Aesculap PV481 Manual

Aesculap®

Aesculap Endoscopic Technology

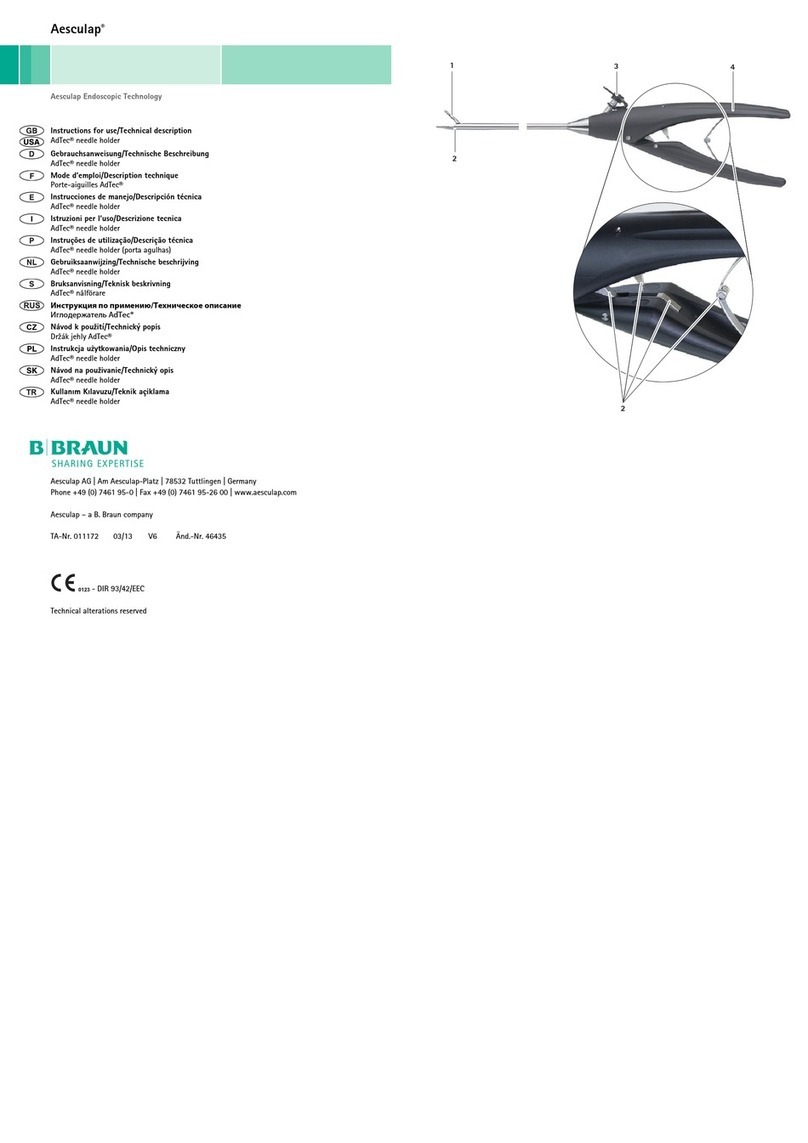

Instructions for use/Technical description

2D camera heads PV481, PV482, PV485

Gebrauchsanweisung/Technische Beschreibung

2D-Kameraköpfe PV481, PV482, PV485

Mode d’emploi/Description technique

Têtes de caméra 2D PV481, PV482, PV485

Instrucciones de manejo/Descripción técnica

Cabezales de cámara 2D PV481, PV482, PV485

Istruzioni per l’uso/Descrizione tecnica

Testa per telecamera 2D PV481, PV482, PV485

Instruções de utilização/Descrição técnica

Cabeças de câmara 2D PV481, PV482, PV485

Gebruiksaanwijzing/Technische beschrijving

2D camerakoppen PV481, PV482, PV485

Bruksanvisning/Teknisk beskrivning

2D-kamerahuvuden PV481, PV482, PV485

Инструкция по примению/Техническое описание

2D-головки камер PV481, PV482, PV485

Návod k použití/Technický popis

2D hlavy kamery PV481, PV482, PV485

Instrukcja użytkowania/Opis techniczny

Głowice z kamerą 2D PV481, PV482, PV485

Návod na použitie/Technický opis

2D hlavy kamery PV481, PV482, PV485

Kullanım Kılavuzu/Teknik açiklama

2D kamera kafaları PV481, PV482, PV485

사용 설명서 /기술 설명

2D 카메라 헤드 PV481, PV482, PV485

123 4

4

2

1

5

PV482/PV485

PV481

2

Aesculap®

2D camera heads PV481, PV482, PV485

Aesculap®

2D camera heads PV481, PV482, PV485

Legend

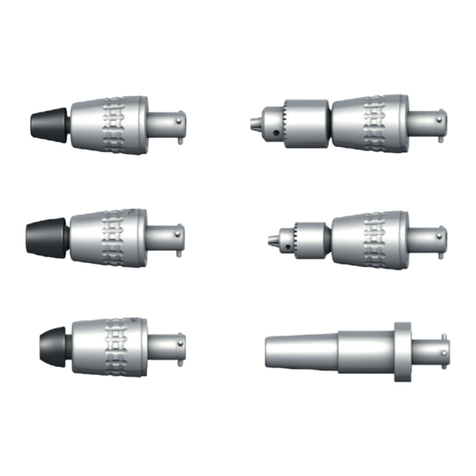

1Endocoupler

2Focus ring

3Zoom ring

4Camera head buttons

5Lock

Symbols on product and packages

Contents

1. Applicable to. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Safe handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Scope of supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Components required for operation . . . . . . . . . . . . . . . . . . . . . . 5

3.3 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.4 Operating principle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4. Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1 Combination with medical electrical equipment. . . . . . . . . . . . 7

4.2 Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3 First use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5. Working with the camera heads . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1 General notes on use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.2 System set-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.3 Function checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.4 Safe operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6. Reprocessing procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.2 Dismantling prior to carrying out the reprocessing procedure. 11

6.3 Preparations at the place of use . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.4 Preparation before cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.5 Cleaning/disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.6 Manual cleaning and disinfecting. . . . . . . . . . . . . . . . . . . . . . . . 12

6.7 Mechanical cleaning/disinfecting with manual pre-cleaning . 14

6.8 STERRAD sterilisation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.9 Material-compatible cleaning and disinfecting agents. . . . . . . 16

6.10 Inspection, maintenance and checks . . . . . . . . . . . . . . . . . . . . . 16

6.11 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7. Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

WARNING

Indicates a hazard. If not avoided, the hazard can result

in death or serious injury.

CAUTION

Indicates a potential hazard. If not avoided, this hazard

may result in injury and/or damage to the product.

Follow the instructions for use

Caution (IEC 60601-1 3rd edition) / Attention, please

take note of the accompanying document (IEC 60601-

1 2nd edition)

Defibrillation-proof type CF rated part according to

IEC 60601-1

Permissible storage temperature

Permissible relative air humidity during storage

Permissible atmospheric pressure during storage

Not permitted for use in a magnetic resonance environ-

ment

Caution, fragile

Article number

Serial number

REF

SN

Manufacturer

Date of manufacture

Federal Law (US) restricts this device to sale to or on

behalf of a physician

Marking of electric and electronic devices according to

directive 2002/96/EC (WEEE). see Disposal

3

8. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

9. Troubleshooting list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

9.1 Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

10. Technical Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

11. Accessories/Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

12. Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

12.1 Ambient conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

13. Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

14. Distributor in the US/Contact in Canada for product

information and complaints. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1. Applicable to

These instructions for use apply to the following devices:

These instructions for use are an integral component of the device and

contain all the information required by users and operators for safe and

proper use.

Target group

These instructions for use are intended for physicians, medical assistants,

medical technicians and employees of sterile services who are entrusted

with the installation, operation, maintenance and reprocessing of the

device.

Using and storing this document

These instructions for use must be stored in a defined location so that it

may be accessed at all times by the target group.

In the event of the sale of this device or its relocation, this document must

be handed over to the new owner.

Supplementary documents

For the use and assignment of the camera head buttons and the related

options and possible functions, observe the instructions for use of the

camera control unit concerned.

The instructions for use of the camera head used and instructions for use

of all other devices used must be observed to ensure the safe use of the

device.

►For item-specific instructions for use and information regarding mate-

rial compatibility, see Aesculap Extranet at

https://extranet.bbraun.com

2. Safe handling

CAUTION

Federal law restricts this device to sale by, or on order of a physician!

Designation Art. no.

Full HD CMOS camera head with pendulum coupler PV481

Full HD CMOS camera head with zoom coupler PV482

Full HD 3CMOS camera head with zoom coupler PV485

WARNING

Risk to user and patient from non-observance of

instructions, warnings and precautions!

►Use the product only according to these instruc-

tions for use.

►Check the product is in good working order

before use.

►Carry out function checks before each use.

►Do not use the product if irregularities are

observed during inspections and checks.

WARNING

Risk to patient due to incorrect application!

►Use the product only after instruction by the

manufacturer or by an authorized person.

►The instructions for use enclosed with the indi-

vidual components and all products used (e.g.

high frequency surgery) must be observed.

►Endoscopic procedures may only be carried out

by specialists who have the necessary medical

training, knowledge and experience.

WARNING

Risk to patient and user due to premature wear!

►Handle and maintain the product properly.

►Use the product only in accordance with the

intended purpose.

CAUTION

Possible restricted function if third party devices

are used!

►Use the product with the recommended compo-

nents and accessories.

►The full functionality of the product can only be

guaranteed if the recommended accessory com-

ponents are used.

4

Aesculap®

2D camera heads PV481, PV482, PV485

Note

Accessories and/or peripheral devices which are connected to the inter-

faces of the medical device must be verified to comply with the relevant

specifications (e.g. IEC 60601-1).

Note

The medical electrical device may not be modified in any way.

Note

To guarantee optimal function of the product, use in controlled environ-

mental conditions is recommended (e.g. air-conditioned operating room).

Note

Always handle the medical device very carefully as it contains sensitive

optic, mechanic and electronic components. Do not strike or drop the cam-

era head.

Note

Ensure that all devices operated in the vicinity meet their relevant EMC

requirements.

Note

The camera components are used to visualize the inside of the body during

minimally invasive procedures. Do not use the components for diagnostic

purposes. This applies in particular with the use of image optimization

algorithms.

Note

Before putting into operation, check the compatibility of all components

using the accessories list.

Note

All accessories and spare parts must only be procured from the manufac-

turer.

►Remove the transport packaging and clean the new product, either

manually or mechanically, prior to its initial sterilization.

►Prior to use, check that the product is in good working order.

►Observe “Notes on Electromagnetic Compatibility (EMC)“, see

TA022130.

►To prevent damage caused by improper setup or operation, and in order

not to compromise warranty and manufacturer liability:

– Use the product only according to these instructions for use.

– Follow the safety and maintenance instructions.

– Only combine Aesculap products with each other.

– Follow the application advisories acc. to standard, see Extracts from

relevant standards.

►Ensure that the product and its accessories are operated and used only

by persons with the requisite training, knowledge, or experience.

►Keep the instructions for use accessible for the user.

►Always adhere to applicable standards.

WARNING

Risk of injury due to electric shock!

►When installing a medical electrical system,

there is a risk of fire, short-circuit or electric

shock. Installation must be performed by quali-

fied personnel only.

►If a number of electrical devices are being used

in combination, observe Annex I of IEC 60601-

1:2006. Non-medical devices that comply with

the applicable IEC safety standards can be con-

nected only via a medical isolating transformer.

Do not connect any additional non-medical

devices to a medical electrical system.

►Signal lines from devices with a functional con-

nection, which are connected to different

branches of the mains power supply, must be

galvanically isolated at both ends.

►Connect the devices only to a power supply with

a protective earth conductor.

►After installing a medical electrical system, it

must be inspected according to IEC 62353.

WARNING

Risk to the patient if the product is not used gen-

tly/a damaged product is used!

►Handle the product with appropriate care.

►Do not use the product if it has been subjected

to strong mechanical stress or if it has been

dropped, and send the product to the manufac-

turer or an authorized repair center for inspec-

tion.

WARNING

Risk to patient if the device power fails!

►Use the device only with an uninterruptible

power supply.

►To guarantee a continuous power supply a med-

ical emergency supply (USP) is suggested.

WARNING

Device failure due to incorrect storage and usage

conditions!

►Store and operate the product only within the

specified environmental conditions.

CAUTION

Restricted function if third party devices are used!

►Use the product only with the recommended

components and accessories.

►Full functionality is only guaranteed if the rec-

ommended components and accessories are

used.

5

3. Product description

3.1 Scope of supply

3.2 Components required for operation

The camera head (PV481/PV482/PV485) is used for visualization during

endoscopic surgical procedures.

The camera head is intended for use with the following components:

■Camera control unit PV480 or PV630

■Disposable sterile cover JG904

■LED light source OP950

These components are optimally aligned with one another and therefore

offer the best possible quality and unlimited functionality.

3.3 Intended use

The Full HD CMOS camera control unit (PV480) serves the 2D HD visual-

ization of the interior of the body during minimally invasive surgical pro-

cedures and endoscopic examinations.

The Full HD CMOS camera control unit is only used for visualizing and not

for diagnosis.

Endoscopic indications

■Minimal invasive surgery

■Surgery

■General endoscopy

Contraindications

The use of the Full HD CMOS camera components and its accessory is con-

traindicated if endoscopic procedures are contraindicated for any reason.

As is appropriate with any surgical procedure, consideration must be given

to patient size and workspace volume when using the Full HD CMOS cam-

era components.

Depending on the patient’s disease, there may exist contraindications that

rely on the general condition of the patient or the specific disease pattern.

The decision to perform an endoscopic procedure rests with the responsi-

ble surgeon and should be made on the basis of an individual risk-benefit

analysis.

3.4 Operating principle

The camera heads within the scope of these instructions for use can be

used with the PV480 and PV630 camera control units and may only be

connected to this unit.

The combination of camera control unit and camera head result in a cam-

era based on CMOS technology.

In combination with a suitable monitor, the camera provides two-dimen-

sional images.

The camera head features four configurable camera head buttons that can

be used to control image display, record images and video, or to navigate

and change the settings in the configuration menu of the camera control

unit.

The camera heads are intended for use with the applicable sterile cover.

(B. Braun JG904).

Camera head buttons

The camera head buttons have different functions depending on the oper-

ating mode.

The assignment of the buttons is always synchronous with the assignment

of the buttons on the front of the camera control unit.

Different functions can be assigned for a short press of the button

(<2 sec.) and a long press of the button (≥2 sec.).

The procedure for changing the assigned functions is described in the

instructions for use of the respective camera control unit.

Designation Art. no.

Full HD CMOS camera head with pendulum coupler

– or –

Full HD CMOS camera head with zoom coupler

– or –

Full HD 3CMOS camera head with zoom coupler

PV481

PV482

PV485

Instructions for use TA014624

CAUTION

If the recommended components are not used, the

following errors/complications may occur, among

others:

■Incorrect color display

■No/incorrect display of the camera menu

■Restricted operating function from the camera

head

■Increased fogging on the optics

6

Aesculap®

2D camera heads PV481, PV482, PV485

Button assignment in live mode

Button assignment when on-screen display is active

When on-screen display is active, the buttons are used to navigate the

menu until the menu is left.

Button assignment when on-screen keyboard is active

When the on-screen keyboard is active, the buttons are used to navigate

the keyboard until the keyboard is left.

4. Preparation

If the following instructions are not observed, the manufacturer assumes

no responsibility for possible consequences.

Before installation and use, ensure that the:

■electrical installations comply with the relevant technical regulations,

■relevant regulations concerning fire and explosion protection are

observed.

Note

For the safety of the user, it is essential that the mains power cord and,

especially, the protective earth connection are intact. In many cases defec-

tive or missing protective earth connections are not registered immedi-

ately.

The button assignment in live mode

depends on whether a standard profile

or user profile is set.

If a user profile is set, the buttons can

be assigned individually, however the

assignment for entering the camera

control unit menu cannot be changed.

In standard profile, the buttons are

assigned as follows:

Short press of

button Long press of

button

Not working Open menu

Zoom White balance

Light source on Light source

on/off

Single frame

image

Video recording

start/stop

Short press of button Long press of but-

ton

up / control + Leave the menu

right / next level / across /

save control setting

down / control – / on

left / back a level / save

control etting

Short press of button Long press of but-

ton

up Not working

right Confirm/enter

down Not working

left Not working

WARNING

Risk to patient from misdirected leakage current

due to incorrect or defective earthing!

►Do not touch the product and patient at the

same time.

WARNING

Risk to patient due to failure of a device!

►Keep an operationally ready replacement device

on hand and if necessary change to conventional

surgical methods.

7

Note

The product including the camera cable is fragile when bent, kinked,

twisted, pulled, or pressed.

Note

Handle the camera head and camera cable with care. Do not exert any

mechanical forces and avoid mechanical impacts.

Note

Connect the equipotential bonding terminals of all equipment used with

the equipotential bonding strip see IEC 60601-1-1 / EN 60601-1-1 or in

accordance with national standards.

Note

Ensure that the corresponding interconnection conditions, standards and

respective national deviations are observed.

4.1 Combination with medical electrical equipment

The product can be combined with components from other manufacturers

provided that all components are compliant with the medical electrical

equipment safety requirements according to IEC 60601-1.

It is the operator’s responsibility to check and make sure that the system

is and remains fully operational.

When using devices from different manufacturers and when operating an

endoscope and/or endoscopic accessories together with medical electrical

equipment, it must be ensured that the applied part is properly isolated:

Type CF, defibrillation-proof.

4.2 Inspections

Carry out the following inspection steps before reprocessing and immedi-

ately before use of the device:

Inspection of the glass surfaces

►Before each use, inspect the camera head for damage such as rough

surfaces, sharp edges or protrusions to avoid injuries to the patient.

►Perform a visual inspection of the glass surfaces. The surfaces must be

clean and smooth.

If there are impairments/damage, see Troubleshooting list.

4.3 First use

WARNING

Danger of explosion from a device that is improp-

erly set up!

►Make certain that the power plug is connected

to the power supply outside of any areas where

there is a risk of explosion.

►Do not use the product in potentially explosive

areas or close to highly flammable or explosive

gases (e.g. oxygen, anesthetic gases).

WARNING

Risk to patient and user due to condensation and

short-circuit!

►Before putting into operation make sure that all

components used have enough time to adjust to

the changed environmental conditions.

WARNING

Risk of injury to the eyes!

►Do not insert the light guide into the light

source during the check of the fibers.

WARNING

Risk of infection and injury!

►Do not use products with damaged fiber optics,

damaged glass surfaces or stubborn deposits

which cannot be removed by cleaning.

WARNING

Risk to patient due to use of damaged products!

►Do not use products if they have sharp edges or

other hazardous surface damage.

CAUTION

Risk to persons and risk of damage to equipment

due to improper cable routing!

►Lay all cables and leads so that they do not pres-

ent a tripping hazard.

►Do not place objects on the cables.

CAUTION

Risk to patient due to poor/lack of vision!

►Adjust the monitors and display elements so

that they are highly visible to the user.

CAUTION

Interference of high frequency energy with the

device!

►Do not use any mobile or portable equipment

that emit high-frequency energy (e.g. mobile

phones, cell phones, GSM phones) in the vicinity

of the product.

WARNING

Risk of injury and/or product malfunction due to

incorrect operation of the medical electrical sys-

tem!

►Follow the instructions for use of all products

required.

8

Aesculap®

2D camera heads PV481, PV482, PV485

5. Working with the camera heads

5.1 General notes on use

The camera cable is fragile when bent, kinked, twisted, pulled, or pressed.

Observe the maximum bend radius of 7 cm and handle the cable with care.

Do not make any changes to the cable and do not load with sharp-edged

objects.

5.2 System set-up

Note

In combination with the camera control unit, PV480 or PV630, the endo-

scope is classed as a type CF defibrillation-proof applied part.

Note

Before application of endoscopic high frequency surgery (HF surgery) pre-

pare the patient accordingly.

Note

Take measures to remove or avoid formation of combustible gases (e.g.

gastro-intestinal tract/colonoscopy, urinary bladder/transuretheral resec-

tion).

Connecting the accessories

Combinations of accessories that are not mentioned in the present

instructions for use may only be employed if they are specifically intended

for the respective application, and if they do not compromise the perfor-

mance and safety characteristics of the products.

Any equipment connected at the interfaces must also demonstrably meet

the respective IEC standards (e.g. IEC 60950 for data processing equip-

ment, and IEC/DIN EN 60601-1 medical electrical equipment).

All configurations must meet the basic standard IEC/DIN EN 60601-1. The

person connecting the devices is responsible for the configuration and

must ensure that the basic standard IEC/DIN EN 60601-1 or the corre-

sponding national standards are met.

►Please contact your B. Braun/Aesculap partner or Aesculap Technical

Service, (address: see Technical Service) with any inquiries in this

respect.

WARNING

Risk of infection due to unsterile parts!

►Ensure that unsterile components do not enter

the sterile area.

►Process products and accessories that are deliv-

ered unsterile before use and only use them with

sterile accessories.

WARNING

Risk of infection due to unsterile, soiled or contam-

inated products!

►Only use the camera head in the sterile area if

it is in sterile condition. To do so, use the camera

head with the correctly applied sterile cover or

after sterilization process.

WARNING

Risk to patient due to addition of leakage currents!

►If the product is used with medical electrical

equipment and/or power-driven endoscope

accessories, the leakage currents can multiply.

WARNING

Risk to patient and user from burns, sparks or

explosion!

►When using a high frequency surgical device

during an endoscopic procedure, observe the

safety instructions of the corresponding

instructions for use.

WARNING

Risk of injury due to improper use!

►Observe the intended use of the product.

►Do not use the endoscope as a lever.

CAUTION

Interference of electromagnetic emissions with the

image quality (e.g. minor banding, minor color

changes on the monitor image)!

►Check the image quality if used in combination

with additional peripheral devices (e.g. monitor,

video equipment).

DANGER

Risk of injury due to unapproved configuration

using additional components!

►For all components used, ensure that their clas-

sification matches that of the applied part (e.g.

type CF defibrillation-proof) of the respective

device.

9

5.3 Function checks

Note

Only perform the surgical procedure if all of the components being used are

in a flawless condition.

Note

Before each use, after a power failure or any interruption, the functionality

of all connected devices must be checked and all connections must be

checked to see they are correct.

Note

The endoscope image must be focused, bright and clean at an appropriate

working distance.

Note

Do not continue to use damaged products.

5.4 Safe operation

Excessive temperatures in combination with light sources

Light sources, especially high-power light sources, emit large amounts of

light energy and thermal energy. The light guide connector and the distal

end of the endoscope may therefore become extremely hot.

Risks from use of light sources:

■Irreversible tissue damage or unwanted coagulation to the patient or

user

■Burns or thermal damage to surgical equipment (e.g. surgical drapes,

plastic materials, etc.)

■If the light source fails during use, this may endanger the patient.

Therefore keep an operationally ready replacement light source on

hand.

Safety precautions

►Do not illuminate the inside of the patient for longer than necessary

with the light source.

►Use the automatic light intensity control or set the light source so that

a bright, well-lit image is visible with the lowest possible light inten-

sity.

►Do not allow the distal end of the endoscope or light guide connector

to come into contact with patient tissue or with combustible or heat-

sensitive materials.

►Do not touch the distal end of the endoscope.

►Remove contaminations on the distal end surface or light emission sur-

face.

WARNING

Risk to patient due to incorrectly displayed image!

►Remove any contaminations on the optical sur-

faces (camera head) before and during the pro-

cedure. Clean the endoscope tip with a cloth

soaked in alcohol (70 % ethanol) or with a neu-

tral cleaning agent.

►Prior to application and after changing the set-

tings, check the correct display of the live

image. If necessary, perform white balance.

WARNING

Risk to patient and user from functional failure or

electric shock!

►Use only dry components (e.g. plug connector

for camera control unit, optical lens).

WARNING

Risk of burns due to development of heat at the tip

of the endoscope!

►Do not put down the endoscope on the patient

during use.

►In the patient's abdominal cavity, always leave a

sufficient distance between the optical lens and

the tissue surfaces and mucous membranes of

the patient.

►Use automatic light intensity control or set the

light source so that a bright, well-lit image is

visible with the lowest possible light intensity.

►Switch off the light source if the illumination is

no longer needed or if the endoscope is out of

the patient for a longer period of time.

WARNING

Risk of injury due to excessive temperature!

►Do not touch the light guide connector or distal

end of the endoscope during use or immediately

after use.

WARNING

Risk of injury and/or malfunction!

►Always carry out a function check prior to using

the product.

WARNING

Risk of injury from burns and unwanted deep pen-

etration and risk of damage to product!

►Only switch on high frequency current when the

corresponding applied part (electrode) can be

seen through the endoscope and there is no

contact between the two.

WARNING

Risk of infection due to contamination of the ster-

ile area!

►Fix the camera cable (unsterile) with sterile

cover (sterile) sufficiently nearby in the opera-

tion area.

10

Aesculap®

2D camera heads PV481, PV482, PV485

Note

The current assignment of the buttons is displayed on the screen as "Cam-

era head information" after opening the camera menu.

Connection to camera control unit

►Insert the connection plug fully into the connection socket of the cam-

era control unit until it engages in place.

6. Reprocessing procedure

WARNING

Risk of injury due to misdirected leakage currents!

►Before thoracic or cardiothoracic surgery, deac-

tivate implanted defibrillators (ICD).

►Before any kind of defibrillation, remove the

used camera head from the patient.

WARNING

Risk of infection/injury to patients and users!

►Only use the sterile cover once.

►Do not clean the sterile cover with ultrasound.

►Do not reprocess the sterile cover.

WARNING

Risk to patient from gas embolism!

►Avoid overinsufflation (e.g. with air or inert gas)

before high frequency surgery.

WARNING

Risk to patient from damage to the optical lens!

►Withdraw the endoscope slowly from the used

trocar.

►If a trocar with a manual opening valve is being

used, only withdraw the endoscope from the

trocar when the valve is open.

WARNING

Risk of infection due to unsterile cover or medical

device!

►Replace the sterile cover or the camera head if

it falls on the ground or if it is touched by

unsterile objects/persons.

CAUTION

Malfunction in connection with magnetic reso-

nance!

►Do not use the product in a magnetic resonance

environment.

WARNING

Risk of infection due to an incorrectly reprocessed

product!

►Adhere to national statutory regulations,

national and international standards and direc-

tives, and local, clinical hygiene instructions for

reprocessing.

►For patients with Creutzfeldt-Jakob disease

(CJD), suspected CJD, or possible variants of

CJD, observe the relevant national regulations

concerning the reprocessing of products.

►The camera head is not autoclavable. Therefore,

the camera head and corresponding sterile cover

must not be used in patients suspected of having

Creutzfeldt-Jakob disease or who have already

been diagnosed with Creutzfeldt-Jakob disease.

►Mechanical reprocessing should be favored over

manual cleaning as it gives better and more reli-

able results.

►Successful reprocessing of this medical device

can only be ensured through a validated repro-

cessing procedure. The operator/reprocessing

technician is responsible for this.

WARNING

Risk of infection for patients and/or user due to:

►Residues of cleaning and disinfectants at the

product.

►Insufficient or incorrect cleaning and disinfec-

tion of the product and accessories.

CAUTION

Risk of damage to and malfunction of the device

due to incorrect reprocessing!

►Do not autoclave the product.

CAUTION

Risk of defects, consequential damage or a short-

ened product service life!

►Follow and observe the manufacturer's require-

ments for reprocessing.

11

6.1 General information

Dried or affixed surgical residues can make cleaning more difficult or inef-

fective and lead to corrosion. Therefore the time interval between appli-

cation and reprocessing should not exceed 6 h; also, neither fixating pre-

cleaning temperatures >45 °C nor fixating disinfecting agents (active

ingredient: aldehydes/alcohols) should be used.

Excessive neutralizing agents or basic cleaners may result in a chemical

attack and/or fading and the laser marking becoming unreadable either

visually or by machine in case of non stainless steel.

Residues containing chlorine or chlorides, e.g., in surgical residues, medi-

cines, saline solutions, and in the service water used for cleaning, disin-

fection, and sterilization, will cause corrosion damage (pitting, stress cor-

rosion) and result in damage to the products in case of non stainless steel.

These must be removed by rinsing thoroughly with demineralized water

and then drying.

Perform additional drying, if necessary.

Only process chemicals that have been tested and approved (e.g. VAH or

FDA approval or CE mark) and which are compatible with the product’s

materials according to the chemical manufacturers’ recommendations

may be used for reprocessing the product. All the chemical manufacturer's

application specifications must be strictly observed. Failure to do so can

result in the following problems:

■Optical material changes (e.g. fading or discoloration) in titanium or

aluminum. For aluminum, the application/process solution only needs

to be pH >8 to cause visible surface changes.

■Material damage (e.g. corrosion, cracks, fracturing, premature aging, or

swelling)

►Do not use metal cleaning brushes or other abrasives that would dam-

age the product surface and could cause corrosion.

►For further detailed information on hygienically safe and material-pre-

serving/ value-preserving reprocessing, see www.a-k-i.org link to Pub-

lications, Red Brochure – Proper maintenance of instruments.

6.2 Dismantling prior to carrying out the reprocessing

procedure

►Unplug the camera plug from the camera control unit.

►Remove the sterile cover from the camera head and dispose of it

according to regulations. The sterile cover is only intended for single

use.

►Remove the endoscope, light guide and all detachable parts.

6.3 Preparations at the place of use

►Remove any visible surgical residues as much as possible with a damp,

lint-free cloth. Use a soft cloth for this to avoid scratching the optical

lens.

►Pre-clean all used parts of the fully disassembled product at the oper-

ating table at the conclusion of the surgery by wiping with a lint-free

wipe wetted with an enzymatic cleaning solution until visibly clean.

►Place the dry product in a sealed waste container and forward it on for

cleaning and disinfection within 6 hours.

6.4 Preparation before cleaning

►Non-fixating/NaCl-free pre-cleaning is mandatory immediately after

use.

6.5 Cleaning/disinfection

The effectiveness of the following procedures:

■Manual cleaning and manual disinfection

■Automated cleaning and thermal disinfection

■Sterilization

as described in this document, has been fully validated.

It is the operator’s responsibility to introduce, document, implement, and

maintain a validated reprocessing procedure. Make sure that the equip-

ment used for reprocessing is properly maintained.

The reprocessing procedure described in this document consists of the fol-

lowing steps:

■Pre-cleaning immediately after use

■Cleaning and disinfection (manual or automated) and

■Sterilization.

WARNING

Damage to the product due to improper reprocess-

ing!

►Do not, under any circumstances, clean or disin-

fect the product in an ultrasonic cleaning bath.

►Use cleaning and disinfecting agents which are

suitable and approved for the present product.

►Observe the manufacturer’s cleaning and disin-

fecting instructions regarding concentration,

temperature and exposure time.

►Only reconnect the system to power when all

cleaned parts are completely dry.

►Never autoclave the product.

12

Aesculap®

2D camera heads PV481, PV482, PV485

Product-specific safety instructions for the reprocessing procedure

Note

There may be significant discoloration of the camera head when using

Cidex OPA. However, this discoloration has no influence on the functional-

ity or safety of the product.

6.6 Manual cleaning and disinfecting

Post use and pre-cleaning activities

►Pre-clean the device immediately after use.

►Remove and discard the sterile drape, if present.

►Decouple the endoscope from the optocoupler.

►Uncouple the camera head from the controller.

►Pre-clean all used parts of the fully disassembled product at the oper-

ating table at the conclusion of the surgery by wiping with a lint-free

wipe wetted (i.e. wetted but not dripping; squeeze out excess solution)

with an enzymatic cleaning solution until visibly clean. Before wetting

the lint-free wipe with the enzymatic clean solution, the solution

should be prepared according to the manufacturer’s instruction.

►Arrange for reprocessing, ensuring that all of the device components

are reprocessed within 6 hours.

DANGER

Risk of electric shock and fire hazard!

►Unplug the device before cleaning.

►Do not use flammable or explosive cleaning or

disinfecting solutions.

CAUTION

Damage to the product due to inappropriate clean-

ing/disinfecting agents and/or excessive tempera-

tures!

►Use cleaning and disinfecting agents according

to the manufacturer’s instructions. The cleaning

and disinfecting agent must be approved for

plastics and high-grade steel, and it must not

attack softeners (e.g. silicone).

►Observe specifications regarding concentration,

temperature and exposure time.

►Do not exceed the maximum permitted cleaning

temperature of 100 °C.

13

Manual cleaning with immersion disinfection

FD-W Fully desalinated water (demineralized, low microbiological contamination, max. 10 germs/ml and low in endotoxins, max. 0.25 Endo-

toxin units/ml)

1) Phase does not apply to US market

Phase I: Cleaning

►Prepare the cleaning solution according to the manufacturer’s instruc-

tions.

►Fully immerse all parts of the fully disassembled device that were used

in the cleaning solution bath for two (2) to five (5) minutes. All acces-

sible surfaces must remain immersed in the cleaning solution bath

throughout the entire cleaning time.

►After soaking in the cleaning solution, clean all external surfaces-

while the items are fully emerged in the cleaning solution – using a

clean, lint-free, soft, non-sterile cloth or a soft bristled brush until all

visible soiling is removed:

– Brush for at least one (1) minute or until no more residues can be

removed.

– During cleaning, move non fixed components 3 times in each direc-

tion and as far as possible.

►Thoroughly rinse all surfaces of products with hidden crevices, lumens

with working channels, or complex geometry five (5) times. Use a dis-

posable 50 ml syringe.

Phase II: Rinse

►Fully immerse all parts in a tap water bath (<45 °C/113 °F) and thor-

oughly rinse all accessible surfaces twice for a minimum of one (1)

minute each.

►Move non fixed components 3 times in each direction and as far as

possible.

►Thoroughly rinse all hidden crevices, lumens or complex geometry at

least three times:

– Use a disposable 50 ml syringe.

– Use fresh water for each rinse.

– Allow water to drip off for a sufficient length of time.

Phase III: Disinfection

►Immerse all parts completely in disinfectant solution for at least

12 minutes. All accessible surfaces must remain immersed in the dis-

infectant solution bath throughout the entire disinfecting time.

►Remove all adherent air bubbles from the component surfaces

►Thoroughly rinse all surfaces of products with hidden crevices, lumens

with working channels, or complex geometry five (5) times. Use a dis-

posable 50 ml syringe.

►Move non fixed components 3 times in each direction and as far as

possible.

Phase IV: Rinse

►Fully immerse all parts in a tap water bath (<45 °C/113 °F) and thor-

oughly rinse all accessible surfaces twice for a minimum of one minute

each.

►Move non fixed components 3 times in each direction and as far as

possible.

►Thoroughly rinse all hidden crevices, lumens or complex geometry at

least three times:

– Use a disposable 50ml syringe.

– Use fresh water for each rinse.

– Allow water to drip off for a sufficient length of time.

Phase Step T [°C/°F] t [min] Water quality Chemicals

I Cleaning as per manufac-

turer’s instruction

2-5 Tap water Enzymatic cleaning agent (Cidezyme/Enzol)

II Rinse 2x <45/113 2x ≥1 Tap water –

III Disinfection1) as per manufac-

turer’s instruction

12 as per manufac-

turer’s instruction

0.55 % Orthophtaldehyde solution (Cidex OPA)

IV Rinse 2x1) <45/113 2x ≥1 Tap water –

VFinalRinse <45/113 ≥1 FD-W –

VI Drying ––––

CAUTION

Damage to the product due to improper handling!

Scratch-sensitive surface.

►Handle the device with appropriate care.

►Do not use metal brushes, metal objects or abra-

sive cleaners.

14

Aesculap®

2D camera heads PV481, PV482, PV485

Phase V: Final rinse

►Fully immerse all parts in a fully desalinated water bath

(<45 °C/113 °F) and thoroughly rinse all accessible surfaces for a min-

imum of one minute.

►Move non fixed components 3 times in each direction and as far as

possible.

►Thoroughly rinse all hidden crevices, lumens or complex geometry at

least three times.

– Use a disposable 50 ml syringe.

– Use fresh water for each rinse.

– Allow water to drip off for a sufficient length of time.

Phase VI: Drying

►Thoroughly dry all parts with a clean, lint-free wipe or a lint-free sur-

gical towel.

►Dry all accessible surfaces, especially the channels with medical-qual-

ity filtered compressed (pmax = 0,5 bar).

►Visually inspect the device in a well-lit area; they should be completely

clean and dry. If necessary please use a magnifying glass and repeat

the manual cleaning performance.

This concludes the manual cleaning and disinfection process.

6.7 Mechanical cleaning/disinfecting with manual pre-cleaning

Post use and pre-cleaning activities

►If applicable, flush not observably surfaces primarily with deionized

water e.g. with a single use syringe.

►Remove as far as possible visible residues with a moist lint free wipe.

Use an enzymatic cleaning solution to moisten the cloth that was pre-

pared in accordance with the instructions of the manufacturer.

►Place the device in a dry and closed disposable container and transport

it within 6 hours to cleaning and disinfection.

Manual pre-cleaning

Phase I: Cleaning

►Fully immerse all parts of the fully disassembled device that were used

in a cleaning solution bath (<40 °C) for ten (10) to thirty (30) minutes.

►Immerse all accessible surfaces in the cleaning solution bath through-

out the entire cleaning time.

►While the components soak in the solution, use a soft wipe or soft

brush to remove all visible residues from all exterior surfaces of the

components.

►Move non fixed components 5 times in each direction and as far as

possible.

Phase 2: Rinse

►Fully immerse all parts in a tap water bath (<45°C/113 °F) and thor-

oughly rinse all accessible surfaces twice for a minimum of one (1)

minute each:

– Use fresh water for each rinse.

– Move non fixed components 5 times in each direction and as far as

possible.

– Allow water to drip off for a sufficient length of time.

Phase Step T [°C/°F] t [min] Water quality Chemicals

I Cleaning <45/113 10-30 Tap water Enzymatic cleaning agent (Cidezyme/Enzol)

II Rinse 2x <45/113 2x ≥1 Tap water –

15

Mechanical alkaline cleaning and thermal disinfecting

►Use a washer/disinfector that has been validated as effective and

meets the performance requirements of ISO 15883-1 (or the respective

country specific version thereof)

►For reprocessing, use the camera tray, which is used without a lid. This

tray is only suitable for the camera and not for instruments.

►Place the device in the provided reusable camera tray. Avoid areas that

cannot be reached during rinsing.

►Place the tray in the automatic washer/disinfector in a suitable carrier

that ensures both the protection of the instrument and access to sur-

faces for cleaning. No lid will be used for the tray.

►Start the cleaning cycle as described (see table) in accordance with the

manufacturer’s instructions and instruction for use for the washer/dis-

infector.

►Remove the tray and the devices from automatic washer.

►Visually inspect the device in a well-lit area; they should be completely

clean, dry and undamaged.

►Use a magnifying glass. Repeat the cleaning process if necessary.

Immediately set aside any damaged components.

6.8 STERRAD sterilisation

The STERRAD® sterilization systems, manufactured by Advanced

Sterilization Products (ASP), use low-temperature, hydrogen peroxide gas

plasma technology for terminal sterilization of properly cleaned, rinsed,

and dried reusable medical devices.

►Refer to the STERRAD® Sterilization Systems User Guide for detailed

instructions for use of any STERRAD® unit and ASP’s STERRAD Sterility

Guide (SSG) at www.sterradsterilityguide.com or contact ASP cus-

tomer service.

Performing sterilization

Note

STERRAD® sterilization may result in cosmetic device changes that do not

necessarily affect the device function.

►Place all parts in a cleaning and storage basket.

►Place a STERRAD® indicator strip in the basket.

►Assemble sterilization container JM441 according to manufacturer’s

instruction.

►Place the basket in the sterilization container JM441.

►Load the container in the sterilizer:

– Position the container such that the plasma can fully surround it.

– Load only one container per cycle in the chamber.

– Leave the other shelf empty.

►Start the sterilization cycle in accordance with the manufacturer’s

instructions and instructions for use for the steam sterilizer.

STERRAD® sterilization was validated for the following cycles:

– STERRAD® 100S short cycle

– STERRAD® NX standard cycle

– STERRAD® 100NX standard cycle

►Remove the sterilized products from the sterilizer.

►Ensure that the products remain sterile after reprocessing.

This concludes sterilization.

Phase Step T [°C/°F] t [min] Water quality Chemicals/Note

I Prerinse <25/77 3 Tap water –

II Cleaning 55/131 10 Deionized water Alkaline Detergent

Neodisher Mediclean forte 0.5 %

III Intermediate rinse >10/50 1 Deionized water –

IV Thermal disinfection 90/194 5 Deionized water –

VDrying – – – According to the program of the washer/disinfector

CAUTION

Loads containing moisture may cause a cycle can-

cellation!

►Thoroughly dry the product before loading into

the STERRAD® sterilizer.

16

Aesculap®

2D camera heads PV481, PV482, PV485

6.9 Material-compatible cleaning and disinfecting

agents

■Wipe disinfection:

– Meliseptol HBV tissues 50 % Propan-1-ol (B. Braun)

– Chlorine Disinfection (Wetwipe)

■Manual immersion disinfection: Stabimed (B. Braun)

6.10 Inspection, maintenance and checks

►Inspect the product after each cleaning and disinfecting cycle to be

sure it is: clean, functional, and undamaged.

►Check the product for damage or excessive heating.

►Set aside the product if it is damaged.

6.11 Storage

►Store sterile products in germ-proof packaging, protected from dust, in

a dry, dark, temperature-controlled area.

7. Service

Send damaged products to the manufacturer or authorized repair center.

Authorized repair centers can be inquired about from the manufacturer.

Note

If for urgent reasons it is not possible to thoroughly clean/disinfect and

sterilize the product, reprocess the product as far as possible and label it

accordingly.

The specialized repair company may refuse to repair soiled or contaminated

products for safety reasons.

The manufacturer reserves the right to return contaminated products to

the sender.

8. Maintenance

This product is maintenance-free. It does not contain components which

have to be maintained by the user or manufacturer.

However the manufacturer requires that a qualified person or a hospital

technician inspects the product regularly in a preventive safety inspection.

The product should be inspected at least once every 12 months.

In case of preventative safety inspections, no special conditions and mea-

sures have to be observed.

During the inspection, the following tests have to be done according to

section 5 of DIN DIN EN 62353/IEC 62353:

■5.2 Visual inspection

■5.3.2 Measuring of protective earth resistance (only applicable for

devices of protection class I)

■5.3.3 Measurement of leakage currents

■5.3.4 Measurement of insulation resistance

According to section 6 of DIN EN 62353/IEC 62353, the test results must

be fully recorded in a test report, which can be taken from Annex G of the

standard.

After performing the preventive safety inspection, a functional test is to

be carried out.

For relevant services contact your national B. Braun/Aesculap agency, see

Technical Service.

CAUTION

Damage to product due to improper storage!

►Store the product protected from dust in a dry,

well ventilated, and temperature-controlled

room.

►Store the product protected from direct sun-

light, high temperatures, high air humidity or

radiation.

►Protect the product from direct UV light, radio-

activity or strong electromagnetic radiation.

►Store the product separately or use containers

in which it can be fixed in place.

►Always transport the product with care.

CAUTION

Damage to product due to improper handling!

►Do not drop the camera head and handle it with

care.

►When transporting the camera head over

thresholds or uneven ground, store the camera

head securely.

CAUTION

Damage to the optical lens due to inappropriate

transport packaging!

►Use the tray only for the camera head and not

for instruments.

►Use the tray for the camera head only within the

clinic.

►Only place a disinfected camera head in the

tray.

WARNING

Risk of infection due to soiled or contaminated

products!

►Clean, disinfect and sterilize the product and/or

any accessories thoroughly before sending.

►Prior to sending, remove the sterile cover from

the camera head.

►Select suitable and safe packaging (ideally the

original packaging).

►Package the product in such a way that the

packaging does not become contaminated.

17

9. Troubleshooting list

9.1 Repairs

For repairs, contact the manufacturer or authorized repair center. Autho-

rized repair centers can be inquired about from the manufacturer.

For a fast processing of your service requests, send in the product indicat-

ing:

■Article number (REF)

■Serial number (SN)

■Detailed description of defects

Note

If a component of the visualization system is replaced (e. g. service,

upgrade), the system start-up process must be performed again. It is also

recommended to perform a safety inspection after any maintenance or

replacement of a device.

10. Technical Service

Note

Service and repair work must only be carried out by authorized trained per-

sonnel. For service and repairs, please contact your national

B. Braun/Aesculap agency.

Modifications carried out on medical technical equipment may result in

loss of warranty rights and applicable licenses.

Problem Possible cause Remedy

Image cloudy Glass surfaces soiled Clean the glass surfaces according to the Cleaning and Disin-

fection section.

Stubborn residue on the glass surfaces Remove residues according to the Cleaning and Disinfection

section; check water quality.

Image too dark, too little

illumination

Glass surfaces soiled Clean the glass surfaces according to the Cleaning and Disin-

fection section.

Light guide dirty, defective Check light guide (e. g. illuminate onto a white surface).

Excessive chloride concentration Check water quality.

Heavy metal ions and/or silicates, increased content of

iron, copper, manganese in water

Check water quality; if applicable, only use deionized (fully

desalinated) water.

Too high concentration of mineral substances (e.g. cal-

cium) or organic substances

Contaminated cleaning/disinfecting solutions, too fre-

quent use

The cleaning and disinfecting solutions should be replaced

regularly.

Extraneous rust, (e.g. resulting from previously dam-

aged or non-corrosion-resistant instruments being

reprocessed at the same time)

Check supply systems; in case of joint reprocessing, check

material compatibility and for existing damage, and avoid

mutual contact.

Contact corrosion Avoid contact with other components.

WARNING

Risk of injury and/or malfunction!

►Do not modify the product.

CAUTION

Malfunction of the product due to damage in

transport!

►Select suitable and safe packaging (ideally the

original packaging).

►Keep the original packaging for possible returns

in case of service.

►Package the product in such a way that the

packaging does not become contaminated.

18

Aesculap®

2D camera heads PV481, PV482, PV485

Service address

AESCULAP FLEXIMED GmbH

Robert-Bosch-Straße 1

79211 Denzlingen

Germany

Phone: +49 (0) 7666 / 9321-0

E-mail: [email protected]

Web: www.aesculap-fleximed.de

Other service addresses can be obtained from the address indicated above.

11. Accessories/Spare parts

12. Technical data

Classification acc. to Directive 93/42/EEC

12.1 Ambient conditions

Art. no. Designation

JG904 Disposable sterile cover, pack of 25

Art. no. Designation Class

PV481 Full HD CMOS camera head with pendulum

coupler

I

PV482 Full HD CMOS camera head with zoom coupler I

PV485 Full HD 3CMOS camera head with zoom coupler I

JG904 Disposable sterile cover, pack of 25 IIa

Protection rating IPX7

Sensor format Native Full HD 1/3"

Scanning system Progressive scan

Frequency 50 Hz or 60 Hz

Protection class (according to

IEC/DIN EN 60601-1)

I

Weight (excl. cable) ■PV481: 180 g

■PV482: 294 g

■PV485: 380 g

Length of camera cable 3,5 m

Applied part Type CF, defibrillation-proof (in combi-

nation with camera control unit PV480

or PV630)

Dimensions (L x W x H) ■PV481: 50 mm x 38 mm x 171 mm

■PV482: 188 mm x 43 mm x 43 mm

■PV485: 188 mm x 46 mm x 47 mm

EMC IEC/EN/DIN 60601-1-2

Conforming to standard IEC/EN/DIN 60601-1

CISPR 11 Class A

Operation Storage and transport

Temperature

Relative

humidity

Atmospheric

pressure

35 °C

10 °C

50 °C

-10 °C

This manual suits for next models

2

Table of contents

Languages:

Other Aesculap Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Monaghan

Monaghan Aerobika Instructions for use

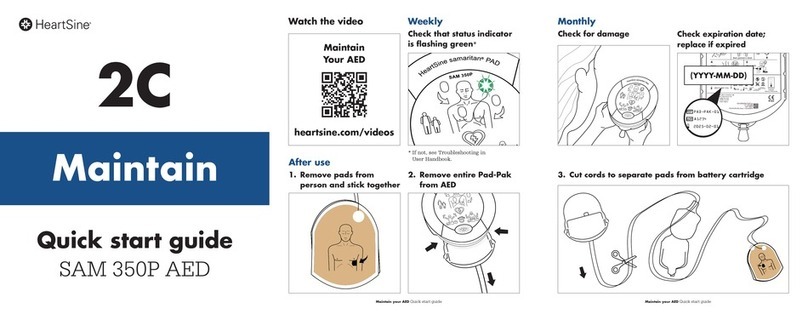

HeartSine

HeartSine SAM 350P AED quick start guide

Pari

Pari eflowrapid 178G1005 Instructions for use

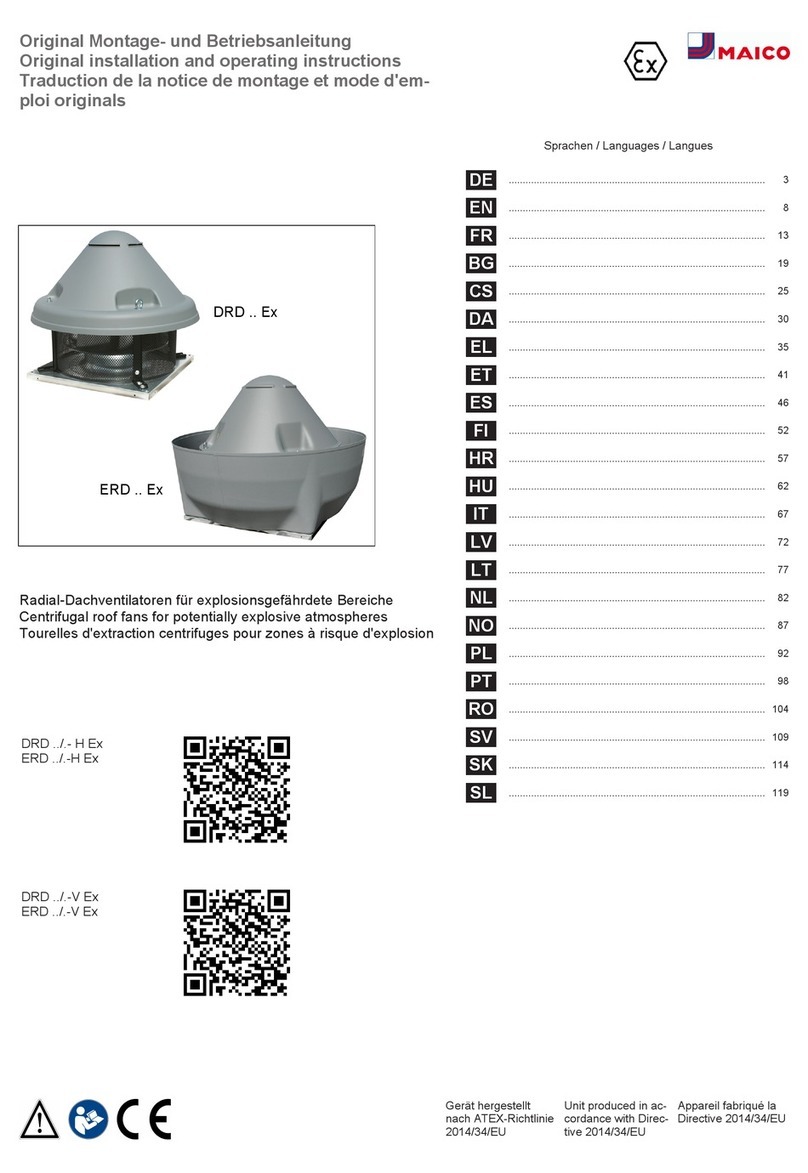

Maico

Maico DRD Ex Series Original installation and operating instructions

Breg

Breg 100628-020 Instructions for use

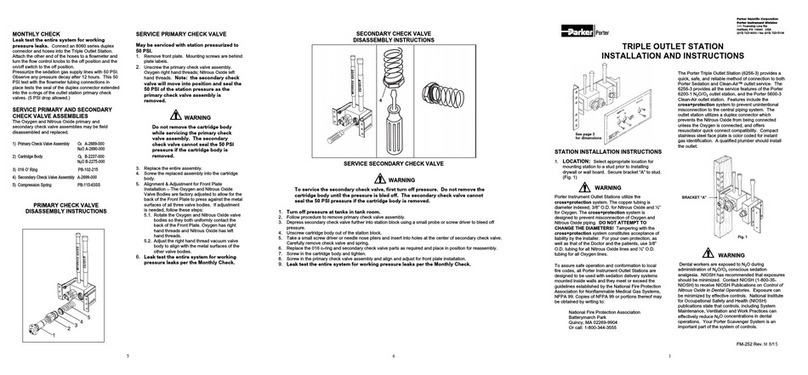

Porter

Porter 6256-3 Installation and instructions