditionally defined

motor stop to a safe state caused by a detected error condition

4.3.2 Display/control concept

The display 2indicates the current device status (operating and error sta-

tus) at all times. The display is divided into the applied part control panel

and the pump control panel.

The display shows the group of the applied part currently connected.

The display shows information about the speed, rotational direction, acti-

vation and delivery rate of the coolant and irrigation pump. By activating

the relevant panel, the control elements appear. Settings can then be

changed. If the control elements are not activated, they will disappear

again after a short time.

4.3.3 Explanation with an example

Note

If two applied parts are connected to the control unit, the display is divided

into 2/3 for the active applied part and 1/3 for the inactive applied part.

Fig.1 Example of control concept

Legend

aPump control panel

Selected delivery rate % (here 30 %)

bApplied part control panel

cApplied part type (here ELAN 4 electro high speed motor)

dActivation mode: (for foot control)

eQualitative bar display:

Display of the maximum set speed (white bar).

The actual current speed in the range from 0 to the maximum set

speed (green bar)

Difference between the maximum set speed and the upper limit of the

maximum speed (gray bar)

fMaximum set speed: (here 75 000 rpm)

gMaximum speed (uppermost limit) with this group: max. 80 000 rpm

hCall up the system settings menu

iRotational direction (here clockwise rotation)

Art. no. Designation

GA800 ELAN 4 electro control unit

GD412804 Bottle holder

SOP-AIC-

5001568

(TA014401)

Instructions for use of ELAN 4 electro control unit

c

b

a

d fe

i

gh

Document No.: IFU - Version: 3.0 - Document ID: SOP-AIC-5001568 Date/Time Printed/Viewed: 2022-04-13 15:59 (CET)

Effective

8

USA

4.3.4 Applied part types

The control unit recognizes the different types of applied parts (motors and

handpieces). These are shown in the display as a combination of symbol

and text. The size and display depend on which socket the applied part is

connected to and whether the applied part is active or locked.

4.3.5 Identification of control elements on system components

Control elements on the system components of the ELAN 4 electro motor

system are labeled with a gold marking.

4.3.6 Recognition of connected motor cable and applied part

The settings (upper speed limit, pump status and delivery volume) last

selected with this application part type on this bushing are retrieved upon

inserting the same application part type.

When several different hand/foot controls are connected to the control

unit, they are prioritized in the following order (higher items have priority

over lower):

■Hand controls GA804/GA805 or drill tool GA844

■Foot control GA808

■GA810 wireless foot control

4.3.7 Overload protection

To protect the micro motors in the applied parts against damage from

overheating, the motor temperature is monitored. If the temperature is too

high a warning signal sounds and a thermometer symbol appears in the

display 2.

If the temperature continues to be too high, the applied part is switched

off. The following message appears in the display 2: “The motor currently

being used is overheating. Please let the motor cool down or use another

suitable motor”.

After a cooling phase the applied part can be reactivated.

It is recommended to have a second applied part ready at hand.

4.3.8 Coolant and irrigation pump

The control unit is equipped with a coolant and irrigation pump 3.

The pump can be activated either in the corresponding pump control panel

or via the corresponding button on the foot control. It can be started by

activating the motor or via the “Flush” function (continuous flushing). The

delivery rate can only be adjusted via the pump control panel.

5. Preparation and setup

Non-compliance with the following instructions will preclude all respon-

sibility and liability in this respect on the part of Aesculap.

►When setting up and operating the product, adhere to

– national regulations for installation and operation,

– national regulations on fire and explosion protection.

Note

For the safety of patients and users it is essential that the mains power cord

and, especially, the protective earth connection are intact. In many cases

defective or missing protective earth connections are not registered imme-

diately.

►Connect the device via the potential equalization terminal at the rear

panel of the device to the potential equalization system of the room

used for medical purposes.

Note

The potential equalization lead can be ordered from the manufacturer as

art. no. GK535 (4 m length) or TA008205 (0.8 m length).

5.1 Set-up environment/set-up location

DANGER

Fire and explosion hazard!

►Use the product outside of explosion hazard zones (e.g. areas with

highly pure oxygen or anesthetic gases).

The ELAN 4 electro control unit is authorized for operation in the operat-

ing room.

Note

After being installed and put into operation, the control unit must not be

transported or moved to a different set-up location.

Note

The control unit must not be placed on an Aesculap mobile stand (GA415,

GA416 and GD416M).

►Make certain that the ventilation slots in the bottom of the housing

and in the rear panel of the control unit are not covered, e.g. by an OR

cloth.

►Make certain that the control elements, mains power switch and power

socket 13 are freely accessible for the user.

►Make certain the system is set up on a sufficiently stable support (e.g.

a table, ceiling support, equipment cart, etc.).

►Follow the instructions for use of the support.

5.2 Stacking of units

►Do not exceed a stack height of 415 mm.

►Place the units in a stable position.

►Aesculap devices must be stacked on top of each other facing identi-

cally.

►Never move stack devices.

6. Working with the ELAN 4 electro sys-

tem

6.1 System set-up

WARNING

Risk of injury and material damage due to inadvertent activation of

the applied part!

►Secure applied parts that are not actually used against inadvertent

activation ("Off" position), see section on locking applied part

("Off" position).

6.1.1 Connecting the accessories

Combinations of accessories that are not mentioned in the present

instructions for use may only be employed if they are specifically intended

for the respective application, and if they do not compromise the perfor-

mance and safety characteristics of the products.

Also note that any equipment connected at the interfaces must demon-

strably meet the respective IEC standards (e.g. IEC 60950 for data process-

ing equipment, IEC/DIN EN 60601-1 for electromedical devices).

All configurations must fulfill the basic standard IEC/DIN EN 60601-1. Any

individual connecting devices with one another is responsible for such

configuration and must ensure compliance with basic standard IEC/DIN

EN 60601-1 or applicable national standards.

►Follow the instructions for use of individual accessories.

►In case of questions, contact your B. Braun/Aesculap partner or

Aesculap Technical Service, Address see Chapter 10.

Document No.: IFU - Version: 3.0 - Document ID: SOP-AIC-5001568 Date/Time Printed/Viewed: 2022-04-13 15:59 (CET)

Effective

9

USA

6.1.2 Connecting the power supply

DANGER

Risk of death by electric shock!

►Connect the product only to a grounded power supply.

Note

The mains voltage must correspond to the voltage indicated on the type

plate at the back of the unit.

►Plug in the power cord at power cord socket 13.

►Connect power supply by inserting into a wall socket.

6.1.3 Switching on the control unit

►Activate the power ON switch 10.

The power ON indicator 9and indicator light 5light up.

The control unit 1always performs a power-on self-test when the unit

is switched on.

If a malfunction is detected, an error message will appear in the

display 2, see system errors.

6.1.4 Switching off the control unit

►Activate the power OFF switch 8.

The power ON indicator 9, the indicator light 5and the display with

touch control panel 2will fade out.

6.1.5 Putting out of operation

Note

The safe and all-pole disconnection of the product from the main power

supply is only guaranteed when the power cord is unplugged.

►Switching off the product: Activate the power OFF switch 8.

►Unplug the power cord from the power socket 13.

The operation of the device is safely terminated.

6.1.6 Connecting the ELAN 4 electro to wireless foot control

GA810

The system configuration menu is used to connect the wireless foot con-

trol to the control unit, see Chapter 6.4.4

6.1.7 Connecting the ELAN 4 electro foot control GA808 to the

control unit

Note

The plug connection of the foot control has a yellow coded ring and a filled-

in dot.

►Position connector of foot control cso that marking bon the connector

is aligned with marking aon the connection socket for foot control 6,

see Fig.2.

►Plug the connector for foot control cfirmly into the connection socket

for foot control 6.

Fig.2 Connecting the foot control

Legend

aMarking for connection socket

bMarking for connector

cConnector for foot control

a

b

c

Document No.: IFU - Version: 3.0 - Document ID: SOP-AIC-5001568 Date/Time Printed/Viewed: 2022-04-13 15:59 (CET)

Effective

10

USA

6.1.8 Connecting the ELAN 4 electro motor cable

GA804/GA805/GA806 or ELAN 4 electro drill tool GA844 to

control unit

Note

The motor cable is sterile. Sterile separation occurs at the motor cable.

Note

The plug connection of the motor cable has a blue coded ring and a hollow

dot.

►Position connector for control unit con the motor cable so that mark-

ing bon the connector is aligned with marking aon the connection

socket for applied parts 7, see Fig.3.

►Plug connector for control unit con the motor cable firmly into one of

the two connection sockets for applied parts 7.

Fig.3 Connecting the motor cable

Legend

aMarking for connection socket

bMarking for connector

cConnector for control unit

Note

The motor cable must be connected to the control unit without an applied

part or with the applied part locked ("Off" position).

Otherwise the control unit will not recognize the applied part, and a mes-

sage will appear on the display (except for drill tool GA844).

►If the applied part is not recognized;

– Lock the applied part, see Chapter 6.1.12.

– Release the applied part again, see Chapter 6.1.11.

6.1.9 Connecting the ELAN 4 electro single-use tube set GA395SU

Note

The tube set is sterile. Sterile separation occurs at the tube set.

►Open flap aof the coolant and irrigation pump 3, see Fig.4.

►Insert single-use tube set c:

– Place pump tube with loop over the roller wheel b.

– Push nib eof the single-use tube set under the pull slide duntil the

nib engages.

►Close flap of the coolant and irrigation pump a. When doing this, make

certain the pump tube does not get clamped in.

►Insert the bottle holder 16 for the sterile fluid bottle in bottle holder

mount 15.

►Insert the punching spike into the sterile fluid bottle.

►When using sterile fluid bottles made from glass: Open the ventilation

flap on the punching spike.

►Hang the sterile fluid bottle from the bottle holder 16.

►Fasten the tube to the motor cable using fixation clamps.

►Shorten the length of the tubes to correspond with the applied part

being used and connect to the spray nozzle.

Fig.4 Connecting the single-use tube set

Legend

aFlap of the coolant and irrigation pump

bRoller wheel

cSingle-use tube set

dPull slide

eNib of the single-use tube set

6.1.10 Connecting the applied part to the motor cable

Note

All ELAN 4 electro motor cables (GA804/GA805/GA806) can be used in

combination with all applied parts that do not have a fixed connection with

a cable.

►Connect connector for motor cable 24 to connector for application

part 19 of the motor cable. Ensure that the nose 23 on the motor cable

is aligned with the groove on the coupling of the application part.

The applied part engages. When the visual field is “Off” 20 on the

motor cable, a gold-colored marking is visible.

The control unit 1recognizes the applied part type and displays this

type in the corresponding applied part control panel in the display 2.

The most recent settings for this applied part type at the same motor

connection socket are shown on the display 2.

Note

The applied part connected to this motor cable is only ready for operation if

a gold-colored marking is visible in the visual field "On" 21 on the motor

cable.

a

b

c

a

b

c

d

e

Document No.: IFU - Version: 3.0 - Document ID: SOP-AIC-5001568 Date/Time Printed/Viewed: 2022-04-13 15:59 (CET)

Effective

11

USA

6.1.11 Releasing the applied part for operation ("On" position)

Note

The operation of the drill tool GA844 is different. Refer to drill tool instruc-

tion manual GA844 [SOP-AIC-5002244 (TA014436)].

►Activate the release button 22 on the motor cable and push the applied

part further onto the motor cable.

The applied part engages. When the visual field is “On” 21 on the motor

cable, a gold-colored marking is visible.

Note

For applied parts with slider for tool release 25, in the "On" position 21 the

nib 23 on the motor cable blocks the slider. Uncoupling of the tools is there-

fore only possible in "Off" position 20.

For applied parts with unlocking sleeve 26, in the "On" position 21 the con-

nection for applied part 19 on the motor cable blocks the unlocking sleeve.

Uncoupling of the attachments is therefore only possible in "Off"

position 20.

For applied parts without slider for tool release, it is possible to cou-

ple/uncouple tools in the "On" position, but this must not be done due to the

risk of injury from unintentional activation of the applied part.

6.1.12 Locking the applied part ("Off" position)

Note

The operation of the drill tool GA844 is different. Refer to drill tool instruc-

tion manual GA844 [SOP-AIC-5002244 (TA014436)].

►Activate the release button 22 on the motor cable and detach the

motor cable from the applied part.

The applied part engages. When the visual field is “Off” 20 on the

motor cable, a gold-colored marking is visible.

6.1.13 Disconnecting the applied part from the motor cable

►Activate the release button 22 on the motor cable and pull at the con-

nection for applied part 19 to disconnect the motor cable from the

applied part.

6.1.14 Disconnecting the ELAN 4 electro foot control GA808 from

the control unit

►Unplug connector for foot control cfrom the connection socket for

foot control 6, see Fig.2.

6.1.15 Disconnecting the ELAN 4 electro motor cable

GA804/GA805/GA806 or ELAN 4 electro drill tool GA844

from control unit

►Unplug the motor cable on the connector for control unit cfrom the

connection socket for applied parts 7, see Fig.3.

6.2 Function checks

►Prior to each use and after every change of applied part, check that all

products to be used are in good working order.

►Check the secure connection of all products to be used.

►Ensure that the parameters are set and the unit is operated according

to the instructions for use and the safety information for the applied

parts or tools.

►Check that the cutting edges of the tools are not showing any mechan-

ical damage.

►Check that the correct applied part type for the applied parts con-

nected is showing in the corresponding applied part control panel in

the display.

►Do not use the product if it is damaged or defective. Set aside the pro-

duct if it is damaged.

►Release the applied part for operation.

►Activate the foot or hand control down to the limit stop.

The applied part starts running in the preselected rotational direction

and reaches the maximum speed as indicated in the applied part con-

trol panel in the display.

The applied part runs quietly at a constant speed.

The qualitative bar display for the actual current applied part speed in

the applied part control panel is fully illuminated.

►If necessary, release the coolant and irrigation pump in the correspond-

ing applied part control panel or by pressing the function button on the

foot control.

The coolant and irrigation pump starts as soon as the applied part is

operated.

6.3 Safe operation

WARNING

Risk of injury and/or malfunction!

►Always carry out a function check prior to using the product.

WARNING

Risk of injury and material damage due to inadvertent activation when

repositioning/moving the foot control!

►To reposition the foot control: Use a transport brace.

►Prior to repositioning: Secure the applied part against inadvertent

activation ("Off" position).

It is only possible to operate the applied part and change the setting

parameters on the control unit if:

■the applied part is connected to the control unit by a motor cable,

■a foot control is connected to the connection socket for foot control 6

(when using the ELAN 4 electro motor cable GA806),

■there is no second applied part released at the same time and

■the applied part type is shown on the display of the control unit.

The following motor settings of the applied part cannot be changed when

the applied part is running:

■Rotational direction (except for GA844, via pusher for rotational direc-

tion)

■Maximum speed

Document No.: IFU - Version: 3.0 - Document ID: SOP-AIC-5001568 Date/Time Printed/Viewed: 2022-04-13 15:59 (CET)

Effective

12

USA

6.3.1 Activating the motor/pump control panel

Note

Motor settings of applied parts that are not connected to a cable cannot be

changed while the applied part is running.

►Changing the setting parameters of the applied part: Activate the

applied part control panel bin the display 2, see Fig.5.

►Changing the setting parameters of the coolant and irrigation pump:

Activate the pump control panel ain the display 2.

The activated control panel switches to the Settings mode. Now the

setting parameters listed below can be changed.

Fig.5 Activating the control panel

Legend

aPump control panel

bApplied part control panel

6.3.2 Changing the maximum speed setting/rotational direction of

the applied part

►Activate the applied part control panel, see Chapter 6.3.1.

►Change direction of rotation (except for drill tool GA844): Actuate the

inactive, grey clockwise/counterclockwise rotation button a/b, see

Fig.6.

The rotational direction is changed from clockwise rotation to counter-

clockwise rotation and vice versa.

►Change speed range limit: Press the buttons to reduce/increase the

speed range limit c/dor the speed range limit switch 31 on the wireless

foot switch.

The maximum speed setting is reduced/increased by increments.

Note

The increments for changing the maximum speed setting depend on the

applied part connected.

Fig.6 Changing the maximum speed setting/rotational direction

Legend

aRotational direction button for counterclockwise rotation

bRotational direction button for clockwise rotation

cButton for reducing the maximum speed setting

dButton for increasing the maximum speed setting

6.3.3 Activating the coolant and irrigation pump/“Flush” function

(continuous flushing)

►Activate the pump control panel, see Chapter 6.3.1.

►Activate the coolant and irrigation pump: Activate the button for

switching on the irrigation pump a, see Fig.7.

The coolant and irrigation pump is active and delivers coolant or irri-

gation fluid at the currently set delivery rate.

►Activate the "Flush" function: Activate and hold down the "Flush"

button b.

The "Flush" function is now active. The coolant and irrigation pump

delivers coolant or irrigation fluid at the maximum delivery rate until

the "Flush" button bis released.

Note

The activation of the "Flush" function does not depend on whether an

applied part is connected or activated.

Fig.7 Activating the coolant and irrigation pump/“Flush” function

Legend

aButton for switching the coolant and irrigation pump on/off

b"Flush" button

cButton for reducing the delivery rate

dButton for increasing the delivery rate

6.3.4 Deactivating the coolant and irrigation pump and changing

the delivery rate

Note

The delivery rate of the coolant and irrigation pump can only be changed

when the irrigation pump is activated.

►Activate the pump control panel, see Chapter 6.3.1.

►Deactivate the coolant and irrigation pump: Activate the button for

switching off the irrigation pump a, see Fig.7.

The coolant and irrigation pump is inactive and no longer delivers cool-

ant.

►Change the delivery rate: Activate the buttons for reducing/increasing

the delivery rate c/d.

The delivery rate of the coolant and irrigation pump is

reduced/increased by increments.

The delivery rate can be adjusted in the following increments:

■1 % to 5 %: 1 % increments

■5 % to 100 %: 5 % increments

b

a

abcd

abcd

Document No.: IFU - Version: 3.0 - Document ID: SOP-AIC-5001568 Date/Time Printed/Viewed: 2022-04-13 15:59 (CET)

Effective

13

USA

6.3.5 Enable application part using foot control GA808 or wireless

foot control GA810

Note

Applied parts connected to a hand control cable cannot be operated via the

foot control.

Note

When an applied part is plugged in, clockwise rotation is always pre-set.

To activate clockwise rotation:

►Set the rotational direction button for motor 30 to clockwise rotation.

The motor direction indicator for clockwise rotation is illuminated in

the applied part control panel.

►Activate the pedal 29.

The applied part rotates clockwise.

To activate counterclockwise rotation:

►Set the rotational direction button for motor 30 to counterclockwise

rotation.

The motor direction indicator for counterclockwise rotation is illumi-

nated in the applied part control panel.

►Activate the pedal 29.

The applied part runs counterclockwise.

The control unit emits an acoustic signal.

Set rotary speed range limit (for wireless foot control GA810):

►Actuate the switch for speed range limit 31.

6.3.6 Activating the applied part via hand control GA804/GA805

Note

When an applied part is plugged in, clockwise rotation is always pre-set.

To activate clockwise rotation:

►Set the motor direction to clockwise rotation on the control unit.

The motor direction indicator for clockwise rotation is illuminated in

the applied part control panel.

►Activate the control element of the hand control.

The applied part runs clockwise.

To activate counterclockwise:

►Set the motor direction to counterclockwise rotation on the control

unit.

The motor direction indicator for counterclockwise rotation is illumi-

nated in the applied part control panel.

►Activate the control element of the hand control.

The applied part rotates counterclockwise.

The control unit emits an acoustic signal.

6.3.7 Activating the coolant pump via foot control

►Switch the coolant and irrigation pump on/off: Briefly activate func-

tion button 28.

►Activate the “Flush” function (continuous flushing): Activate the func-

tion button 28 for a longer period and keep pressed down.

6.4 System settings menu

Note

The system settings menu can only be called up when no applied part is

being operated.

While the system settings menu is active, the operation of the applied part

is blocked.

►Call up the system settings menu: Activate the button for the system

settings menu h, see Chapter Fig.1.

The system settings menu opens, see Fig.8.

Fig.8 System settings menu

Legend

a“Exit system settings” button

b“user profiles” button

c“motor settings” button

d“device settings” button

e“radio footcontrol” button

f“device information” button

►Call up menu: Activate the menu button.

►Exit system configuration menu: Press “Exit configuration menu” a

button.

Menu Description

user profiles Manage user profiles

motor settings Display and change the settings for the indi-

vidual applied part types

device settings Display and change the basic settings for the

control unit

radio footcontrol Connect/disconnect the GA810 wireless foot

control

device information Display information about the control unit

b

a

c

d

e

f

Document No.: IFU - Version: 3.0 - Document ID: SOP-AIC-5001568 Date/Time Printed/Viewed: 2022-04-13 15:59 (CET)

Effective

14

USA

6.4.1 User profiles

User profiles can be created and edited in the user profiles menu.

Note

When the control unit is restarted, the default profile is loaded automati-

cally.

Fig.9 User profiles

Legend

aExit menu

bUser profile button

cImport/export user profiles from/to USB stick

dDelete user profile

eModify user profile

fCreate user profile

►Exit menu: Press “Exit menu” abutton.

►Select user profile: Press the user profile bbutton.

The active user profile is highlighted in black.

►Create user profile:

– Press button “Create user profile” f.

– Enter the name of the user profile.

The settings below can be made for every user profile:

– Motor settings

– Device settings

– Oscillation settings (only for drill tool GA844)

►Modify user profile: Press button “Modify user profile” e.

►Delete user profile: Press button “Delete user profile” d.

►Import/export user profiles from/to USB stick:

– Inset USB stick into USB port of the control unit.

– Press button “import/export of profiles” c.

– Press button “import” or “export”.

– Follow the instructions on the display.

Note

Profiles must be saved after creation or modification.

►Save Profile: Press button .

6.4.2 Motor settings

The motor settings menu displays the applied part types, see Fig.10.

Fig.10 Motor settings – Overview of applied part types

Legend

aExit menu

bButtons for the types of applied parts

►Exit menu: Press “Exit menu” abutton.

►View/change the motor settings of a type of applied part: Press the type

of applied part bbutton.

The submenu for the applied part type selected opens, see Fig.11.

Fig.11 Motor settings – Selected applied part type

Legend

aFactory reset

bFlow rate of the coolant and irrigation pump

cSlow down rate of the applied part

dSpeed up rate of the applied part

eMaximum speed (maximum speed/stroke rate)

fLeave menu

gReduce value

hIncrease value

►Leave menu: Press button “Leave menu” f.

►Change motor settings: Press button “Reduce value” hor “Increase

value” g.

The change is implemented immediately. The set value is displayed.

ed f

a

b

c

a

b

e

d

c

b

a

gh

f

Document No.: IFU - Version: 3.0 - Document ID: SOP-AIC-5001568 Date/Time Printed/Viewed: 2022-04-13 15:59 (CET)

Effective

15

USA

►Reset motor settings to default settings

– Press button “Factory reset” a.

– Confirm message.

Drill tool GA844

The settings below are additionally available for the drill tool GA844:

6.4.3 Device settings

Fig.12 Device settings

Legend

aExit menu

bSet system volume

cSetting display brightness

dReset system volume and brightness to default settings

eSet system language

fReduce value

gIncrease value

►Exit menu: Press Exit menu abutton.

►Change system volume/brightness: Press button “Increase value” gor

“Reduce value” f.

The change is implemented immediately. The set value is displayed.

►Set system language:

– Press button “language” e.

– Select desired language.

►Reset system volume and brightness to default settings

– Press button “factory reset” a.

– Confirm message.

6.4.4 Wireless foot c1ontrol

The wireless foot control GA810 can be connected to the control unit or

disconnected from the control unit via the menu “radio footcontrol”.

Fig.13 Wireless foot control settings

Legend

aConnect wireless foot control (or disconnect if a wireless foot control

is connected)

►Connect the GA810 wireless foot control:

– Select Connect to GA810 button and

– follow the instructions on the display. Compare the serial number

in the control unit display to the

– serial number of the wireless foot control and select "Yes" to con-

firm the message.

►Disconnect the GA810 wireless foot control

– by pressing the “Disconnecting from GA810” button

– or–

– switch off the control unit for approx. 10 min.

6.4.5 Device information

The “device information” menu displays general information about the

device and the device software.

►Leave the menu: Activate the “Leave menu” ebutton.

7. Reprocessing procedure

7.1 General safety notes

Note

Adhere to national statutory regulations, national and international stan-

dards and directives, and local, clinical hygiene instructions for reprocess-

ing.

Note

For patients with Creutzfeldt-Jakob disease (CJD), suspected CJD, or possi-

ble variants of CJD, observe the relevant national regulations concerning

the reprocessing of products.

Note

It should be noted that successful reprocessing of this medical device can

only be guaranteed following prior validation of the reprocessing method.

The operator/reprocessing technician is responsible for this.

Setting Description

Oscillation mode Determines whether the oscillation function

on the drill can be activated.

Oscillation angle Total oscillation angle

Thread cutting operation

angle left

Thread cutting operation angle counter-

clockwise

Thread cutting operation

angle right

Thread cutting operation angle clockwise

a

b

c

d

e

fg

a

Document No.: IFU - Version: 3.0 - Document ID: SOP-AIC-5001568 Date/Time Printed/Viewed: 2022-04-13 15:59 (CET)

Effective

16

USA

7.2 Reusable products

The service life of the product is limited by damage, normal wear, type and

duration of the application, handling, storage and transportation of the

product.

Careful visual and functional testing prior to next use is the best way to

identify a malfunctioning product.

7.3 Preparation before cleaning

►Separate the products from each other immediately after use.

►Shut down control unit 1immediately after use, see Chapter 6.1.5.

►Remove any visible surgical residues as much as possible with a damp,

lint-free cloth.

7.4 Cleaning/disinfection

7.4.1 Product-specific safety instructions for the reprocessing pro-

cedure

DANGER

Risk of electric shock and fire hazard!

►Unplug the device before cleaning.

►Do not use flammable or explosive cleaning or disinfecting solu-

tions.

►Ensure that no fluids will penetrate the product.

CAUTION

Damage to, or destruction of the product caused by mechanical clean-

ing/disinfection!

►Clean the product with wipe disinfection only.

►Do not sterilize the product under any circumstances.

CAUTION

Damage to the product due to inappropriate cleaning/disinfecting

agents!

►Only use cleaning/disinfecting agents approved for surface clean-

ing. Follow the manufacturer’s instructions for the respective

cleaning/disinfecting agent.

►Do not clean the product in a ultrasonic bath and do not immerse the

product in any fluids.

7.5 Wipe disinfection for electrical equipment

RT: Room temperature

* Recommended: Meliseptol® wipes sensitive (B. Braun)

Phase I

►Remove any visible residues with a disposable disinfectant wipe.

Phase II

►Wipe all surfaces of the optically clean product with a fresh, disposable

disinfectant wipe.

►Observe contact time requirements (at least 1 min).

7.6 Inspection, maintenance and checks

►Inspect the product after each cleaning and disinfecting cycle to be

sure it is: clean, functional, and undamaged.

►Set aside the product if it is damaged.

8. Maintenance

To ensure reliable operation, the product must be maintained at least once

a year.

Contact your national B. Braun/Aesculap representative if you need these

services, see Chapter 10.

Phase Step T

[°C/°F]

t

[min]

Conc.

[%]

Water quality Chemicals

I Cleaning RT 1 - - 17 % Propan-1-ol,

0.23 % Didecyldimethylammonium chloride*

II Wipe disinfection RT ≥1 - - 17 % Propan-1-ol,

0.23 % Didecyldimethylammonium chloride*

Document No.: IFU - Version: 3.0 - Document ID: SOP-AIC-5001568 Date/Time Printed/Viewed: 2022-04-13 15:59 (CET)

Effective

17

USA

9. Troubleshooting list

►Have defective products repaired by Aesculap Technical Service, see

Chapter 10.

9.1 Display error messages

Faults that are recognized by the control unit are shown as error messages

in the display.

There are three types of error messages:

■System error (text in red field): It is not possible to work with the con-

trol unit or system.

■Accessory error (text in yellow field): It is possible to work with a dif-

ferent component.

■Operating error (text in blue field): It is possible to work with the sys-

tem after rectifying the cause of the error.

Note

Many faults cannot be clearly categorized. They can be caused by an oper-

ating error or an accessory error. In such cases, an operating error is

assumed first, to avoid any unnecessary changing or sending in of new

products.

9.1.1 System error

9.1.2 Accessory error

Message displayed Cause Remedy

System error

Switch the control unit off and on.

If the error re-occurs, replace the control unit.

The internal monitoring of the control unit

recognizes an error or fault.

Switch the control unit off and on again.

If the message appears again: Replace the control

unit.

Message displayed Cause Remedy

Motor or motor cable could be damaged Motor cable or applied part defective Replace motor cable or applied part.

Malfunction of foot control

If this message is displayed frequently, please per-

form a technical inspection on the foot control

Foot control defective Replace foot control.

Critical Foot Control Error

Unexpected error occurred in the area of the foot

control. If this message does not disappear auto-

matically, please restart the device.

Foot control defective Replace foot control.

Critical error in manual control module

Unexpected error occurred in the area of the hand

control. If this occurs repeatedly, please replace

the hand control.

Unexpected error in the area of the hand con-

trol

Restart device

Hand control defective Replace hand control.

Prohibited combination of accessories

A prohibited combination of motor and cable cod-

ing was found on socket 1/socket 2.

A prohibited combination of application part

and motor cable is connected to the control

unit.

Check inserted products and replace with a per-

missible combination of application part and

motor cable as applicable.

Motor not recognized

It was impossible to recognize the motor type.

Please replace the motor. If this does not work,

replace the motor cable as well.

Wrong applied part

Applied part defective

Change applied part.

Motor cable defective Replace motor cable.

Unknown motor type

Please verify that the software version of the

device is suitable for this motor type.

Software version of the control unit is incom-

patible with the application part used.

Verify software version of the control unit.

Have control unit software updated by Technical

Service.

Motor overheated

The motor currently being used is overheating.

Please let the motor cool down or use another suit-

able motor.

Motor of the applied part has overheated Allow the applied part to cool down.

If the applied part overheats excessively: Replace

the applied part.

Motor blocked

Stop motor actuation and release blockage

If the error re-occurs, replace the product.

Applied part blocked Stop applied part actuation and release blockage.

If the error occurs when the applied part is running

idle: Replace the applied part.

Document No.: IFU - Version: 3.0 - Document ID: SOP-AIC-5001568 Date/Time Printed/Viewed: 2022-04-13 15:59 (CET)

Effective

This manual suits for next models

1

Table of contents

Other Aesculap Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual